Modern networks and standardized communication protocols enable smoother and more-efficient building operations, enhanced fault detection and troubleshooting, and reduced system-installation costs. Still, prejudice against network connections persists within the industry because they are considered less reliable than hard-wired point connections. Many designers require control points to be hard-wired, allowing only monitoring data to be routed through network connections. This can be confusing to operations-staff members, who may find duplicate points with different values or statuses in databases. Additionally, some equipment and devices may not operate properly with such dual connectivity.

While some control-system products do not meet expectations for reliability in network connections, the primary reason for network-reliability issues in building control systems often is designers providing inadequate standards, direction, and oversight regarding configuration of network connections. Consider the following real-life example.

The Network-Configuration Specification

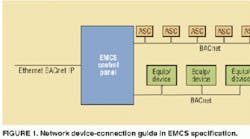

For a recent office-building control retrofit, the energy-management-and-control-system (EMCS) specification required network connection of all network-capable equipment and devices. The controls were required to employ native BACnet communications. For uniformity and ease of connection, only BACnet devices and equipment were to be selected. The specification provided guidance on control-network configuration, with sample configuration diagrams (Figure 1) provided.

In Figure 1, "EMCS control panel" is any EMCS panel that controls equipment such as air handlers, chillers, and boilers. The blocks labeled "ASC" are application-specific controllers that typically control variable-air-volume (VAV) boxes, while the blocks labeled "Equip/device" represent third-party equipment or devices such as variable-frequency drives (VFDs), chillers, and boilers that are to be network-connected to the system. Because network connections and capabilities vary by EMCS manufacturer, the configuration diagram served to show the intent of the network topology. The specification required each EMCS equipment controller to be interconnected via Ethernet BACnet Internet protocol (IP) and all devices to be connected via BACnet master-slave/token-passing (MS/TP) networks. The specification also required that all EMCS-controlled equipment be on a network originating at the panel providing control of the equipment. A schematic of the actual network configuration with all equipment and communication details was required as part of the EMCS submittal.

The Network-Configuration Submittal

The design went out to bid. A reputable control subcontractor representing an established EMCS product line was awarded the contract. When the submittal was received, the proposed network topology (Figure 2) raised a red flag concerning system reliability.

Note that in Figure 2, the EMCS equipment controllers and the VAV-box ASCs are connected in accordance with the configuration guide, while the chillers, boilers, and VFDs associated with each EMCS control panel are connected to the system on a single network originating at the main mechanical-room EMCS control panel. The contractor argued that the equipment network connections and the points they contained were few enough that they easily could be accommodated on a single MS/TP network. Further, the contractor noted that because of the high-speed Ethernet interpanel communications, there would be no measurable delay in executing commands to or receiving value or status data from the equipment. The equipment, the contractor contended, was "virtually" connected to the panel that controlled it.

Missing from the contractor's arguments was any consideration of system reliability. For example, imagine a building tenant, while independently reconfiguring its office network, inadvertently breaching the equipment network line. Some equipment may remain online, while other equipment fails. The breach and the affected equipment and systems could be on different floors. The building operations staff may not have been aware of the work taking place and, thus, have no idea of the location or cause of the failure. The problem could be very disruptive to system operation and difficult to troubleshoot.

Page 2 of 2

Resolving the Issue

The contractor configured the equipment network the way he did for several reasons. Most critical was that the EMCS control product could support only a single MS/TP "subnetwork" when the EMCS control panels were interconnected via Ethernet. Two solutions were considered:

- Add a second EMCS control panel—one for VAV-box support—for each air handler.

- Move the equipment network connection for each air handler to the VAV-box network.

Following discussions with the owner, the second, single-network solution (Figure 3) was chosen.

The change was anything but simple. An MS/TP network must be assigned a specific speed, with all of the devices connected to it set for the same speed. Some devices and equipment do not offer a full range of MS/TP speed, or baud rate. In this case, because equipment was being added to the network, a high baud rate was required for each air-handler subnetwork. This resulted in a lot of discussion and some pushback before the situation was resolved.

A Less-Than-Satisfactory Solution

Although the primary problem was resolved, the solution was far from ideal. Again, imagine a tenant reconfiguring its network causing an unexpected breach in one of the EMCS air-handler subnetworks between VAV boxes on one of the floors served by a VAV system. VAV-box controllers generally can operate without network communication for an extended period of time, giving operations staff time to track down and fix a problem. The same cannot be said of VFDs operating supply and return fans for air handlers; they need continuous communication with controllers to meet the changing airflow requirements of VAV boxes. In the example building, the VFDs are the first components on the subnetwork. Although, generally, only the equipment beyond a breach as described above will be affected, disruption of the entire network is not beyond the realm of possibility. It may be only a short time before VAV airflow does not match VAV-box requirements, and comfort or noise problems arise.

Especially in multitenant buildings, special consideration should be given to configuration to ensure the highest level of integrity and reliability of a network. In the example building, two subnetworks should have been required for the EMCS controllers serving air-handling units.

Integration With General Building Networks

Traditionally, EMCS network communication has been independent. Of great interest of late, however, is the integration of EMCS networks into wider building local-area networks (LANs). Managed switches can provide an EMCS its own broadcast domain, making the EMCS appear to have its own Ethernet and providing a strong element of security. Though separated, the EMCS shares bandwidth with all other traffic between switches and routers.

Generally, EMCS bandwidth requirements are insignificant compared with overall network system capacity and will have almost no impact on a LAN. The reverse, however, is not always true; if another system on the Ethernet is causing a bandwidth issue, an EMCS could suffer as a result. With a larger LAN, administration usually is superior because the smallest disruptions will be noticeable to a wide assortment of systems. With high-level IT support, the communication bandwidth will be upgraded continually to satisfy usage requirements. Should a LAN be maintained poorly, the advantages of integration easily could disappear or become disadvantages. With low-level IT support, network growth could overwhelm the infrastructure and impact an EMCS.

If, from an overall information-technology- (IT-) infrastructure standpoint, EMCS communication is determined to be more advantageous independent than integrated, the authors recommend it be specified by an IT specialist with independent switches/routers in selected data rooms. Although the switch/router equipment would have communication-fiber or Category 6 connections independent of other Ethernet systems, it would be maintained by the facility IT staff, receiving the same attention and residing in the same data closets as the other Ethernet systems.

Whether EMCS communication is independent or integrated into a buildingwide LAN, the building network infrastructure should be used. This places EMCS switches and routers in data rooms that are air-conditioned and backed up with uninterruptible power, and it ensures a high level of network-cable installation. This elevates the EMCS network to a professional system designed for network communication.

When considering integration, keep in mind that when you marry building IT and an EMCS network, you risk a completion-schedule conflict. The IT team may not plan to have the Ethernet backbone up and running until just before occupancy; however, the EMCS needs the network operational long before then for setup, programming, and checkout. This needs to be coordinated through specification of completion dates and vigilant construction management.

In the event a building's LAN is supported poorly, the traditional approach of having the EMCS Ethernet separate and installed by an EMCS contractor is recommended.

Conclusion

Employing networks and network connections in EMCS applications offers lower cost and more effective EMCS control and operations. Also, it contributes to expansion of EMCS capabilities in the future. To be successful in this endeavor, designers must carefully specify and manage the development of the network configuration. This means going beyond protocol specifications for network and device connection and:

Requiring any network-connected equipment controlled by the EMCS to be connected to a network originating at the panel containing the control for that equipment.

Ensuring device and equipment networks do not extend beyond the area(s) served by the devices. For example, a network connecting devices and equipment that are part of an air handler should not extend beyond the mechanical room in which the equipment is located.

Determining whether to share the building LAN or install a separate EMCS LAN based on the expected support of the building LAN and following up needed features in the specifications.

Network-based controls can advance the state of building operations. For a design to be successful, careful attention must be paid to the development of a sound configuration of networks.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].

Principal of The Hartman Co. (www.hartmanco.com), an HVAC engineering and technology-development firm, Thomas Hartman, PE, is an internationally recognized expert in the field of advanced high-performance building-operation strategies. His accomplishments include development of Hartman Loop, an integrated approach to chiller-plant control that dramatically improves operating efficiencies as plant load decreases; Terminal Regulated Air Volume, a network-based, variable-air-volume control technology that coordinates central-fan-airflow and supply-air-temperature control with actual zone requirements; the Dynamic Control family of software strategies and algorithms, which were among the first to employ integrated strategies to take advantage of microprocessor-based control systems; and the Hartman Energy Valuation System, one of the first hourly building-energy simulation programs. Senior engineer for The Hartman Co., Ron Anderson, PE, has more than 30 years of experience in the design, installation, and calibration of HVAC controls. Skilled in the programming languages of virtually all major systems, he has authored articles on controls and provided training on energy-management and control systems to maintenance staffs and building operators.