How would you answer the following multiple-choice question?

Which of the following are clean fuels?

- A. Hydrogen;

- B. Biomass;

- C. Iron;

- D. All of the above.

If you chose 'D', you are correct.

The first two – hydrogen and biomass – are obvious. And both have been frequently addressed in this column. But iron as a clean fuel is not so obvious. But metals, if ground into fine enough particles, can burn.

In the December 2015 issue of Applied Energy, J.M. Bergthorson and five colleagues in the mechanical engineering department at McGill University co-authored a paper entitled Direct Combustion of Recyclable Metal Fuels for Zero-Carbon Heat and Power. In it, the authors noted that hydrogen – although a clean fuel – was not “suitable for use as (an) international energy-trading commodity.” They also added that hydrogen could not, at the time, “provide the energy density and safety demanded by society.” The authors, which included a seventh contributor from the European Space Agency in The Netherlands, went on to propose:

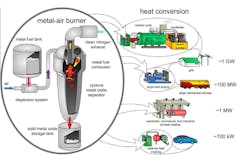

...a novel concept for power generation in which metal fuels are burned with air in a combustor to provide clean, high-grade heat. The metal-fuel combustion heat can be used directly for industrial or residential heating and can also power external-combustion engines, operating on the Rankine or Stirling cycles, or thermo-electric generators over a wide range of power levels,

Since that paper was published, several spin-offs from other universities have built demonstration plants using iron as fuel. In October 2020, a 100 kW iron-burning demonstration project, dubbed “Lighthouse Metal Power,” was built by the Metal Power Consortium – a venture of Eindhoven University and Metalot, a commercial spinoff from the university – at Dutch beer-maker Royal Swinkels Family Brewers. The iron fuel combustion provided heat for the brewing process.

- To download the new eBook, Ten Years of Clark's Remarks, click here.

The success of that effort subsequently led to the formation of a joint venture between Metalot, EMGroup, and Pompton known as IRON+. That spawned a letter-of-intent between IRON+ and the Royal Swinkels Family Brewers to build a 1 mW commercial plant to supply sustainable heat for its brewing process for the next 20 years.

Incidentally, this fall, Swinkels won the "Sustainable Brewery of the Year" award at the World Beer Awards competition. Montreal-based Altiro Energy, a McGill Innovation Fund cohort for which Prof. Bergthorson serves as chief technical advisor, also uses iron as an energy storage medium, that when burned can produce a large amount of clean heat.

This is all promising news. After all, according to the CRC Handbook of Chemistry and Physics, iron is abundant, making up 5.63% of the Earth’s crust. And iron’s energy density is higher than gasoline, 38.2 MJ/L vs. 34.2 MJ/L. So, iron as a clean fuel could, as Altiro Energy’s mission statement says, provide “a solution that can help eliminate carbon emissions on a global scale.”

Perhaps William Butler Yeats had it right in more ways than one, when he wrote a century or so ago, “Do not wait to strike till the iron is hot; but make it hot by striking.”

##########

A contributor to HPAC Engineering since 2013 and a member of its editorial advisory board, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. He can be reached at [email protected].