Asked to name the most important trait of a power plant—reliability, availability, or maintainability—most building owners and operators would say reliability. But is it really?

It is true that a power plant is a system of interdependent subsystems and that, if one of the subsystems fails, the entire power plant may be at risk of shutting down—a case for reliability being the most important trait. It also is true that most of the components in a power plant have parts that are rotating, reciprocating, or experiencing some type of stress cycle (thermal or mechanical), often under harsh conditions, and if the components are not monitored and maintained properly, they can fail quickly—a case for maintainability being the most important trait. However, it also is true that, most of the time, equipment must be shut down for maintenance to be performed. If a boiler is shut down for cleaning and inspection, it cannot generate steam. It may be extremely reliable, but it is unavailable the week it is shut down. With a power plant providing a utility typically required continuously, availability—the probability of functionality when required—is the most important trait of a power plant.

How can availability be maximized? A function of both reliability and maintainability, availability can be improved by maximizing uptime (reliability supplemented or enhanced by redundancy) and minimizing downtime (high maintainability).

Maximize uptime, minimize downtime—not unexpected advice. Still, it is much easier said than done. Let’s take a quick look at how this has been attempted over the years to see what does and does not work and why.

Types of Maintenance

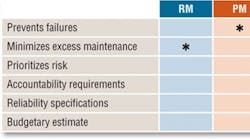

Reactive. Commonly referred to as “run to failure” (see “Running (Literally) to Failure,” HPAC Engineering, September 2010, http://bit.ly/Arnold_0910), reactive maintenance involves ignoring equipment until it fails. It is appropriate for inexpensive, non-critical pieces of equipment (e.g., light bulbs). The problem with it is that failures usually cannot be anticipated. Also, repair costs are higher because of the premium that must be paid for immediate response.

Preventive. Recommended in most equipment operation-and-maintenance manuals, preventive maintenance occurs on a schedule. Its basis is the concept that the likelihood of failure is proportional to the age or operating hours of equipment. The idea is that maintenance is better performed too often than not often enough. Changing the oil in a car falls into this category.

This form of maintenance has intrinsic cost ramifications that can be significant. More importantly, it has been shown to be ineffective in controlling failure rates, the reason being the probability of failure does not necessarily increase with age, and maintenance performed in excess increases the opportunity for human error and can shorten the life of parts.

Predictive/condition-based. During the 1980s, the concept of predictive, or condition-based, maintenance came about. The underlying concept of predictive maintenance is, “If it ain’t broke, don’t fix it.” Equipment is inspected routinely, with maintenance performed only as needed. The determining factor is a chosen indicator, such as a squealing belt on belt-driven equipment. Inspections are performed while equipment is operating so as not to affect availability. The idea is to maximize operation and avoid unnecessary maintenance.

The problem with predictive maintenance is that it is only as good as the indicator(s) chosen to determine whether maintenance is needed and the interval at which inspections are performed.

Reliability-centered. With predictive maintenance, power-plant operators with limited resources found they were wasting much time frequently checking insignificant items. This led to the development of reliability-centered maintenance, whereby maintenance tasks are prioritized according to risk using analytical methods, such as fault trees, or failure-modes-and-effects analysis.

Though it may seem new and cutting edge, reliability-centered maintenance has been around since the 1970s. It started as a government-funded initiative to improve military-aircraft and space missions. By the 1980s, it had proved successful enough that its scope was expanded to the Navy and nuclear industry. During the late 1990s, it was standardized by the Society of Automotive Engineers.1,2 In 2000, NASA published the first edition of “Reliability-Centered Maintenance Guide for Facilities and Collateral Equipment.”3

Despite a proven track record, reliability-centered maintenance has failed to gain widespread acceptance in the buildings industry, largely because of assumptions it is too complex and requires too much work. Where it easily can fail is where most great ideas fail: in the implementation. Experts estimate that as little as 5 percent of reliability-centered maintenance programs are implemented properly. Without the means for proper implementation, even the best-developed reliability-centered maintenance program can be just another (expensive) document sitting on a desk getting ignored.

Achieving Real Results

Reliability, availability, maintainability (RAM) is a concept with a history very similar to that of reliability-centered maintenance: Its origins are in the 1970s, and its intent was to assure availability for the military. Whereas reliability-centered maintenance was embraced more for aerospace, RAM primarily was the Department of Defense’s protocol for new and advanced combat equipment and weaponry. RAM concentrates more on the design and construction phases than reliability-centered maintenance. For that reason, it tends to be more of an all-encompassing, cradle-to-grave concept.

In 2009, ASME created a committee tasked with reviewing decades of research and documentation related to RAM and developing a standard for new and existing power plants.

The standard, the first draft of which is expected this year, focuses on three key priorities identified by power-plant owners: safety, production, and efficiency. Equipment has been assessed and a judgment as to risk or criticality made. To ensure availability, an appropriate level of reliability and/or redundancy is prescribed and the most appropriate maintenance program (reactive, preventive, predictive/condition-based, reliability-centered) given. Maintenance-program costs are estimated to aid budgeting. The standard can be customized to various facility sizes, risk levels, and budgets.

The standard requires assignment of a RAM manager, an individual who is responsible for the program’s teaching, implementation, and maintenance. A RAM program is a living document permitting continuous improvement and adaptation throughout a power plant’s life. This helps to prevent confusion, obsolescence, and, ultimately, disregard.

Conclusion

For those in the mission-critical industry, availability is a must. A proper maintenance and reliability program can be the difference between whether or not, say, a hospital stays open during a crisis. By utilizing RAM, operators of a critical-care or government facility that has had trouble keeping up with repairs or is plagued by unplanned outages may finally have a means of stabilizing maintenance and regaining control of availability.

References

1) SAE. (2009). Evaluation criteria for reliability-centered maintenance (RCM) processes. Warrendale, PA: SAE International.

2) SAE. (2011). A Guide to the reliability-centered maintenance (RCM) standard. Warrendale, PA: SAE International.

3) NASA. (2008). Reliability-centered maintenance guide for facilities and collateral equipment. Washington, DC: National Aeronautics and Space Administration. Available at http://www.wbdg.org/ccb/NASA/GUIDES/rcmguide.pdf

The leader of the power-plant-assessment-and-reliability team of RMF Engineering Inc., Brian Wodka, PE, CEM, LEED AP, has been performing power-plant assessments and boiler inspections for 12 years. He is a National Board of Boiler and Pressure Vessel Inspectors-commissioned boiler inspector; a licensed first-class stationary engineer in Maryland; the vice chair of the ASME committee tasked with developing standards related to the reliability, availability, and maintainability of equipment and systems in power plants; and a member of Maryland’s Board of Boiler Rules and Board of Stationary Engineers. He holds a bachelor’s degree in marine mechanical engineering from State University of New York Maritime College and a master’s degree in mechanical engineering from Johns Hopkins University.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].