Consulting engineers have a range of choices when it comes to high-thermal-efficiency boilers for commercial-building projects. For buildings with heating needs of 2 million, 3 million, or 4 million Btu, engineers often consider condensing boilers, which capture latent energy in flue gases that otherwise would be vented. Condensing boilers are especially appropriate when return-water temperature is below 113°F.

In specifying a condensing boiler, an engineer should be looking to meet or exceed the owner’s objective for energy savings not only for the near term, but over the decades-long life possible with today’s units. In doing so, he or she should examine operating conditions, product differences, installation and operational costs, and the like. This article will discuss those and other key considerations involved in the selection of high-mass condensing boilers.

Up-front Costs and Payback

Depending on the competition, today’s high-mass condensing boilers may come with a higher up-front cost than their low-mass counterparts; however, that higher purchase price is offset by greater efficiency gains and fuel savings over a longer service life. With an abundance of natural gas available from North American sources, fuel savings can be considerable, making payback less than one-sixth the duration of a boiler’s life.

For example, a high-mass condensing boiler may cost 10- to 20-percent more than a comparable non-high-mass boiler for an application requiring 6 million to 7 million Btu. A building requiring that kind of boiler-plant output capacity may have an annual expected fuel bill of $60,000. Factoring a conservative annual fuel-cost savings of around $2,000 yields a payback of $10,000 in five years’ time for the high-mass boiler.

Recovery Time

High-mass boilers often are thought to have slower recovery times because of their high water volume. A high-mass boiler, however, will maintain temperature in a vessel; as a result, heat-up time should not be an issue. Newer high-mass boilers experience minimal jacket loss because of up to 4 in. of factory-installed insulation (Photo A).

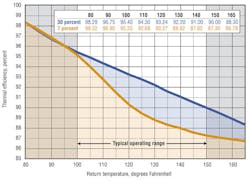

The combination of high water volume and large heat-transfer surface allows high-mass condensing boilers to adapt to changing system needs while maintaining optimum efficiency. This allows systems to be designed with higher delta-Ts and without the need for expensive dedicated boiler circulators. Design engineers should take care to ensure the parameters of their hydronic system match the corresponding efficiency of a boiler.

Figure 1 displays the most common range of return-water temperatures with associated efficiency values. Choosing a boiler that will operate at a high level of efficiency at system design requirements will maximize the project investment.

Design Advantages

Some high-mass boilers feature dual ports that prevent return water of differing temperatures from blending. This allows a lower return-water temperature and higher overall efficiency to be maintained.

Some low-mass boilers require decoupling from a system and use of a dedicated boiler pump matching minimum flow requirements. For example, with a 3-million-Btu boiler at a 20°F delta-T, water flow is 200 to 300 gpm. This requires a large dedicated pump. Additionally, 3- and 4-in. isolation valves are needed to allow service, maintenance, and replacement. Between the pump and valves, added costs could amount to $2,500. Engineers need to recognize these costs and a key difference between low-mass and high-mass: A high-mass boiler utilizes the main loop pump; a dedicated pump is not needed.

Maintenance Considerations

Condensing-boiler flue-gas condensate is corrosive by nature; as a result, boilers must be cleaned periodically. Boilers with very tight waterways and a lot of restriction require more frequent cleaning. The flue passages of high-mass boilers generally are wide open and capable of self-cleaning to a certain extent. Additionally, compared with their non-high-mass counterparts, high-mass boilers have a lot more surface to contain scale, and because comparatively little scale comes in contact with the heating surface, overall scale buildup is less.

Hybrid Configurations

High-mass boilers can be paired with conventional boilers for greater efficiency and lower first cost. For example, six high-mass condensing boilers and two conventional cast-iron boilers provide heating for a 32-story high-rise in Boston that achieved Platinum certification under the LEED green-building rating program. The high-mass boilers serve most of the load, while the conventional boilers supplement the hot-water loop during the coldest part of the heating season (Photo B). The developer, Boston Properties Inc., estimates the high-mass boilers will save over $16,000 in energy costs the first year alone.

Conclusion

Indeed, a non-high-mass boiler can be the best solution for a commercial building. Low-mass boilers in particular usually are less expensive and have a smaller footprint, making them better suited for retrofit applications, than high-mass boilers. But high-mass boilers are more efficient and save more on fuel and electricity costs. Design engineers should consider these factors in their choice of boiler type.

Mark Avron is national sales manager for Bosch Thermotechnology Corp. He has been active in the heating industry for 30 years, the last 17 with Buderus/Bosch. Johannes Mueller is floor-boiler and storage-tank product manager for Bosch Thermotechnology, which he joined in 2006. Prior to that, he was a project leader for high-efficiency wall-hung boilers in Wernau, Germany.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].