Study: Geothermal Heat Pumps Outperform VRF at ASHRAE Headquarters

In a two-year study of the geothermal-heat-pump (GHP) and variable-refrigerant-flow (VRF) heating and cooling systems installed at ASHRAE Headquarters in Atlanta, the GHP system outperformed the VRF system by a wide margin, the Geothermal Exchange Organization (GEO) says.

When ASHRAE contracted a major renovation of the two-story, 31,000-sq-ft building in 2008, it established a “living lab” for the evaluation of commercial-building energy and sustainability performance. In January 2013, GEO, with financial assistance from Southern Co., contracted a research team from Oklahoma State University and Oak Ridge National Laboratory to evaluate the relative performance of the VRF and GHP systems.

The VRF system serves spaces on the first floor, while the GHP system primarily serves spaces on the second floor. A dedicated outdoor-air system, meanwhile, supplies fresh air to both floors.

“Our study of heating and cooling performance at the ASHRAE building proves that over a two-year period—with all variables accounted for—energy use by the geothermal system averaged 44 percent less than the VRF system,” GEO President and Chief Executive Officer Doug Dougherty said.

The VRF system includes three dedicated split systems and two multizone inverter-driven heat-recovery units. The heat-recovery units are connected to 22 fan-coil units (FCUs). The cooling capacity of the heat-recovery units is 28 tons, while the three dedicated systems have an additional 10 tons of capacity. The GHP system includes 14 water-to-air heat pumps (two 3/4-ton units, six 2-ton units, and six 3-ton units) connected to a ground-loop heat exchanger consisting of 12 400-ft-deep vertical boreholes for a total of 31.5 tons of cooling capacity.

To facilitate efficiency studies, the building includes 1,600 sensors that monitor HVAC operations and conditions in each zone. Historical and current data from the sensors were available to the research team, led by Jeff Spitler, PhD, regents professor of mechanical engineering at Oklahoma State University. His colleagues included Xiaobing Liu, PhD, staff scientist at Oak Ridge National Laboratory, and Laura Southard, Oklahoma State mechanical-engineering graduate student. Southern Co. provided a power engineer to assist with on-site data measurements.

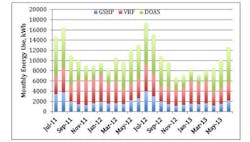

The researchers concentrated on determining actual heating and cooling provided by the GHP and VRF systems, data analysis, and computation of measured and experimental metrics. They collected two years of operational data (July 1, 2011, to June 30, 2013). Data points included operating mode (off/heat/cool), zone temperature, and discharge-air temperature for each FCU or heat pump. The researchers gathered data on ground-loop water supply, return temperature, and flow rate for the geothermal system.

The team also collected metered energy used by each system. For the GHP system, that included power for all 14 heat pumps, as well as the ground-loop water-circulation pumps. For the VRF system, power is metered and recorded only for the two heat-recovery units and the 22 FCUs connected to them. Power for the three dedicated split systems is metered through a different panel that also includes power used for computer servers and other equipment. All such differences were taken into account for comparison.

“Though the energy consumed by each system is affected by several factors, including floor space, heating and cooling loads, control strategies, and operating conditions/efficiencies, the efficiency implications of each system are clear,” Spitler said. “Raw data show that the VRF system used twice as much energy as the geothermal system during the two-year study period.”

The areas served by the GHP and VRF systems have different heating and cooling loads, so the research team estimated the loads provided by each based on individual unit airflows. Figure 2 shows that when differences in floor space were normalized, the energy use (kilowatt-hours per square foot) of the GHP system was an average 44 percent less than that of the VRF system.

“During the two-year study period, the GHP system used 29 percent less energy in the summer and 63 percent less energy in the winter/shoulder seasons than the VRF system while maintaining similar zone temperatures,” Spitler said.

“The underlying difference between the geothermal system and the air-source VRF system lays in the heat sink and source: ground vs. ambient air,” Spitler continued. “Though the control strategy for the VRF system resulted in longer runtimes compared to the geothermal system, it is clear that ground-loop water supply temperatures were more favorable than ambient-air temperatures for heat-pump operation. This allows the geothermal equipment to operate at higher efficiencies.”

“Final Report, Performance of the HVAC Systems at the ASHRAE Headquarters Building” is available at https://www.geoexchange.org/library/download-info/performance-hvac-systems-ashrae-headquarters-building/.

About the Author

Scott Arnold

Executive Editor

Described by a colleague as "a cyborg ... requir(ing) virtually no sleep, no time off, and bland nourishment that can be consumed while at his desk" who was sent "back from the future not to terminate anyone, but with the prime directive 'to edit dry technical copy' in order to save the world at a later date," Scott Arnold joined the editorial staff of HPAC Engineering in 1999. Prior to that, he worked as an editor for daily newspapers and a specialty-publications company. He has a bachelor's degree in journalism from Kent State University.