In late October 2012, Hurricane Sandy ravaged the eastern seaboard, causing widespread flooding, power outages, and tens of billions of dollars in damage. Following such a disaster, it is only natural for building owners and operators to want to get their mechanical systems and buildings back to full operation as quickly as possible. Early activation, however, may create substandard indoor-air quality (IAQ) that puts occupants and property at risk.

Water incursion does more than swamp buildings; it promotes environments that endanger sustainable business operations. An IAQ approach to remediation balances immediate business needs with longer-term environmental impact, helping to avoid mistakes that could worsen situations.

Immediately Following a Disaster

In the wake of a disaster, it is important to assess the situation. Specifically, determine:

• How the storm altered the surroundings, noting changed drainage patterns and damage to adjacent buildings that pose a threat to your facility.

• The amount of damage to the facility’s structural integrity, especially the roof, windows, doors, and walls.

• The extent to which evaporation increased moisture in wall cavities, above ceilings, and in other places where mold or microbial growth may occur.

• The degree of damage to electrical, mechanical, and control systems that were partially or completely submerged.

• Whether or not HVAC equipment was in operation at the time of the flooding. If any was, mold and other microbial contaminants may have entered the HVAC system, moving within air ducts and other areas that, at first glance, may not appear to have been impacted.

Restoring Healthy IAQ: Finding the Right Partners

Identifying individuals and firms knowledgeable about disaster-related indoor environmental issues starts with resources such as ASHRAE, the Indoor Air Quality Association, the American Conference of Governmental Industrial Hygienists, the American Industrial Hygiene Association, and the Institute of Inspection, Cleaning and Restoration Certification. These organizations have certified professionals to point you in the right direction.

Interview prospective engineering partners to gauge their experience with situations like yours, the outcomes of previous investigations, and the degree to which they meld engineering practices with building science, IAQ, and business priorities. Review past projects, and ask for a sample report to aid your understanding of the methods they use to determine plans of action.

Making Changes That Matter

The right engineering partner can suggest operational changes that impact the long-term performance and resiliency of a facility, changes such as:

• Maintain relative humidity between 30 and 35 percent. With relative humidity below 60 percent, mold growth is unlikely. Typically, relative humidity is maintained at 50 percent. Flooding, wind-driven rain, and other water intrusion can lead to a sudden increase in relative humidity. A relative-humidity setpoint of 30 to 35 percent provides a safety buffer against such an increase.

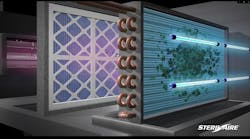

• Clean system components with HVAC-specific products that can be used safely while buildings are inhabited. Dirt, mold, and mildew are insulators that can reduce heat-transfer efficiency.

• Keep chiller leaving-water-temperature setpoints low. While raising chiller leaving-water temperature can save energy, it also can hinder the moisture-removal capability of cooling coils.

• Develop an air-management plan that discourages moisture migration and moves air from spaces that are clean to spaces that are less clean.

• Monitor indoor moisture levels to predict the possibility of future problems.

Preparing for Next Time

Having a disaster-response plan can help a facility resume operation more quickly. When developing a disaster-response plan, consider:

• Life safety. Develop a policy that identifies who makes the initial safety assessment, who has authority to approve re-entry, and how permission to re-enter the building is communicated to occupants.

• Environmental control. Make arrangements for temporary heating or cooling in advance, or it may not be available when needed. A moderate temperature results in better working conditions for repairpeople and helps to prevent problems from getting worse.

• Cleaning and repair. Arrange training for your staff, or pre-qualify contractors and/or consultants.

• The bringing online of equipment. Develop a way to quickly assess the condition of mechanical equipment and identify needed emergency and longer-term repairs. Of course, the sooner equipment is deemed fit to operate, the sooner it can be brought online.

Conclusion

A flood or other disaster can have many negative economic and operational impacts on a facility. It also can present opportunities for facility managers to effect long-term positive change.

The founder and general manager of BBJ Environmental Solutions, provider of cleaners, disinfectants, and controlling agents for HVAC and indoor-air-quality systems, Robert Baker, FASHRAE, has more than 30 years of clinical and practical experience in all facets of building operation and maintenance. He is a sought-after expert in the field of mold remediation.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].