Outdoor Air for Healthy and Energy-Efficient Indoor Aquatic Facilities

Operators of indoor aquatic facilities—be they at a major university, a local high school, or a community recreation center—face the challenge of providing a healthy environment while maintaining a low carbon footprint and minimizing operating costs. Fortunately, through thoughtful HVAC design, indoor aquatic spaces can be both healthy and energy-efficient.

To be healthy and durable, an indoor-pool space requires a well-designed air-distribution system with enough ventilation to exhaust toxic chloramines—pool-water-disinfectant byproducts—and protect the building structure and materials from harmful condensation and corrosion.

The energy intensiveness of indoor aquatic facilities comes primarily from:

- Air heating and cooling (sensible loads).

- Dehumidification (latent loads).

- Air distribution (fan-motor operating cost).

- Pool-water heating.

Air Heating and Cooling

When indoor aquatic facilities are occupied, air temperature usually ranges from 82°F to 86°F (28°C to 30°C). This means pool spaces are in heating mode for much more of the year than other indoor environments.

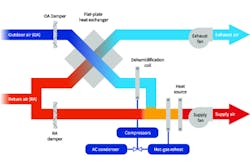

Transferring heat from exhaust air to entering outdoor air can significantly reduce outdoor-air sensible load. This can be accomplished using a heat pipe or run-around coil (both with efficiency ratings of 45 percent to 55 percent) or using a flat-plate heat exchanger (65 percent to 75 percent efficiency) (Figure 1).

FIGURE 1. Exhaust-air energy recovery reduces entering-outdoor-air sensible load. Using an air-to-air heat exchanger, which transfers heat from the exhaust-air stream to the entering-outdoor-air stream, can significantly reduce energy costs. Energy efficiency varies from 45 percent to 55 percent for run-around coils and heat pipes to 65 percent to 75 percent for flat-plate heat exchangers.

Pool-water evaporation is the largest component of space latent load and pool-water heating load. It can be controlled by:

- Keeping air temperature 2°F (1.1°C) above water temperature. Pool operators often choose to lower space temperature or raise water temperature in an attempt to reduce energy costs or increase comfort. This, however, tends to have the opposite effect. It greatly increases evaporation rate and total energy costs and causes swimmers exiting the pool to feel cold.

- Controlling space relative humidity (RH) to 60 percent, when possible (unless the amount of fresh air supplied for chloramine control causes the humidity to go below 60 percent). Evaporation increases 30 percent for every 10-percent drop in pool space relative humidity.

Chloramines

Most swimming pools are treated with chlorine. When chlorine binds to water contaminants, it forms chemicals such as dichloramine and trichloramine. These chloramines irritate the skin and eyes and off-gas into the air, where they are toxic to breathe and corrosive to building materials.

“Chloramines can build up in the water, which means they can build up in the air if there is not enough fresh air surrounding pools and other places people swim in chlorinated water,” the Centers for Disease Control and Prevention says,1 citing a Health Hazard Evaluation report.2 “This is particularly true for indoor aquatic facilities where air handling systems are not bringing in enough fresh air and exhausting enough chloramine-polluted air, which is common during winter months when heating costs increase. Chloramines that off gas from the water are heavier than air. This means they settle on top of the water’s surface where they can cause negative health effects in swimmers and spectators.”

When chloramines concentrate above the water surface, maintaining proper water chemistry can be a challenge. Additionally, chloramine-polluted air is acidic and corrodes stainless and carbon steel, which can cause structural deterioration.

A healthy and durable pool environment requires a ventilation system providing proper air distribution and enough circulating outdoor air to exhaust chloramines.

Dehumidification

The choice of dehumidification technology has a major effect on energy usage. Three strategies commonly used to dehumidify air are:

- Chemical dehumidification. Chemical dehumidification systems utilize desiccants and typically require post-cooling. At the high dew points of pool spaces, they generally are not economical. Additionally, desiccants deteriorate when exposed to chlorine.

- Mechanical dehumidification. Mechanical dehumidification systems use cooling coils, typically with reheat, to extract moisture from indoor air. Complex options include multiple condensers and pumped-glycol overlays for recapturing energy from compressor operation.

- Outdoor-air dehumidification. Outdoor-air dehumidification systems replace moist indoor air with dry outdoor air. In most climates, systems using only unconditioned outdoor air cannot provide humidity control on humid summer days. When unconditioned outdoor air alone cannot meet a dehumidification load economically, mechanical dehumidification—often, a cooling coil with reheat—can be used to treat outdoor air. Utilizing higher amounts of outdoor air can provide a margin of safety in the event of problems with pool-chemistry control.

Introducing low-humidity outdoor air—even when that air needs to be heated—can be the most economical way to dehumidify indoor aquatic facilities, especially because fresh air already is being delivered to dilute indoor-air contaminants.

Savings

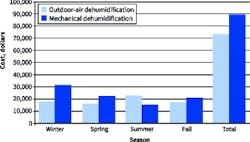

With a 6,300-sq-ft competition pool in a 300,000-cu-ft facility maintained at 82°F (28°C) and 60 percent RH, the following operational-cost reductions can be had when using hybrid outdoor-air dehumidification for most of the year, as opposed to mechanical dehumidification year-round:

- Atlanta (ASHRAE Climate Zone 3): 20 percent (Figure 2).

- Dallas (ASHRAE Climate Zone 3): 15 percent.

- Los Angeles (ASHRAE Climate Zone 3): 25 percent.

- Washington, D.C., and Kansas City, Mo. (ASHRAE Climate Zone 4): 30 percent.

- Minneapolis; Portland, Ore.; and Boston (ASHRAE climate zones 4, 5, and 6, respectively): 40 percent.

- Denver (ASHRAE Climate Zone 7): 50 percent.

FIGURE 2. Total operating costs, including costs for air heating, pool-water heating, dehumidification, and fan motors, for an indoor aquatic facility in Atlanta.

(Note: Outdoor air is not a substitute for proper water treatment. A healthy pool requires an effective water-treatment system.)

Air Distribution

Proper air distribution in an indoor aquatic facility:

- Prevents condensation.

- Prevents corrosion.

- Prevents temperature and humidity stratification.

- Removes airborne disinfectant byproducts, such as chloramines.

- Provides effective mixing throughout the space.

- Delivers fresh outdoor air to swimmers’ breathing zone (just above the water surface), to people on the deck, and to spectators.

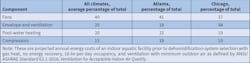

A high rate of total air movement is needed for all of this. As shown in Table 1, fan-motor costs often are the largest component of energy usage. Because of the complex air-distribution requirements, variable-air-volume control strategies for reducing fan costs should not be applied during occupied operation. Whether or not a space is occupied, the air-distribution system must continuously prevent condensation, corrosion, and stratification, which requires that diffusers throw air effectively.3

TABLE 1. Component energy costs for an indoor aquatic facility maintained at 82°F and 60 percent RH.

A typical indoor-pool space has several microzones, including the swimming area, the deck, and spectator areas, requiring condensation and corrosion prevention. Pool spaces often are quite tall (from 15 ft to 50 ft [4.5 m to 15.2 m]) and require good mixing throughout to prevent stratification and dead spots that can lead to corrosion. This can necessitate a higher amount of outdoor air in the total supply-air rate.3

Supply air to the breathing zone over a pool and up to 72 in. above the deck. Supply air must be directed toward a pool’s surface to move chloramines from the swimmers’ breathing zone toward deck and spectator areas (if those areas are not served by a separate unit) and toward lower-level exterior-facing walls and windows to prevent condensation and corrosion. Use of a common supply duct with directed nozzles or diffusers for lower-level supply requirements (air to the pool surface, air to the deck breathing zone, and lower-level condensation prevention) may be possible.

Supply air to exterior glass and walls, the roof, and elevated spectator areas. Supply air directed at exterior wall and roof surfaces must be sufficient enough to prevent condensation, especially on glass surfaces. During winter, the dry outdoor air introduced to improve indoor-air quality (IAQ) forces the relative humidity down, which helps to prevent condensation. If a spectator area is located within a pool space, the design minimum-outdoor-air amount for a swim meet must be delivered.4

Depending on the amount of supply air needed for spectator areas and enclosure condensation/corrosion prevention above the breathing zone, the ratio of percentage of air delivered high in a space to that delivered low may vary from 30-70 for a lower-height facility with few windows to 60-40 for a tall facility with a large spectator space and significant potential for condensation on exterior surfaces.

Delivery of air to spectators and to upper-level areas requiring condensation and corrosion prevention may be possible with a common supply duct with properly sized and directed nozzles or diffusers.

Location of return-air inlets. A combination of low and high return-air grilles promotes chloramine removal and good mixing throughout a space and prevents stratification and corrosion. At the low return level, there are three common configurations for removing chloramines that concentrate over a pool:

- Low-level deck return, with one or more grilles located a few feet above deck level. Lower-level return air mixes with upper-level return air prior to entering the air-handling unit.

- Low-level deck exhaust, with one or more grilles located a few feet above the deck and connected to a dedicated exhaust duct to avoid exhaust air mixing with return air.

- Source capture, a system with multiple exhaust points in the water-level pool gutter that are manifolded into one exhaust duct.

These low-return configurations often can be incorporated into a pool air handler. At the high return level, return points should be located to mix air supplied to spectator areas and air supplied to the upper level to prevent condensation and corrosion. Care must be taken to avoid locating return points immediately adjacent to supply diffusers to prevent short-circuiting of supply air.

Ventilating and Dehumidifying With Outdoor Air

A real-world example of the IAQ and energy benefits of optimization of outdoor-air use is the Burdick Hall natatorium on the campus of Towson University in Towson, Md.5 Swimmers there long had complained of respiratory problems, especially an ailment known as “swimmer’s cough.” The swim coach knew the source was the buildup of chloramine gas above the water surface. The associate director of engineering for the university’s facilities-management department sought to improve the natatorium’s IAQ in the most energy-efficient and sustainable manner possible. The design team chose to use higher amounts of outdoor air for ventilation and dehumidification. This method, coupled with the use of flat-plate heat exchangers to recover energy from return air, was the most energy-efficient option.

Increasing outdoor air improved indoor-air quality and reduced energy costs in the Burdick Hall natatorium at Towson University.

The facility engineering director said the difference between the pre-renovation pool environment and the post-renovation pool environment was like that between night and day. What’s more, feedback from the swim coach was exceedingly positive.

Summary

Indoor aquatic facilities can be both healthy and energy-efficient. Intelligent use of outdoor air has two main benefits. First, it flushes toxic chloramines from a space, making it healthy for swimmers and spectators. Second, outdoor air is dryer than pool air for most of the year and becomes a natural and efficient way to dehumidify indoor-pool spaces with high latent loads. Only during summer when outdoor dew points are high is there a need for more expensive mechanical dehumidification. During winter, efficient exhaust-air heat recovery warms entering outdoor air, reducing operating costs.

A design employing outdoor air for dehumidification coupled with simple and efficient energy recovery, thoughtful choice of space conditions and water temperature, effective air distribution, energy-efficient enclosure design, and enough outdoor air to ensure healthy IAQ will lead to a cost- and energy-efficient indoor aquatic facility.

References

- CDC. (n.d.). Chloramines & pool operation. Retrieved from https://www.cdc.gov/healthywater/swimming/aquatics-professionals/chloramines.html

- Chen, L., et al. (2008). Investigation of employee symptoms at an indoor waterpark. HETA No. 2007-0163-3062. Available at https://www.cdc.gov/nceh/ehs/Docs/Investigation_of_Employee_Symptoms_at_an_Indoor_Waterpark.pdf

- Lochner, G. (2017). Special operating modes. Available at https://tinyurl.com/pools-special-modes

- Lochner, G. (2016). Ventilation and air distribution in indoor aquatic facilities. Available at https://tinyurl.com/pools-ventilation

- Innovent. (2010, August). Natatorium dehumidification units improve IAQ, boost energy efficiency. HPAC Engineering, pp. 22-23. Available at http://bit.ly/Innovent_0810

The vice president of applications engineering for Unison Comfort Technologies, Gary Lochner has participated in the design of more than 1,000 HVAC units serving indoor aquatic facilities ranging from high-school pools to community recreation centers to major water parks over the last nearly 25 years and has spoken on design considerations for these spaces at many ASHRAE chapter meetings. He holds a degree in mechanical engineering with an emphasis in heat transfer from the University of Minnesota. As strategic marketing director for Unison Comfort Technologies, Randy Amborn draws upon over 30 years of HVAC experience to provide marketing and communications leadership for the three brands under the Unison umbrella: Innovent Air Handling Equipment, Valent Air Management Systems, and Precision Coils. He has authored numerous articles on building-system issues and trends for industry publications. He holds a bachelor’s degree from the University of Minnesota with an emphasis in technical communication and computer science.

About the Author

GARY LOCHNER

Vice President of Applications Engineering

The vice president of applications engineering for Unison Comfort Technologies, Gary Lochner has participated in the design of more than 1,000 HVAC units serving indoor aquatic facilities ranging from high-school pools to community recreation centers to major water parks over the last nearly 25 years and has spoken on design considerations for these spaces at many ASHRAE chapter meetings. He holds a degree in mechanical engineering with an emphasis in heat transfer from the University of Minnesota.

RANDY AMBORN

Strategic Marketing Director

As strategic marketing director for Unison Comfort Technologies, Randy Amborn draws upon over 30 years of HVAC experience to provide marketing and communications leadership for the three brands under the Unison umbrella: Innovent Air Handling Equipment, Valent Air Management Systems, and Precision Coils. He has authored numerous articles on building-system issues and trends for industry publications. He holds a bachelor’s degree from the University of Minnesota with an emphasis in technical communication and computer science.