Ensuring Proper Fan-Belt Tension

A properly tensioned belt ensures smooth operation and extends the service life of fans and motors. Conversely, an improperly tensioned belt can cause a host of easily preventable problems, including noise, vibration, poor fan performance, bearing wear, and shortened fan-motor life.

This article discusses several methods of measuring the tension of V-belts commonly used in HVAC applications. Belt tensioning often is done during initial startup and then periodically during preventive-maintenance calls. Common methods of measuring belt tension are by deflection, frequency, and the use of a tension-finding device. While there are a number of manufacturers of belt-tensioning equipment, the following discussion and steps are based on Carlisle products.

Understanding Proper Belt Tension

The proper tension of a V-belt drive is the lowest tension at which the belt will not slip at peak-load conditions. For applications without a variable-frequency drive (VFD) or starter, a belt must be tensioned to handle increased motor torque during startup. For slow-start VFD applications, a belt must be tensioned to handle the actual brake horsepower of the fan at the fan shaft.

After initial installation tensioning, retensioning of a V-belt is recommended after one to two days. After that, belt tension should be checked periodically—about every three to six months or more frequently, if noise or vibration occur.

Undertensioned belts can slip, generating heat that results in cracking and eventual belt failure. Overtensioned belts stretch excessively, which reduces belt and bearing life, as bearing loads increase. While checking belt tension, one also should inspect for cracks or fraying, as these indicate belt wear.

Measuring Belt Tension by Deflection

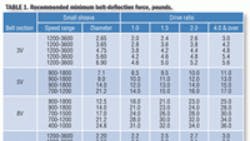

By measuring the force required to deflect a belt at a given distance, one is able to evaluate belt tension. Recommended force for proper belt tension can be referenced in Table 1. This information is based on readings achieved using a tool that Carlisle calls a tensiometer. This article provides instructions for a single-stem tensiometer. A tensiometer measures the force required to deflect a belt at a given distance. This force can be compared to a table of recommended tension forces to determine the status of a belt.

The equipment needed to measure belt tension by deflection are a tensiometer, tape measure, and straight edge (for single-belt drives). Follow this procedure:

1. Turn off power to the motor and follow lockout and tagout procedures.

2. Measure the span length of the belt (Figure 1). Span length is the distance between the sheaves. The desired belt deflection is 1/64 in. for every 1 in. of belt span. For example, if the span length is 32 in., the desired belt deflection is ½ in.

3. Set the large O-ring on the tensiometer to the desired deflection determined in Step 2 (Figure 2).

4. Set the small O-ring on the tensiometer to the zero mark (Figure 2).

5. Hold the tensiometer as indicated in Figure 2, and press the opposing end of the tensiometer to the midpoint of the belt span, as indicated in Figure 1. Press down on the tensiometer (deflecting the belt) until the large O-ring is even with the original location of the belt. For a single-belt drive, the tensiometer should be depressed until the large O-ring is lined up with the bottom of the straight edge placed on the outside rims of the two sheaves. For a multiple-belt drive, depress the tensiometer until the large O-ring is even with the top of the next belt.

6. Read the small O-ring, which now indicates the force (in pounds) required to attain the desired belt deflection. Check this reading against the recommended minimum belt-deflection force in Table 1. For a multiple-belt drive, take a reading from each belt for an average.

7. Tighten or loosen the belt to achieve the recommended minimum belt-deflection force. Tightening the belt will increase belt-deflection force; loosening the belt will decrease it.

Measuring Belt Tension by Frequency

The natural frequency of a tensioned belt can be used to calculate the tension of the belt. This method is applicable for V- and banded belts.

One way to measure the natural frequency of a belt is by using a frequency-finding device (Figure 3). Carlisle's Frequency Finder uses a laser sensor to measure the frequency of a vibrating belt. This frequency then can be compared to the recommended frequency calculated with the software that accompanies the instrument. To measure belt tension by frequency:

1. Turn off power to the motor and follow lockout and tagout procedures.

2. Use Frequency Finder's software to calculate the desired minimum and maximum frequency for the belt. The frequency directly correlates with belt tension. The higher the frequency, the greater the belt tension.

3. Turn on Frequency Finder. The laser light will turn on.

4. Tap or pluck the free belt span to induce vibration in the belt.

5. Hold the laser probe no more than 1 in. off the free belt span, with the laser facing the outside of the belt.

6. Check the frequency being displayed (in hertz) on Frequency Finder.

7. Compare the reading from Step 6 to the desired range determined in Step 2. If the reading is below the desired frequency range, tighten the belt. If the reading is above the desired range, loosen the belt.

Using Tension Finder

Tension Finder is a gauge used to measure the amount of stretch in a tensioned belt. Tension Finder should not be used with aramid or glass-cord belts, as it could result in damage to the equipment.

To measure belt tension using Tension Finder:

1. Turn off the power to the motor and follow lockout and tagout procedures.

2. Install the belt loosely on the aligned sheaves.

3. Increase the center distance of the sheaves to apply enough tension to the belts to remove slack.

4. Using a pen or marker, scribe a line on the belt perpendicular to the direction of travel.

5. Place the start slot of the Tension Finder device over the line scribed in Step 4.

6. Attach the spring to the belt with the scribed line still in the start slot of Tension Finder. For reference, if the spring slips, scribe a line on the belt at the spring end of Tension Finder.

7. Determine the required tensioned slot for belt line and belt use by using Table 2.

8. Tension the belt until the scribe line from Step 4 is displayed in the designated slot of Tension Finder, as determined in Step 7 (Figure 4).

9. Remove the Tension Finder device from the belt before operation.

Brian Mleziva is an application engineer for centrifugal, vane-axial, and industrial products for Greenheck Fan Corp. His responsibilities include product development, marketing-support materials, and customer service. He has a degree in mechanical engineering from Michigan Technological University.

VIDEO DEMO

For an HPAC Engineering-produced video demonstration of HVAC-belt tensioning, go to http://bit.ly/Optibelt_video.