Tall-Building Riser Design

Copper Development Association Inc. (CDA) would like to respond with pertinent information to supplement the article in the October 2016 edition of HPAC Engineering titled “Dynamics of Tall-Building Riser Design, Part 1 of 2” by Marty Rogin, PE.

Mr. Rogin states in the article: “Whether this type of system can be adapted to copper risers is unclear. Available manufacturers’ literature does not specifically mention copper as an acceptable pipe material for these support systems.”

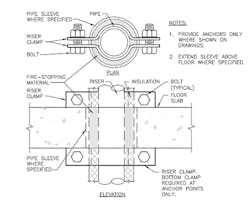

Copper and copper-alloy piping materials have been utilized in thousands of multistory vertical-riser installations and provided excellent and sustainable performance. CDA provides data related to the calculation of expected expansion and contraction of copper tube at higher temperatures, as well as suggested support for copper tube passing through concrete floors, in Section 3 of its Copper Tube Handbook. A detail of stack supporting is shown in the accompanying figure.

In Mr. Rogin’s example of a 50-story building with a 500-ft riser with a 130°F delta-T, the following would be the expected overall expansion of the 500-ft length of copper tube. Using the standard equation for pipe expansion, the same as noted by Mr. Rogin, the copper riser would be expected to expand 7.332 in. over the entire 500 ft:

∆L = (coefficient of expansion for copper) LO ∆T

∆L = (9.410-6) (500 ft or 6,000 in.) (130)

∆L = 7.332 in.

Using Mr. Rogin’s example of the floor-to-floor dimension being 10 ft, copper tube would be expected to expand 0.147 in., or slightly over 1/8 in. Supporting the stack at each floor level, as shown in the accompanying figure, would limit tube movement between floors, reducing strain at any horizontal branch connections.

Respectfully submitted,

Copper Development Association Inc.

Author’s response:

I agree with the comments in the CDA’s response to my article. I have seen several successful copper-riser installations, and I am familiar with the figure accompanying the letter. Many of the riser projects sent to Metraflex involve replacements of steel risers with copper. Also, I routinely turn to the Copper Tube Handbook for information on anything related to copper tube; it is a great resource.

My intent with the referenced passage was not to imply copper is not suitable for risers. I simply was unable to find a manufacturer of a spring-riser support system for copper. It looks like there are a few for steel risers.

Marty Rogin, PE

The Metraflex Co.

Chicago, Ill.

Being an Automation- and Control-Systems Integrator

“So, You Want to Be a ... Automation- and Control-Systems Integrator” by Steve Joanis (November 2016) is a great article. It reads like good fatherly advice with efficiency in words. It draws a picture of the glory of the position and at the same time clearly spells out what is required to fill those big shoes.

I started in the control industry working for an independent controls contractor in 1962. The gentleman who owned the company would accept nothing short of perfection. What a great learning opportunity to immerse in the technology and its ramifications plus an appreciation of the responsibilities.

I am now semi-retired and teaching part-time at night at a local community college to give back to the industry in appreciation for all those generous people who have given to me along the way. I will be sure to present this article to my students.

Jean F. Haydel

Haydel Associates LLC

River Ridge, La.