As had become ritual for the two longtime friends, Fred and William were taking time from their busy schedules as engineers to enjoy lunch together at their favorite restaurant. Fred, a mechanical engineer, especially looked forward to these weekly get-togethers, as they provided an opportunity for him to discuss the vagaries of HVAC design, whatever challenge was confronting him on his latest project, and the oftentimes unconventional solution he was considering. In William he had not only a receptive audience, but a unique sounding board—as a civil engineer, William offered a perspective unlike that of Fred’s office mates; rare was the occasion he was unable, by means of an observation or a question, to spark an idea that caused Fred to look at his project in a new light. Today, unfortunately, was one of those occasions.

“I’m sorry I can’t be of more help,” William said, “but I think I know someone who could be. His name is Sam. He’s a retired consulting engineer—70 years old, but still sharp as a tack. He’s a friend of my dad’s. After Sam’s wife died a few years ago, his children talked him into assisted living; his facility’s not far from here. He was forced into retirement because of his age—sadly, not long after his wife passed—so I know he misses engineering work. He doesn’t get a lot of visitors, so I think your calling on him would be beneficial to you both. Are you interested?”

Before Fred could answer, William added: “One thing you should know: Sam is from the old school. If you meet with him, make sure you take a calculator, a pad of paper, and some pencils and erasers. Don’t try to use a calculator app on your phone or a sketching app on your tablet; he may just send you away. If you can get him to talk to you, I think he can help.”

Fred smiled. “Set it up,” he said.

-------------------------------------------------

Two days later, Fred, a legal pad, two mechanical pencils, a Pink Pearl eraser, and a scientific calculator in hand, was in the waiting area of the assisted-living facility Sam called home. A smiling nurse named Julie approached him.

“You can go in and see him now,” Nurse Julie said. “It is lunchtime. He seems to eat better when he has company. Please get him to eat some.”

Nurse Julie led Fred to the dining room and Sam’s table. Sam eyed Fred over his coffee cup.

“What brings you here, young man?” Sam asked.

“I am hoping you might be able to help me with a chilled-water problem I’m having,” Fred replied.

Sam lowered his coffee cup and sat up slightly in his chair.

“Did you bring anything to work with?” Sam asked.

Fred produced the legal pad, pencils, eraser, and calculator.

“Sketch your problem as you tell me about it,” Sam directed.

“It is a hospital chilled-water system that has been around for several years, with three equal-sized chillers that recently were replaced,” Fred explained. “As part of the commissioning of the new chillers, it was noticed the return-water temperature was coming back lower than designed.”

“Ah, low-delta-T syndrome,” Sam said before taking a bite of his turkey sandwich. “What did you do?”

“We have been through existing air-handling units and fan-coil units, cleaning coils—both air and water side—and recommissioning controls,” Fred said. “We found and fixed some issues, but that didn’t help much. The air-handling units serving the surgery suite and the air-handling units serving the ICU are now making colder air than they were originally designed to do: 52°F instead of the original 55°F. We ran models of the coils, and they showed that making colder air with those coils actually reduced the chilled-water-return temperatures because we had to increase the flow by so much.”1

Sam snorted and took a big swig of coffee.

“You don’t need a big computer model for that,” Sam said. “Look up log mean temperature difference in one of your old textbooks and see what needs to happen as you vary one of the temperatures with a fixed heat exchanger. This system sounds old enough to be primary-secondary. Am I right?”

“Yes,” Fred replied.

“What are you trying to accomplish?” Sam asked.

“The owner is not happy with the operation of the new system,” Fred said. “A second chiller, pumps, and tower have to start up before the first chiller is fully loaded. I can see that replacing coils in the air-handling units could raise the return-water temperature back up, but that is a very expensive process with a lot of downtime in critical areas of the hospital. We also want to save energy by having warmer water flow back to the chillers. Operating efficiency of the chillers is also important to this owner.”

Just then, a smiling Nurse Julie came by with slices of apple pie for both Sam and Fred.

Sam took a bite. “Let me see your sketch,” he said.

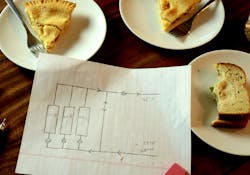

Fred handed his legal pad (Figure 1) across the table.

Sam adjusted his bifocals. “Is there a check valve in this bypass line?” he asked.

“No,” Fred replied. “We do not need one because, if the secondary chilled-water-supply temperature gets above setpoint, we start another chiller.”

“Do you have a lot of three-way valves in the system?” Sam asked.

“No,” Fred said. “Just enough to maintain the manufacturer’s recommended minimum flow through the secondary pumps.”

“How are cooling towers piped and controlled?” Sam asked.

“There is a separate tower for each chiller, with a VFD on tower fans for condenser-water-temperature control,” Fred replied. “The tower water pumps are constant-speed.”

“Do they run year-round chilled water?” Sam asked.

“Yes,” Fred said. “They have a small air-cooled chiller for surgery and the ICU, but many of the areas, like MRI and CT, have DX cooling equipment that came with the medical equipment.”

Sam put aside his fork. “That was some good pie,” he said. “There is at least one thing I can think of that you can do to run one chiller longer without having to replace any coils. See if you can work it out before you come back.”

“Come back?” Fred said, a bit surprised.

Sam already was moving back to his room.

“It will be a few days before I can get back here,” Fred said.

Without turning around or even breaking stride, Sam replied with a wave of his hand: “That’s OK. I should still be here. I don’t go much of anywhere these days.”

-------------------------------------------------

A week later, as Sam sat picking at his lunch and gazing out the window, Fred entered the dining room. Sam immediately brightened.

“So, young man, have you figured out how to run one chiller longer without replacing any coils?” Sam asked.

“I went back and forth looking at many things,” Fred said. “The load and the coils don’t change, and we can’t raise the supply-water temperature, so something at the plant has to change.”

“Good,” Sam said. “Go on.”

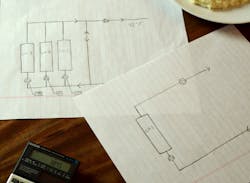

Fred pulled out his sketch from the previous week and began adding to it (Figure 2).

“Well, we can put a VFD on the primary pump for the chiller, open the balancing valve fully, and increase the flow through the chiller slightly, but that will not get us much,” Fred said. “The pressure drop through the chiller goes up with the square of the flow. We would have to replace the pump motor or even the pump to get enough to make a big difference in when we have to start the next chiller.”

Taking a bite of mashed potatoes, Sam said, “Sketch your bypass again, and show one chiller with it.”

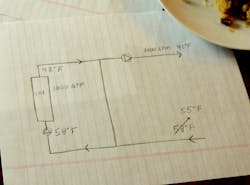

Fred complied (Figure 3).

“It’s all about the load,” Sam said. “Let’s say your chiller can cool 1,000 gpm from 58°F to 42°F. On the pipe going out to the system, write 1,000 gpm and 42°F, and on the pipe coming back from the system, write 58°F (Figure 4). So, if the temperature coming back is 55°F and the flow is 1,000 gpm, do we have to start another chiller?”

“No,” Fred answered. “We only have a problem when the flow gets over 1,000 gpm. Otherwise, the supply-water temperature is still controlled at 42°F with one chiller.”

“So,” Sam said, “looking at just tons and 42°F out and 55°F back, what would the gallons per minute be where the tons consumed by the system would match the tons capacity of the one chiller?”

That was pretty straightforward.

“One thousand two hundred thirty gallons per minute,” Fred said, looking up from his calculator and legal pad, “and at that point, we will have 230 gpm of 55°F water coming from the return to the supply water, and we will not be able to maintain our supply-water temperature out to the system. We have to maintain that supply-water temperature, or surgery and the ICU will get too hot.”

“Whoa, slow down,” Sam scolded. “Look at the tee where the bypass meets the water coming out of the chiller. What could you do to get 42°F water out to the system?”

Sam went back to his mashed potatoes, but watched Fred closely.

Fred stared at the tee for a bit. “I suppose we could drop the temperature coming out of the chiller,” he said.

“What temperature would you need coming out of the chiller for the mixture to be 42°F?” Sam asked.

Fred went back to his paper and calculator. “Thirty-nine degrees,” he said, “but our chiller was only designed to put out 42°F.”

“It was designed for a 16-degree delta-T, and now it has 55°F water coming into it,” Sam explained. “It seems like it should come pretty close to a 39-degree discharge.”

Fred was thinking that just might work. “So, we reset the chiller discharge temperature to maintain the 42°F supply-water temperature?” he asked.

“Yes,” Sam replied. “What if you get 1,250 gpm of 55°F water back?”

Fred did more calculating, stopped, and smiled. “We would have to get 38.75°F out, but we can’t because, by the temperatures and flow, the actual load is more than one chiller can handle. So, we will have to start another chiller.”

Sam smiled. “Good job,” he said. “Nurse Julie has carrot cake for us today.”

As the two men finished their cake, Fred said: “It’s too bad we can’t get warmer water back from the system to increase the efficiency of the chiller at part load. With a properly sized coil, we will get warmer return water at part loads, and we would get better efficiency.”

“Bah,” Sam said. “If the load from the system is 50 percent, the return water to the chiller for the system we have been playing with will be 50°F no matter what the temperature coming back from the building is. Come back when you can tell me why that is true, and I will tell you a good way to save some energy on your system.”

-------------------------------------------------

A few weeks later, Fred was back.

“I thought you would like a treat,” Fred said, placing a box of cookies on the dining-room table.

“Snickerdoodle, one of my favorites,” Sam said, smiling. He put the cookies to the side to enjoy after lunch.

“I’m ashamed to say I did several rounds of calculating temperatures and flows before I finally figured out what you were talking about the last time we met,” Fred said. “Since the primary flow in a primary-secondary system is constant, the only variable on the primary side when the load changes is the return-water temperature to the chiller. It doesn’t matter how warm the return-water temperature gets; as long as the load is only 50 percent of the design load on the chiller, water will come back through the bypass and mix with the return water to get to 50-percent delta-T.”

“Exactly,” Sam said between bites of meatloaf. “Now, how can you use that knowledge to save energy at the chiller?”

“I will need to change the flow through the chiller to keep the return water as warm as possible,” Fred said, “but the controls for that seem to be difficult. Let me show you what I mean.”

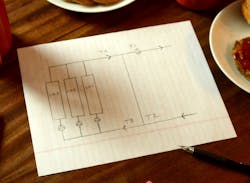

With that, Fred sketched the chillers and bypass again (Figure 5). “T1 is the temperature of the water going out to the system on the secondary side, T2 is the temperature of the water coming back from the loads on the secondary side, T3 is the temperature of the return water going to the chillers on the primary side, and T4 is the temperature of the supply water coming out of the chillers,” he said. “We want the warmest temperature we can get going into the chillers, so we want T3 to equal T2. At the same time, we must have the right-temperature water going out to the secondary loop, so T1 should equal T4. The sensors we normally use have an accuracy of only ±0.5°F. Trying to control to both of those requirements at once is just asking for a lot of hunting of the controls that will only cause problems.”

Sam nodded while spreading butter on his dinner roll. “You do a good job of stating the problem,” he said. “Now, which part is most important to you?”

After some thought, Fred replied, “Controlling the secondary supply-water temperature is more important than saving the most energy we can.”

“So,” Sam said, “how about if you control the chiller-VFD speed to maintain the temperature at T3 about 1°F below T2?”

“That should work,” Fred said. “Because we’re changing the flow, we can’t change the chiller discharge temperature at the same time, can we?”

Sam took a sip of coffee and said: “No, not at the same time. Remember: You’ll only adjust the discharge-water temperature when the secondary flow is more than what one chiller can handle. When the flow is less than what one chiller can handle is the only time the VFD on the primary pump will be used. You will not need to adjust both at the same time.”

“Yes, I see that now,” Fred declared. “I’ll see you later; I need to go work on getting this into my design.”

Sam gave Fred a knowing smile. “Just remember: Figuring out when to turn a chiller on is easy compared with figuring out when to turn it off,” he said. “See you later.”

-------------------------------------------------

A few weeks had gone by, and there still was no sign of Fred. That was to be expected; it was crunch time on Fred’s project, and he undoubtedly was very busy. One afternoon, as Sam stared out the dining-room window and his lunch grew cold, Nurse Julie approached from behind.

“You have a visitor,” she said.

Sam turned to see Fred.

“I brought you a burger and some fried cheese curds,” Fred said.

Sam smiled. “So, did you figure out when to turn off a chiller?” he asked.

Fred reached into his leather workbag and pulled out his sketch from his previous visit (Figure 5), placing it on the table before Sam.

“I looked at that from several angles and made a lot of sketches,” Fred said. “I can tell you that if we still had constant flow through the chillers, the delta-T between the water leaving the chillers—T4—and the return-water temperature downstream of the bypass—T3—would indicate the load, and we could just stop a chiller when the delta-T got below 80 percent of the design delta-T. Varying the primary flow makes calculating the total load more complicated; we will have to use a flowmeter to measure the primary flow in addition to the temperature differential. That flowmeter can get pretty expensive.”

“How accurate does the flow measurement need to be?” Sam asked. “And what happens if the calculated load is a little off?”

Fred pondered this. “I suppose we could just use the pressure drop across each chiller as a rough measurement of flow,” he said. “We can get a fairly good differential-pressure sensor at a reasonable price. It still seems rather complicated to me. Sometimes we are varying the setpoint temperature of the chillers, and sometimes we are varying the flow through the chillers. To top it off, we need to figure out—on the fly—what the building load is.”

Sam smiled. “OK, let’s review,” he said. “We will either be changing the flow through the chiller or changing the discharge setpoint. Both of those will not happen at once. That takes some of the complication out of the system. The way I see it, there are four conditions we need to consider. They result from the combinations of whether the load is more or less than the chiller capacity and whether the flow is more or less than the chiller maximum flow.

“First, if the load is more than the chiller capacity and the flow is less than the chiller maximum flow—which probably is not going to happen in your low-delta-T-prone system—another chiller would need to be started,” Sam said.

“Second, if the load is less than the chiller capacity and the flow is greater than the chiller maximum flow, then you lower the chiller discharge temperature—T4—to maintain the secondary water temperature—T1—to deal with the low delta-T,” Sam continued.

“Third, if the load is more than the chiller capacity and the flow is greater than the chiller maximum flow, another chiller would need to be started,” Sam added.

“Fourth, if the load is less than the chiller capacity and the flow is less than the maximum chiller flow, the flow through the chiller can be adjusted by the VFD on the primary pump down to the minimum flow through the chiller,” Sam concluded. “Once you get down to that minimum flow, you will have to just cycle the chiller. That will cause some problems with maintaining the secondary supply-water temperature at T1, but, hopefully, that will be OK.”

“Actually,” Fred said, “there is something you can do with a thermally stratified buffer tank for better efficiency and discharge-water temperature, but I promise I will come back sometime to tell you about that one. I would guess we would be in the fourth condition with two chillers running and the VFDs on the primary pumps running near their minimums. Of course, if the chillers get to their minimums, I can turn one chiller off. But the ratio between minimum and maximum chiller flows is less than 80 percent, so I should turn a chiller off before I get to the minimums on both chillers. I seem to be edging back to that expensive flow station on each chiller or on the main.”

“There might be another way,” Sam said. “What will the temperatures in and out of a chiller be right before you should shut off the chiller?”

“Because we are in the fourth condition, the primary discharge-water temperature—T4—will be the same as our secondary supply-water temperature, T1,” Fred said. “The temperature at T3 coming back to the chillers will vary with the amount of low delta-T we have, but we will be measuring that temperature.”

“OK,” Sam said. “Remember your pump affinity laws. How is pump flow related to pump speed?”

“Pump flow is directly related to pump speed,” Fred answered.

“With a good balancing report, you will know the pump speed at maximum chiller flow,” Sam said. “Given the pump speed at a current point, you should be able to calculate a theoretical flow at the current point. Flow and delta-T will give you the load. Yes, I know it will not be exact, but it will be close enough.

“Could the low delta-T flow be so great that even if the load is below one chiller’s capacity, two chillers would be needed to serve the load?” Sam asked.

“No, that is what we went through before,” Fred said. “As long as the load is really below what one chiller can do, we can just lower the chiller discharge-water temperature to maintain our discharge-water temperature.”

The burger and cheese curds were long gone and it was getting dark outside. Nurse Julie waved to them on her way out for the evening.

Fred leaned back in his chair, placed his hands behind his head, and yawned. “This has been very helpful,” he said.

“Of course, you know, getting rid of all of your bypass valves would help with the low-delta-T symptoms,” Sam said.

“I can’t get rid of my minimum-flow three-way valves,” Fred replied. “My secondary pumps have to have a minimum flow or bad things will happen.”

Sam grinned. “There is rarely only one solution to a problem,” he said. “I have to go take my evening nap, or I will be no good at the midnight poker game. See you later.”

As Sam shuffled away, Fred was left wondering how he could get rid of all of the three-way valves.

-------------------------------------------------

A few weeks later, Fred was back.

“Hello, Sam.”

“Well, Fred, here you are again.”

“Yes,” Fred replied. “I have been thinking about how to get rid of the minimum-flow three-way valves in my system. I think I have it worked out, but wanted to discuss it with you. Nurse Julie told me it is about time to eat. I can talk while you eat.”

In short order, Sam’s lunch was served and Fred pulled out his sketch (Figure 5).

“The key to getting rid of the three-way valves is to figure out what problem you really are trying to solve,” Fred said. “I did some investigating as to why there is a minimum flow on pumps.”

Sam smiled. “Ah, and what did you find out?” he asked.

“The reason has nothing to do with the pump,” Fred said. “It is all about the motor on the pump. Most motors have a fan attached to the rotor. If the speed of the pump drops too low, there will not be enough cooling for the motor. Less RPM on the pump is not a problem with seals, shafts, or bearings.”2

“So, what do you do?” Sam asked.

“The three-way valves have a balancing valve in their bypass,” Fred said. “We will just shut each of those. That part is simple, but we still have to make sure the pump speed does not get too low.”

“When could it get too low?” Sam asked.

Fred smiled; he suspected Sam already knew the answer. As Sam started in on his roast chicken, Fred explained: “The speed of the pump usually is controlled by either the pressure differential at a remote coil-control-valve combination or by the position of the most open control valve. In our case, we use the pressure differential at the surgery air-handling-unit control valves and coils, as they are the most remote. There is a chance the pump speed would get too low if all we did was shut the bypass valves. At a lower flow, the speed of the pump will be lower for a specific head. To solve this problem, we will add a minimum pump speed to the control of the pump.”

“So, what’s your minimum pump speed?” Sam asked.

“Like many things in this life, it depends,” Fred said. “Some motor manufacturers list their motors down to 6 Hz, but our motors are older, and we will only take them down to 18 Hz.”2

“That will shut off a lot more of the flow,” Sam observed.

Fred was surprised. “Sam, it should be all of the flow,” he said. “We can get to all of the three-way valves and shut off the bypass valves; there shouldn’t be any place left for the flow to get through.”

“What is the shutoff head of your secondary pumps?” Sam asked.

“About 25 ft of head at the minimum pump speed,” Fred replied.

“Most three-way valves do not have a very good shutoff capability because that is not what they are designed to do,” Sam said. “Those valves probably will not completely close against the shutoff head of the pump. Don’t get me wrong, it will not cause any problems with low delta-T. The reduced flow through the coil will really warm up that small amount of water. The potential problem is that it could needlessly increase energy consumption.”

Fred sat back in his chair, thinking, while Sam moved on to dessert, a slice of cherry pie.

“OK,” Fred said, “I see that there may be some flow forced through the three-way valves when no cooling is wanted by the pumps. The small amount of water going through the coil will actually have a large temperature rise, getting close to discharge-air temperature. How does that increase energy consumption?”

Sam put down his fork and looked intently at Fred.

“This is one of those insidious problems that almost always gets ignored because you have to look closely to even see that there is a problem,” Sam said. “Think about what is happening and how the controls will react.”

“The controls tell the three-way control valve to close the coil,” Fred said. “Because the water no longer can bypass, the pressure across the valve increases. The increase in pressure causes some flow of chilled water through the coil. So, heating the chilled water means we use more steam or hot water to maintain the supply-air temperature. And there also is the cost of cooling that chilled water back down.”

“Exactly,” Sam said. “And as far as anyone knows, the system is working perfectly.”

Sam sighed. “It will cost a bit to replace the three-way valves,” he said, “and it will cause some downtime. And it will be very hard to show any kind of a reasonable payback for replacing them.”

“So, we don’t replace those three-way valves, even though we know they are wasting energy?” Fred asked.

Sam got a wistful look in his eyes. “A lot of engineering is about where you start,” he said. “The cost of changes to an existing system is always a factor; that will limit what you can do.” Then, he looked Fred in the eye. “But you always can do better on the next project,” he added.

Sam was smiling as he shuffled down the hall on Nurse Julie’s arm. And so was Fred as he folded up his last sketch and put it in his pocket.

What if the system were variable-primary flow instead of primary-secondary? Why is year-round chilled water better for a hospital—is the free cooling the only energy saved? Let us know your thoughts by writing to [email protected]. Your comments may appear in a future issue.

References

- Trane. (1991). A new era of free cooling. Engineers Newsletter, Vol. 20, No. 3. Available at Trane Engineers Newsletter, Vol. 20, No. 3

- S. Kutin, Bell & Gossett, personal interview, January 2017.

Jeffrey Newcomb, PE, MBA, LEED AP, has been contemplating unusual HVAC systems as a consulting engineer for over 36 years. He works for IEFM Consulting Engineers in Coal Valley, Ill., for which he is responsible for project management and design. He has degrees from the University of Illinois and The University of Iowa.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].