In buildings across the country, reductions in operating budgets are delaying important equipment upkeep. This article discusses impacts of deferring maintenance on rooftop package units and outlines a cost-based preventive-maintenance protocol.

For new unitary air-conditioning and heat-pump systems, minimum energy-efficiency ratios (EERs) are 9.7 to 14 MBH per kilowatt, depending on system capacity. A substantial number of installed unitary systems, however, are operating at EERs of 9 or less, depending on condition and maintenance history.

Analysis of a rooftop package unit—RTU-2 (Photo A)—serving a retail mall in Beaufort, S.C., provides insight into the impacts of deferred rooftop-unit (RTU) maintenance. RTU-2 is an R-22, dual-circuit, 20-ton (70.1 kW), 11.2-IPLV unit. It was instrumented with 45 refrigerant and air sensors and Web-communicating data loggers in 2010 and monitored through 2013.

Construction of the mall was completed in 2003 with 11 rooftop units totaling 202 tons. A direct digital control system monitors operational conditions and controls the RTUs. Occupied hours are 6 a.m. to 11 p.m. Monday through Friday, 8 a.m. to 11 p.m. Saturday, and 8 a.m. to 10 p.m. Sunday. The area served by RTU-2 is a large open retail space with high ceilings that is subject to frequent door openings, which provide uncontrolled, but effective, fresh-air ventilation. Lighting, customers, electronics merchandise, and refrigerated display cases represent significant heat loads.

Findings

When first evaluated in 2010, RTU-2 had been in operation for seven years. Its field-measured integrated energy-efficiency ratio (IEER) was 7.8 MBH per kilowatt, 30 percent below its factory rating. Power demand had climbed by 28 percent, from 23.7 kW at 95°F ambient to 30.3 kW.

Five service companies were engaged before RTU-2 was returned to good working order. The first four performed only routine maintenance, such as rinsing the condenser coil and checking the refrigerant charge. The fifth corrected sensor wiring and switched circuits, replaced a compressor and two fan motors, replaced both liquid line driers twice, removed clogged suction line filters, flushed circuits, adjusted and fine-tuned the refrigerant charge, tested the compressor oil for acid and moisture, and cleaned the condenser and evaporator coils.

The electrical/controls wiring had been modified over the years as various service technicians rushed to work around and bypass emergency problems. Note the wire nuts, jumpers, and other non-factory wiring in Photo B. The compressor contactors had been switched to make Compressor 1 activate with Stage 2 and vice versa. The condenser-fan relay had been bypassed. The low-pressure safety switches also were reversed, which resulted in Compressor 1 continuing to operate after a refrigerant leak and eventually failing. Previous compressor replacements left too much oil in the system, resulting in compressor burnout and the system needing to be flushed.

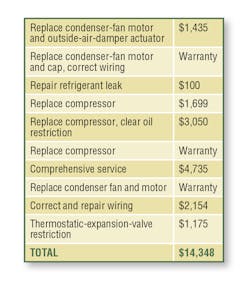

The total cost of service and repair related to deferred, improper, or neglected maintenance was $14,348 (Table 1). The service needs of RTU-2 snowballed, beginning with a condenser coil that had not been cleaned in years and an undetected failure of one of the two condenser-fan motors (Photo C). The result was very high compressor pressure, temperature, and amp draw that ultimately resulted in compressor failure. This led to warranty replacements of a condenser-fan motor and compressor, presumably because of a defective part or improper installation of the initial replacements. Coil refrigerant restriction and thermostatic-expansion-valve (TXV) failure, which were time-consuming and costly to diagnose and correct, likely were caused by the compressor failures.

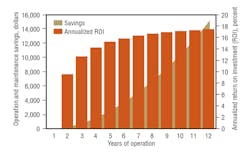

After servicing, the field-measured IEER of RTU-2 improved from 7.8 to 9.5. (Field-measurement accuracy was calculated to be ±0.6 IEER points.) This 22 percent performance improvement amounts to energy savings of $1,870 per year. Further improvement to approach the factory-rated IEER of 11.2 would require replacement of the condenser coil and possibly the other compressor, which was deemed not cost-effective. At an IEER of 9.5, RTU-2 was operating 11 percent below its factory rating, which is reasonable, considering the unit has been in service for nine years and has an expected life of 12 to 15 years. The repair work will result in a total energy savings of $11,220 over RTU-2’s six remaining service years.

Impacts

Comprehensive preventive maintenance performed twice a year over the first seven years of RTU-2’s service life would have cost $5,600 (approximately $800 per year). Assuming linear straight-line deterioration in performance, the added energy cost of deferring maintenance was $8,400. If RTU-2 had been allowed to continue to deteriorate, the added energy cost through 12 years of service would have been $15,000, and unit life likely would have been shortened by three years. Clearly, thorough preventive maintenance performed twice a year would have paid for itself, with a 50-plus-percent return on investment over a 15-year life cycle.

Over its first several years of service, an RTU can experience a 20- to 30-percent degradation in energy efficiency with no noticeable change in operation. The reality is many facility managers are unaware RTUs are operating at low efficiency levels, as most RTUs are oversized and cool adequately even when performance has degraded.

In addition to higher energy and repair costs, impacts associated with deferred RTU maintenance include liability. Component breakdowns, system failures, and unit shutdowns—classically at the most inopportune times—become more common. This puts not only systems, but building contents and occupants, at increased risk. Meanwhile, maintenance-staff productivity suffers. A study of thousands of buildings1 found a direct correlation between decreased or deferred maintenance and increased occupant complaints.

In the business world, deferring maintenance might make economic sense. Unfortunately, funds that should be allotted for critical maintenance often become unavailable for extended periods of time, leading to irreversible equipment damage. In the absence of an emergency fund, the financial impact of an RTU failure requiring immediate attention typically is borne by a maintenance budget. Maintenance budgets usually are intended to fund ongoing routine service and minor maintenance, not major corrective maintenance. A single unplanned air-conditioning outage can cost thousands of dollars and divert maintenance staffers from their scheduled duties.

Often, preventive maintenance is eliminated to make room for non-scheduled, unfunded, corrective maintenance requiring immediate attention. A sustained reduction in preventive maintenance accelerates the deterioration of equipment. Clearly, maintenance budgets are not satisfactory funding sources for the consequences of deferred maintenance.

Recommendations

When faced with an urgent need to repair a failed air-conditioning unit, most facilities managers choose to apply maintenance funds. This can be avoided by maintaining separate budgets for scheduled preventive maintenance and unplanned/emergency repairs.

Preventive-maintenance protocols for RTUs should vary according to unit size and age. The larger and newer a unit, the greater the potential for long-term savings and, thus, the greater the amount of attention the unit should receive. Energy savings from preventive maintenance are $50 to $100 per ton per year; allocating at least $50 to $75 per ton annually for preventive maintenance is recommended.

For energy efficiency, the most critical preventive-maintenance actions for RTUs, in descending order of priority, are:

- Cleaning the condenser coil.

- Verifying operation of the condenser fan(s).

- Adjusting refrigerant charge.

- Verifying proper economizer operation.

- Checking compressor discharge temperature.

- Testing compressor oil for the presence of acid.

- Testing high- and low-pressure cutout switches.

- Adjusting the TXV.

- Checking and adjusting the blower belt.

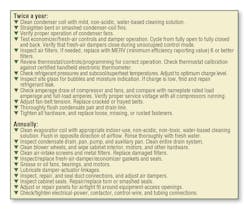

A prioritized checklist of RTU preventive-maintenance tasks is presented in Table 2. Comprehensive service should be performed at the onset of cooling season, with higher-priority tasks performed again near the end. The former takes a competent technician four to five hours to complete, while the latter takes three to four hours.

Routine maintenance should be scheduled before cooling season begins and again at the end of cooling season, as top service personnel typically are busy performing urgent repairs mid-summer. Also, rooftop temperatures are much more favorable to quality work during the shoulder seasons than mid-summer.

Seek the highest-quality service companies, ones focused exclusively on preventive maintenance of RTUs. Within even high-quality service companies, technician experience and training can vary greatly. The maintenance described in this article calls for well-trained, factory-certified, highly experienced technicians—the best of the best. Cursory service at low prices is not the least expensive. Contract or incentivize service companies in a way that emphasizes maximum performance of existing equipment and discourages replacement without consideration of life-cycle cost.

Reference

1) Sahay, R.R., & Wozniak, A.L. (2005, June). Air quality guidelines established for microbiological assessment of residential and commercial buildings. HarrisMartin COLUMNS—Mold.

Bibliography

Cowan, A. (2004). Review of recent commercial rooftop unit field studies in the Pacific Northwest and California. Portland, OR: Northwest Power and Conservation Council and Regional Technical Forum.

Downey, T., & Proctor, J. (2002). What can 13,000 air conditioners tell us? Proceedings of the ACEEE 2002 Summer Study on Energy Efficiency in Buildings.

EPRI. (1997). The impact of maintenance on packaged unitary equipment. TR-107273 3831. Electric Power Research Institute.

Hewett, M.J., et al. (1992). Measured energy and demand impacts of efficiency tune-ups for small commercial cooling systems. Proceedings of the ACEEE 1992 Summer Study on Energy Efficiency in Buildings.

Stucky, D., & Whitefield, J. (2002). Evaluating deferred maintenance as a driver for energy management programs in higher education. Energy Efficiency Journal, 9.

Sullivan, G.P., Dean, J.D., & Dixon, D.R. (2007). Top operations and maintenance (O&M) efficiency opportunities at DoD/Army site. PNNL-16615.

A member of HPAC Engineering’s Editorial Advisory Board, Michael West, PhD, PE, is a building-systems scientist who investigates and engineers solutions to high-energy-cost, maintenance, and comfort concerns. A recipient of the Association of Energy Engineers’ International Project of the Year award, he has extensive experience applying renewable sources of energy and directing the development and testing of cutting-edge HVAC technologies. Richard Combes, PhD, PE, is an energy-efficiency engineer with more than 38 years of experience conducting and managing energy and environmental projects. He has bachelor’s and master’s degrees in mechanical engineering, a master’s degree in technology and science policy, and a doctorate in history of technology from the Georgia Institute of Technology. Earlier this year, he and West received the 2013 Environmental Security Technology Certification Program Energy and Water Project of the Year Award from the U.S. Department of Defense.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].