Occupying the top two floors of the 13-story University of Miami Miller School of Medicine in downtown Miami and spanning 60,000 sq ft, UHealth Fitness and Wellness Center includes a 15,000-sq-ft fitness floor with more than 100 pieces of cardio and strength equipment, four group-fitness instructional classrooms, and a restaurant.

In an effort to improve the indoor-air quality (IAQ), the facilities-management team tried increasing the amount of outside-air ventilation, but the HVAC systems had a difficult time maintaining a comfortable temperature and humidity level. Further, the energy consumption of the HVAC equipment already was quite high, and adding more hot, humid outside air significantly increased utility costs. Lastly, increased outside-air ventilation resulted in an increase in the amount of fine particulate matter coming in from the neighboring highway.

To scrub the air of contaminants and reduce the amount of outside-air ventilation required, enVerid and Johnson Controls installed three of enVerid’s HLR (HVAC Load Reduction) modules in the mechanical rooms serving UHealth Fitness and Wellness Center in June 2015.

The project was led by enVerid and three facilities-management leaders from the university: Ron Bogue, vice president for facilities and services; Marcelo Bezos, director of energy-management systems; and Carl Thomason, energy manager. National Renewable Energy Laboratory (NREL) performed independent measurement and verification of energy savings and IAQ.

Before the HLR modules were shipped, the enVerid project team assessed the HVAC mechanical environments, provided a detailed installation plan, obtained necessary permits, developed an energy metering and monitoring plan, and collected and analyzed air samples for baseline IAQ.

During the installation phase, the enVerid project team selected and supervised electrical and mechanical subcontractors. Installation was completed with no disruption of HVAC service.

Wireless technology was installed to feed air-quality data into the enVerid Internet of Things cloud-based platform for 24/7 monitoring. Each HLR module underwent acceptance testing. Following the testing of each module, final acceptance testing for the building was completed. Air testing and balancing was performed by Miami-based Air Balance and Diagnostic Co.

The three HLR modules went live in July 2015. Each includes patented sorbents housed in proprietary cartridges that adsorb carbon dioxide (CO2), formaldehyde, and volatile organic compounds (VOCs). Each also has a set of sensors measuring temperature, relative humidity, CO2, and VOCs. The modules interpret the output of these sensors using control algorithms to actively and automatically manage IAQ and outside air.

Energy and Air-Quality Measurement

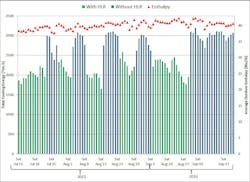

NREL validated and confirmed the energy savings of the HLR system. The energy consumption of the HVAC system was measured daily to compare days when the HLR modules were operating with days when the HLR modules were off.

Measurement started on July 11, 2015, and was completed on Sept. 5, 2015. Energy consumption was measured using an energy meter installed by the building’s facility-management team. Chilled-water consumption and outdoor conditions also were monitored.

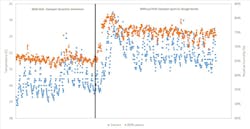

When the HLR system was in use, outside-air volume was reduced by 75 percent. When the HLR system was not in use, the ventilation rates were set according to the ventilation-rate procedure of ANSI/ASHRAE Standard 62.1-2013, Ventilation for Acceptable Indoor Air Quality. To further confirm the savings, energy consumption was measured again in 2016, from Aug. 14 until Sept. 21.

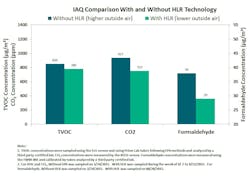

For IAQ, contaminant concentrations were measured before the HLR modules were installed and then again after the HLR modules were installed and had been running for at least one week. IAQ monitoring was performed per U.S. Environmental Protection Agency standards and the results were analyzed by a third-party certified laboratory, Prism Analytical Technologies.

The investigation included sampling of temperature, relative humidity, CO2, VOCs separated by species, total VOCs (TVOCs), formaldehyde, and particulate matter less than 2.5 μm (PM2.5) in size, including all of the typical contaminants of concern in buildings. The investigation included sampling at six locations. To prevent instrumentation-based discrepancies, the instruments used for each type of measurement, along with the manufacturer-reported detection principle, resolution, and uncertainty, were tracked.

Impact

Energy savings. With the HLR modules, UHealth Fitness and Wellness Center uses about 75 percent less outside air, saving 828 ton-hours of cooling per day for a 28-percent reduction in total HVAC energy consumption. As a result, the building is saving $19,500 in energy a year.

The energy savings would be greater if temperature and humidity inside the building were kept constant. When the HLR system is off, the humidity is 10 percent higher and the temperature is a couple degrees warmer.

Peak HVAC capacity reduction. The HLR system has reduced peak HVAC load by 56 tons, corresponding to a roughly 41-percent decrease in total HVAC load. This not only impacts utility-bill demand charges, when UHealth Fitness and Wellness Center replaces the HVAC equipment in the future, it will provide significant capital expense savings.

As with energy savings, peak-load reduction would be greater if temperature and humidity inside the building were kept constant.

Improved IAQ. With the HLR modules, the minimum ventilation rate and IAQ (pollutant concentrations) are compliant with the ANSI/ASHRAE Standard 62.1 Indoor Air Quality Procedure (IAQP).

Contaminant levels are maintained below established thresholds. Table 1 shows average measurements of the key contaminants of concern. The reduction in outside-air ventilation means less particulate matter and hazardous chemicals from the neighboring highway are being brought into the building, which further improves air quality. (A growing number of studies show living near a highway increases the risk of cardiovascular disease.)

Additional savings.

- Filters. A 75-percent reduction in outside air can double the life of outside-air filters. Given that UHealth Fitness and Wellness Center is next to a major highway, fewer filter changes can save hundreds of dollars a year.

- Reduced water consumption. Difficult to confirm because the university uses a central chiller plant, water savings for UHealth Fitness and Wellness Center are believed to be thousands of dollars annually.

- Reduced corrosion. Reduced outside-air intake reduces the introduction of saline-laden outside air, which provides several secondary benefits, including extended mechanical-equipment and ductwork life.

Summary

Facing higher-than-desired energy costs and with a commitment to high air quality and comfort, UHealth Fitness and Wellness Center turned to enVerid for help. The enVerid project team assessed the HVAC mechanical environments, provided a detailed installation plan, and obtained the necessary permits.

During the installation phase, the enVerid project team selected and supervised electrical and mechanical subcontractors. Installation of three enVerid HLR modules was completed without a disruption in HVAC service.

The project resulted in:

- A 28-percent average reduction in total HVAC energy consumption ($19,500 in savings per year).

- A 41-percent peak HVAC capacity reduction.

- A 75-percent average reduction in outside air.

- A 10-percent decrease in relative humidity and a 2.5°C reduction in air temperature.

- Improved IAQ.