Primary/Secondary-Loop vs. Primary-Loop-Only Systems

Subdividing various systems into a primary/secondary (P/S) loop via a hydraulically dependant interconnection long has been a standard solution for central chilled-water plants in the United States and Europe. This achieves, at a relatively low cost, reasonably good hydraulic separation of central-water-plant cooling-generation systems (primary loop) from distribution piping and terminal units (secondary loop). Primary-loop flow is relatively constant, while secondary-loop flow varies based on load demand. Primary- and secondary-loop water flows are interchangeable.

In a primary loop, control is achieved by maintaining a relatively constant flow rate; water temperature may be changed via a reset control. This commonly is referred to as a qualitative control strategy. In a secondary loop, control typically is achieved by varying water-flow rate. This commonly is referred to as a quantitative control strategy.

Figure 1 depicts a system with a constant- or variable-flow primary loop and a variable-flow secondary loop. The dedicated constant-speed Pump 1 maintains practically constant flow in the primary loop (the pump does not have variable-frequency-drive [VFD] control), even if flow in the secondary loop (which has its own pump, variable-speed Pump 2) varies significantly.1,2 Pump 1 is sized to maintain water flow between the chiller evaporator’s minimum and maximum allowable values.

Typical Control Strategy

In the system in Figure 1, the direction of water flow in the decoupling pipe is not controllable and may vary, depending on the ratio of flow in the secondary and primary loops.

Various modes of operation of the system were investigated.3,4 The major parameters in the evaluation of energy efficiency were supply- and return-water temperature and flow rate before and after the decoupling pipe separating the primary and secondary loops.

Mode 1. When water flow in the secondary loop (F2) exceeds water flow in the primary loop (F1) because of a load increase, a portion of the water returning from the secondary loop recirculates into the supply-distribution system (A-to-B direction) and mixes with the flow in the primary loop. This mode of operation is represented by the following equations: F2 > F1, t3 > t1, t2 = t4, and (t4 − t3) < (t2 − t1).

Mode 2. When water flow in the secondary loop (F2) is less than water flow in the primary loop (F1) because of a load reduction, flow in the decoupling pipe reverses (B-to-A direction). Thus, the excessive flow exiting the cooling-generation system returns to the primary-loop system and the chiller. This mode of operation is represented by the following equations: F1 > F2, t1 = t3, t2 < t4, and (t4 – t3) > (t2 – t1).

Mode 3: When the flow in the primary loop (F1) equals the flow in the secondary loop (F2), there is no flow in the decoupling line. All water from the secondary loop returns to the primary loop and chiller, while all water exiting the chiller flows through the secondary loop. This mode of operation is represented by the following equations: F1 = F2, t1 = t3, t2 = t4, and (t2 – t1) = (t4 – t3). Obviously, this mode of operation is the most beneficial from an energy perspective.

Optimized Control Strategy

Figure 1 depicts the optimized control strategy (Mode 3). Unlike a system with an optional constant-speed primary-loop pump, the system has an additional VFD controlling the speed of the primary-loop pump. The rate of water flow in the secondary loop via Pump 2 is dependent on system load. Water-flow rate in the primary loop is a function of water-flow rate in the secondary loop and adjusted to maintain equalized flow.

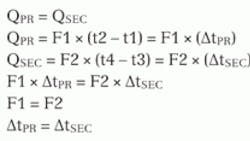

Following are simplified thermal-balance equations applicable for both primary and secondary loops, assuming the specific heat of water does not change appreciably:

where:

QPR = Primary-loop cooling load, British thermal units per hour

QSEC = Secondary-loop cooling load, British thermal units per hour

∆tPR = Primary-loop temperature differential, degrees Fahrenheit

∆tSEC = Secondary-loop temperature differential, degrees Fahrenheit

Equations 5 and 6 essentially represent the algorithm for the control of chilled-water plants. For the system in Figure 1, control is accomplished by varying the speed of Pump 1. The pump’s speed should not be reduced to the extent water-flow rate falls below the allowable low limit or increased to the extent water-flow rate exceeds the allowable high limit.

The building-automation system would have to limit VFD-turndown and turn-up ratios to stay within the range of allowable current frequencies correlated to the range of allowable primary-loop water-flow rates. To better match primary- and secondary-loop water-flow rates, two-phase control is suggested. The first phase could consist of quantitative control in both the primary and secondary loops (Equation 5) while the chilled-water-supply temperature remained at a given constant value. The second phase could consist of qualitative control in the primary loop and quantitative control in the secondary loop. (The order in which the control actions are implemented may vary.) Reset water-temperature control (Equation 6) could be realized by varying water temperature (t1) at a given fixed (limited) magnitude of water-flow rate in the primary loop. The change in water temperature would impact flow rate in the secondary loop indirectly; flow via the primary-loop pump could not be changed further because of the aforementioned evaporator-flow limitations. The P/S-loop system with variable flow and temperature control in both loops in Figure 1 is very versatile, allowing the establishment of flow-limiting parameters and temperature set points (t1) over a given time period.

Primary-Loop-Only-Variable-Flow Control System

A primary-loop-only-variable-flow (PLOVF) control system employs a single pump to circulate water through generation- and distribution-system piping loops (Figure 2). This arrangement allows uniformly distributed variable flow throughout entire systems. The generation- and distribution-piping systems have a dependant flow-control arrangement, unlike the generation- and distribution-piping systems in the P/S-loop system in Figure 1, which have an independent flow-control arrangement with two dedicated pumps. When flow in a PLOVF distribution system varies because of a load change, a VFD control varies the speed of the pump. If flow in the distribution system falls below the chiller's low limit, an automatic control valve modulates to divert flow from the supply line of the distribution system back to the chiller (A-to-B direction). This system, unlike the P/S-loop system in Figure 1, does not have the ability to bypass the chiller if flow in the distribution system exceeds the chiller's high-limit flow. For this capability to be provided in a PLOVF system, a second controllable decoupling pipeline with automatic control valve and reversed flow direction would have to be added on the other side of the pump. Otherwise, another chiller, as well as ancillary equipment (i.e., chilled-water pump, cooling tower, condenser pump), would have to be placed online, which would result in increased chiller-plant power demand as soon as flow in the distribution system exceeded the high-level limit.

A PLOVF system essentially is capable of maintaining limited total flow rate. Typically, control of systems with flow-rate-limiting devices5 is achieved by assigning priority status to one of the two loads. For instance, in a district-heating-system customer substation with space-heating and domestic-hot-water loads, priority is given to the domestic-hot-water load. The space-heating load has substantial thermal inertia and the ability to temporarily accept a lower water-flow rate without noticeable impact on air temperature. In a PLOVF system, two systems that typically have low thermal inertia (space cooling) or no inertia at all (chiller-evaporator-water flow) share the same level of priority control.

Control of a PLOVF system is somewhat more challenging than control of a P/S-loop system. This is because a PLOVF system has to maintain two variables that are continually "fighting": a given set point of pressure differential (∆P2) in the distribution-system loop and a given set point of pressure differential (∆P1) in the generation-system-piping loop. Thus, overall control-strategy execution and system operation may be less accurate and stable, and an allowance for the possible deviation from the control-parameter set point may have to be made. Typically, to avoid a chiller shutting down because of insufficient flow, the set point for low-limit flow via the evaporator is increased. Because any problems with the modulating control valve could impair system performance or even shut down the entire chilled-water system, the application of reset chilled-water-temperature control during off-design conditions (when the chilled-water-flow limitation is in place) is difficult. In comparison with a P/S-loop system, design chilled-water temperature may be constant and elevated in a PLOVF system, which may lead to increased costs for distribution piping, pumping, cooling coils, etc.

Chilled-Water-System Temperature Differential

Chilled-water temperature differential is critical to P/S and PLOVF operations in that it determines chilled-water flow per cooling ton. Impacting chilled-water temperature differential most significantly are the end-users connected to chiller plants. Take, for instance, an air-handling unit (AHU) with the following parameters:

- Air is cooled in a counterflow chilled-water coil.

- The design cooling load is 28.5 tons.

- The design sensible and latent loads are 76 percent and 24 percent of the design cooling load, respectively.

- The cooling load varies in direct proportion to outdoor dry-bulb air temperature.

- The cooling coil has a two-way chilled-water control valve to vary water flow through the coil to satisfy loads.

- The cooling coil is selected for 15°F design chilled-water temperature differential.

- The design chilled-water flow via the cooling coil at 40°F inlet water temperature is 45.7 gpm.

End-user load control. The authors considered two types of AHU cooling-load-control systems: constant airflow control (CAFC) and variable airflow control (VAFC). Maximum airflow turndown ratio was assumed to be 3.4 at a relative cooling load of 0.29 and lower. The top graph in Figure 3 shows the CAFC system requires a substantially greater change in relative chilled-water flow to achieve the same level of variation in cooling-coil load. For instance, for cooling-coil capacity to be reduced to 40 percent of the design load, relative chilled-water flow would have to be reduced to about 21 percent of its design magnitude. For the same reduction in cooling-coil capacity to be achieved with the VAFC system, relative chilled-water flow rate would have to be reduced to about 35 percent of its design magnitude. The bottom graph in Figure 3 indicates the CAFC system will increase the relative chilled-water temperature differential by a factor of about 1.9 when the relative cooling load is reduced to 40 percent of its design magnitude. For the same conditions, the VAFC system will increase relative chilled-water temperature differential by a factor of only about 1.2. Thus, the same relative reduction in chilled-water flow via the cooling coil would result in about 1.6-times-higher relative chilled-water temperature differential with the CAFC system than it would with the VAFC system.

Chiller-evaporator low-limit flow control. Various control strategies can be utilized to ensure the sustainability of a system's low-limit chilled-water flow. Figure 4 shows the reset water-temperature control required to maintain a given low-limit water-flow level when relative cooling load changes from 0.64 to 0.17 of design. The temperature of water entering the cooling coil increases as load decreases. Limited chilled-water flow is maintained by increasing the temperature of water entering the cooling coil.

The variation in relative cooling load from 0.67 to 0.17 requires the temperature of water entering the coil to be increased from 40°F to about 52°F. The bottom graph in Figure 4 indicates chilled-water temperature differential will be reduced from 15°F at the relative cooling load of 0.67 to 3.7°F at the relative cooling load of 0.17.

Other factors impacting chilled-water-system temperature differential. Chilled-water temperature differential also can be impacted by deposits on the inside and outside surfaces of cooling coils. Proper and timely cleaning of heat-exchanger heat-transfer surfaces, thus, is important,6 as is cleaning of chilled-water cooling coils and chiller evaporators and condensers.

Because of the complexity of real-life conditions, it is unrealistic to expect an increase in cooling-coil chilled-water temperature differential coinciding with a reduction in cooling load. If a system is balanced and well-maintained, temperature differential will remain relatively close to its design value during off-design conditions.

Distribution-piping-system design temperature differential. Distribution-piping-system design temperature differential impacts the installed and operating costs of central chilled-water systems. For retrofit projects, such as conversion from direct-expansion cooling coils to central chilled-water cooling coils, the cost of distribution piping could run as high as 30 percent of the entire system.3,4

Design temperature differential for the example chilled-water primary piping system was assumed to vary from about 2.1°F to 22.4°F (Table 1). The magnitude of the temperature differential at the chiller’s design cooling load was limited by the allowable minimum and maximum flow at a given number of evaporator passes. Low-level flow rate was specified to ensure evaporator operation with sufficient heat-exchanger-tube water velocity. High-level flow rate was specified to ensure evaporator operation with allowable heat-exchanger-tube velocity and avoid unstable heat transfer and tube erosion. Lower water-flow rates relate to higher chilled-water temperature differentials and vice versa.

Table 1 indicates temperature differential is dependent on number of evaporator passes. It shows evaporator relative water-flow rate remains the same (i.e., 3.6—the ratio of maximum to minimum tube water velocities) for all considered number of evaporator passes.

Allowable minimum chiller relative cooling load (MCRCL) in Table 2 was calculated using the following equation:

MCRCL = [1 ÷ (∆TDEMAX ÷ ∆TDEMIN)] × SOSF × 100, %

where:

∆TDEMAX = maximum chiller-evaporator design temperature differential

∆TDEMIN = minimum chiller-evaporator design temperature differential

SOSF = system operational safety factor, which increases minimum chilled-water flow via a chiller's evaporator (for PLOVF) to prevent chiller shutdown on low flow

The higher water-flow turndown ratios (WFTDRs) in Table 2 are advantageous because they allow optimal operation of a system to satisfy cooling loads.

Chilled-Water Turndown Ratio and Energy Savings

Figure 5 shows WFTDR patterns for various control strategies. The system was assumed to use mechanical free cooling at outdoor dry-bulb air temperatures of 55°F and below. Also, system cooling load was assumed to change linearly in direct proportion to outdoor dry-bulb air temperature.

The following options, shown in Table 2, were considered:

Option 1

∆TDEMIN = 15°F, ∆TDEMAX = 22.4°F, WFTDR = 1.5

This means relative chiller-evaporator chilled-water flow could be reduced to 67 percent of its design value.

Relative chilled-water flow via the pump serving the PLOVF system in Figure 2 will follow two straight lines outlined by the triangle ACB in Figure 5 and remain constant at the level designated by straight line CB. Although relative water flow via the distribution-piping system will follow the load change, the bypass valve will be open to ensure the required low-limit chiller-evaporator flow is maintained. This means the pump will run at the constant flow rate indicated by the straight line CB.

P/S-loop systems with variable-primary and secondary-loop pumping could provide energy savings (compared with the PLOVF-system operation indicated by straight line DH in Figure 5) while dry-bulb outdoor-air temperature ranged from 55°F to 74°F because of the variable secondary-loop pumping (Pump 2 in Figure 1) depicted by straight line DE in Figure 5.

Option 3

∆TDEMIN = 6.2°F, ∆TDEMAX = 22.4°F, WFTDR = 3.6

This means relative chiller-evaporator chilled-water flow could be reduced to 27.7 percent of its design value.

Relative chilled-water flow via the pump serving the PLOVF system in Figure 2 will follow two straight lines outlined by the triangle AFG in Figure 5 and remain constant at the level designated by straight line FG. Although water flow via the distribution-piping system will follow the load change, the bypass valve (2) will be open to ensure the required low-limit chiller-evaporator flow is maintained. This means the pump will run at the constant flow rate indicated by straight line FG.

P/S-loop systems with variable-primary and secondary-loop pumping could provide energy savings (compared with the PLOVF-system operation indicated by straight line DH in Figure 5) while dry-bulb outdoor-air temperature ranged from 55°F to 67°F because of the variable secondary-loop pumping (Pump 2 in Figure 1) depicted by straight line FE in Figure 5.

Cooling-Load Profile

Cooling-load profile depends on the ratio of constant load (e.g., internal heat gain from lights, equipment, people, etc.) to variable load (e.g., ventilation, heat gain from building envelope, etc.).

Cumulative relative cooling load and time-duration factor for eight constant- and variable-load components in New England are given in Figure 6. The design cooling load for the process area of a manufacturing facility is close to 57 tons. The actual constant-cooling-load component was near 35 tons, or 62 percent of the design load. The actual variable-load component was close to 22 tons, or 38 percent of the design load.

Applied in energy analysis, Figure 6 is illustrative of relative cooling-load variations when the percentage of constant-cooling-load component (PCCLC) changes from 0 percent to 100 percent of total cooling load.

P/S- and PLOVF-System Electrical-Energy Usage

Chilled-water-pumping electrical-energy savings. The top graph in Figure 7 shows potential annual chilled-water-pumping electrical-energy savings for a P/S-loop system with variable-flow-rate control in both loops. The electrical energy consumed by pump motors was assumed to vary in direct proportion to changes in motor speed by a power of 2.5. This is lower than the theoretical value of 3 recommended for centrifugal pumps. These savings will be realized when distribution-system water flow is equal to or lower than the allowable chiller-evaporator low limit (Figure 5). In calculations of annual electrical-energy use, the pump serving the PLOVF system was assumed to have a design flow rate equal to the design flow rate of the P/S-loop pumps. The pump serving the PLOVF system also was assumed to have a design pressure head equal to the cumulative design pressure head of the P/S-loop pumps.

With a MCRCL of 73.6 percent (Table 2), P/S-loop-system annual electrical-energy savings vary from 5.8 percent (calculated PCCLC of 62 percent) to 60 percent (calculated PCCLC of 0 percent). Annual pumping electrical-energy usage for the considered P/S and PLOVF systems will be equalized at a PCCLC greater than or equal to 75 percent (Figure 7).

With a MCRCL of 49 percent (Table 2), P/S-loop-system annual electrical-energy savings vary from 10.4 percent (PCCLC of 26 percent) to 41 percent (PCCLC of 0 percent). Annual pumping electrical-energy usage for the considered P/S and PLOVF systems will be equalized at a PCCLC greater than or equal to 35 percent (Figure 7).

With a MCRCL of 30.5 percent (Table 2), P/S-loop system annual electrical-energy savings vary from 2.8 percent (PCCLC of 15 percent) to 9.5 percent (PCCLC of 0 percent). Annual electrical-energy usage for the considered P/S and PLOVF systems will be equalized at a PCCLC greater than or equal to 21.5 percent (Figure 7).

With an MCRCL of 73.6 percent and a PCCLC varying from 0 percent to 40 percent, the P/S-loop system with constant-primary-loop and variable-secondary-loop pumping control consumes less electrical energy annually than the PLOVF system. These savings are identified in Figure 7 as the difference in Y-axis values to the left of the intersection of the dashed lines. The savings could be as high as 22 percent at a PCCLC of 0 percent.

In calculations of electrical-energy savings, primary- and secondary-pump usage was assumed to be about 6 percent of chiller-plant annual electrical-energy consumption.

The data in the top graph of Figure 7 are related to single-chiller plants. The use of multiple chillers will increase WFTDR and reduce MCRCL. This will reduce annual pumping electrical-energy savings. Correction factors for two- and three-chiller plants are given in Table 3.

Reset-chilled-water-temperature electrical-energy savings. The P/S-loop system with variable-flow control also has savings associated with reset chilled-water-temperature control. While considering these savings, the authors assumed, based on manufacturer data, that approximately 2 percent of the chiller’s input energy would be saved per degree-Fahrenheit increase in chilled-water temperature. The increase in chilled-water temperature also would increase secondary-loop water flow, which, in turn, would reduce the electrical-energy savings associated with the secondary-loop pump employing variable-flow control. The authors incorporated that reduction in their calculations. The chiller’s power demand was assumed to be about 78 percent of the total plant power demand.

Cumulative annual electrical-energy savings. Cumulative annual electrical-energy savings for pumping and reset chilled-water-temperature control expressed as a percentage of total chiller-plant annual energy consumption are shown in the bottom graph of Figure 7. The annual savings of a single-chiller plant with an MCRCL of 30.5 percent and a PCCLC of 62 percent and a single-chiller plant with an MCRCL of 73.6 percent and a PCCLC of 0 percent vary from 0.5 percent to 5.2 percent. The annual savings of a two-chiller plant with an MCRCL of 22.9 percent and a PCCLC of 62 percent and a two-chiller plant with an MCRCL of 55.2 percent and a PCCLC of 0 percent vary from 0.4 percent to 4.1 percent.

Converting From PLOVF to P/S-Loop-With-VFD-Control System

A central chilled-water system with 2,500-ton chillers serving multiple AHUs at a New England manufacturing facility was converted from PLOVF (similar to that shown in Figure 2) to P/S-loop operation (nearly identical to that shown in Figure 1). The system had a design cooling load of approximately 930 tons and a design secondary-loop chilled-water flow of about 1,600 gpm. About 50 percent of the cooling load was constant (PCCLC of 50 percent). The P/S-loop system had two dedicated water-flow meters to separately measure the flows in the primary and secondary loops, as well as in the distribution- and generation-piping loops of the PLOVF system. To compare the hourly operational modes of the systems, the authors selected a two-day sample with approximately the same dry-bulb outdoor-air temperature for both systems. The reset chilled-water-temperature control for the P/S system was not activated during the two days. The outdoor dry-bulb air temperature ranged from 57°F to 83°F. The average daily dry-bulb air temperature was close to 69°F, while the cooling load ranged from 250 tons to 450 tons. Only one chiller was running. The high-limit chiller-evaporator flow was 1,200 gpm (i.e., ∆TDEMIN was 10°F). The low-level chiller-evaporator flow was 670 gpm (i.e., ∆TDEMAX was 17.9°F). Thus, WFTDR was 1.79.

Low-limit chiller-evaporator flow was set at 700 gpm during P/S-loop operation; during PLOVF-loop operation, it was set at 770 gpm. An attempt to lower low-limit flow during PLOVF-loop operation was unsuccessful because of evaporator-induced chiller shutdown on low flow.

Total chilled-water flow via the pump in the PLOVF system (Point F1 in Figure 2) was relatively stable, varying from about 720 to 860 gpm (Figure 8). Meanwhile, chilled-water flow via the distribution-piping system varied from 439 to 847 gpm. Chilled-water flow via the chiller's evaporator was maintained at its allowable low-limit magnitude through bypass-control-valve modulation. Chilled-water flow via the bypass control valve, which represents the difference between flow via the pump and flow via the distribution-piping system, varied from about 10 to 285 gpm. Flow via the bypass valve, expressed as a percentage of total flow via the pump, varied from about 2 percent (at higher cooling loads) to 39 percent (at lower cooling loads). Any time—and to any extent—the bypass valve (2) was open, VFD speed and pump flow remained constant, wasting electrical energy.

Chilled-water flow in the P/S-loop system varied from 700 to 816 gpm (Figure 8). Flow in the secondary loop varied from 420 to 820 gpm. Chilled-water flow via the distribution-piping system varied independently of water flow via the chiller evaporator pump. Chilled-water flow via the distribution system was reduced following the load reduction in the cooling system. This led to reduced electrical-energy use by Pump 2. Chilled-water flow via the primary-loop pump and chiller evaporator remained relatively constant, satisfying low-limit water-flow requirements via the evaporator.

The same 100-hp pump (design water flow 2,400 gpm) was used for the PLOVF system and the secondary loop of the P/S-loop system. The primary loop of the P/S-loop system had its own 15-hp pump (design water flow 1,200 gpm). The long operational hours of the PLOVF system, with nearly constant flow via the pump necessary to maintain low-limit flow via the chiller evaporator, resulted in wasted electrical-energy power demand (kilowatts) and usage (kilowatt-hours). Secondary-loop pump electrical-energy usage decreased and increased following cooling-load variations. Electrical-energy savings for the P/S-loop system varied from about 3 percent to 50 percent, averaging around 20 percent per day.

The authors have observed similar electrical-energy savings following other chiller plants’ conversion from PLOVF to P/S-loop operation.

Summary

This article compared the operational modes and performance of P/S-loop and PLOVF systems.

The operating efficiency of chilled-water systems with a primary (constant-flow)/secondary (variable-flow)-loop arrangement can be improved by applying a two-phase optimized control strategy consisting of variable flow and temperature control for primary-loop pumps and variable-flow control for secondary-loop pumps.

PLOVF-with-VFD control wastes energy when primary-loop flow is constrained by the chiller-evaporator low limit and chilled water is diverted via decoupling line from the supply pipe to the return pipe of the generation system. The magnitude of annual energy savings (pumping and reset chilled-water temperature) of P/S-loop control depends on multiple variables, such as chiller-evaporator-flow turndown ratio, minimum chiller relative cooling load, load composition, number of chillers, etc. For New England weather conditions, annual electrical-energy savings could be 0.5 to 5.2 percent for a single-chiller plant and 0.4 to 4.1 percent for a two-chiller plant.

P/S-loop-with-variable-flow control reduces chiller-plant power demand by resetting chilled-water temperature when flow in the distribution piping exceeds a high-limit value for the chiller evaporator and the system diverts water via decoupling line from the return pipe to the supply pipe of the distribution system. This prevents or delays the addition of a chiller and associated ancillary equipment and saves energy.

Compared with PLOVF systems, P/S-loop systems with variable flow also have the advantage of more-accurate, flexible, and stable control and operational conditions.

References

- Burd, A.L. (1994). Optimizing customers' heating systems to reduce capital and operating cost in district heating with cogeneration. Proceedings of International District Heating and Cooling Association Annual Conference, pp. 237-252.

- Burd, A.L. (1993). Computer design of terminal heating substations for district heating. ASHRAE Transactions, 99 (2), 245-265.

- Burd, A.L., Burd, G.S., & De Maio, M. (2005, March). Smith & Wesson: The story of a chilled-water retrofit (part 1). HPAC Engineering, pp. 38-47.

- Burd, A.L., Burd, G.S., & De Maio, M. (2005, July). Smith & Wesson: The story of a chilled-water retrofit (part 2). HPAC Engineering, pp. 24-37.

- Burd, A.L. (1997). Deferred heat supply for space heating using a capacity-limiting device – A beneficial approach for district heating. ASHRAE Transactions, 103 (2), 23-31.

- Burd, A.L., & Burd, G.S. (1996). Optimal cycle for plate heat exchanger cleaning in customer substation. Proceedings of International District Energy Association Annual Conference, pp. 177-192.

Did you find this article useful? Send comments and suggestions to Scott Arnold at [email protected].

Alexander L. Burd, PhD, PE, is president of and Galina S. Burd, MS, is a project manager for Advanced Research Technology, an engineering and research consulting firm with offices in Suffield, Conn., and Green Bay, Wis. Alexander ([email protected]) has 35 years of experience in the design, research, and optimization of HVAC and district energy systems, which includes publication of more than 35 research and technical papers in American and European journals, while Galina ([email protected]) has more than 25 years of design and research experience in the HVAC and architectural-engineering fields. She has co-authored many technical and research papers published in American journals.