Some years ago, two young and inexperienced technicians were called to work on a large refrigerant system. The system was not working properly because of an incorrectly installed valve. In their attempt to fix the system, the technicians caused a leak in the piping at the tank, which contained several hundred pounds of refrigerant.

Being heavier than air, the refrigerant gas began displacing oxygen in the normal-sized mechanical room. Little did they know—refrigerant cannot be seen or smelled—the technicians were starting to suffocate.

Within a few minutes, one technician, who had been bent over the tank attempting to fix the valve, was unconscious on the floor. The other technician, who had been standing, observing the procedure, was conscious, but essentially asleep on his feet.

Fortunately, the door to the mechanical room had been left open, and enough refrigerant escaped to trip a smoke detector in the fire alarm system. (This was in the days before code-mandated refrigerant alarms and ventilation systems.) The alarm awoke the standing technician. What he saw was a sea of white fog—the refrigerant, under higher pressure in the tank, expanded through the pipe opening and condensed—from the floor up to his chest. He dragged the unconscious technician outside, where they both were able to recover.

This incident illustrates the danger posed by a refrigerant leak.

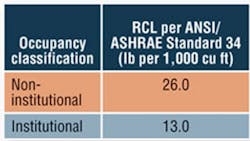

ANSI/ASHRAE Standard 15, Safety Standard for Refrigeration Systems, ANSI/ASHRAE Standard 34, Designation and Safety Classification of Refrigerants, and the International Mechanical Code (IMC) define the levels of refrigerant discharge at which poisoning and suffocation occur. In particular, ANSI/ASHRAE Standard 34 defines refrigerant-concentration limit (RCL) and oxygen-deprivation limit (ODL).

RCL is the amount of refrigerant released into a normally occupied, enclosed space beyond which acute toxicity is expected. Typically, it is expressed in pounds per thousand cubic feet or parts per million. For example, R-410A, a refrigerant commonly used in variable-refrigerant-flow (VRF) systems, has a RCL of 26 lb per thousand cubic feet or 140,000 ppm. For institutional occupancies where “occupants cannot readily leave without the assistance of others,” the threshold is half that.

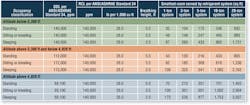

ODL is the concentration of a refrigerant or other gas resulting in insufficient oxygen for normal breathing. For refrigerant gas, ODL is 140,000 ppm at altitudes below 3,300 ft, 112,000 ppm at altitudes of 3,300 ft to 4,920 ft, and 69,100 ppm at altitudes above 4,920 ft.

Refrigerant fills a room similar to the way water fills a bathtub: from the bottom up. The incident involving the two technicians is a clear example of this: The technician who had been bent over the tank was unconscious because of the higher concentration of heavier-than-air refrigerant near the floor. Codes do not directly address how to apply this non-homogenous dispersion of refrigerant gas in a space. Nor do they directly address how to translate pounds of refrigerant to a room volume or area for easy application. These are challenges facing design engineers and contractors.

The problem can be broken down by addressing RCL and ODL separately and considering the type of refrigerant system (i.e., larger system located in a mechanical room or smaller system located in an occupied space).

Published manufacturer data show a typical factory refrigerant charge of 2 to 3 lb per nominal ton of capacity, with an additional 1 to 3 lb per nominal ton in field piping for a practical range of 3 to 6 lb per ton.1

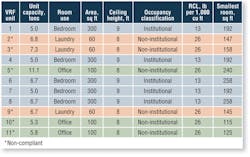

Using 4.5 lb per ton, for example, one can calculate the smallest room or zone in which RCL could be maintained if a VRF system’s entire charge of R-410A refrigerant were to leak (Table 1).

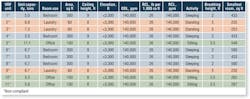

Regarding ODL, ANSI/ASHRAE Standard 15 states, “The volume used to convert from refrigerant concentration limits to refrigerating system quantity limits ... shall be based on the volume of space to which refrigerant disperses in the event of a refrigerant leak.” This is not the volume of the room, but the volume at the breathing level, or the height of a person’s head above the floor. For calculation purposes, this is 5 ft for people standing, 3.5 ft for people sitting or kneeling, and 2 ft for people lying down or sleeping.

When ODL is applied, the size of the VRF system that can safely serve a particular space changes dramatically. For example, using RCL criteria, a 100-sq-ft office (sitting activity) could be served by a 5-ton VRF system (Table 1). Using ODL criteria at breathing height, the same office can be served by only a 3-ton system at altitudes below 3,300 ft and a 1-ton system at altitudes above 4,920 ft (Table 2).

Another example: Using RCL criteria, the largest VRF system that could serve a 300-sq-ft hotel room (sleeping activity) is 15 tons (Table 1). Because a hotel room is where people sleep and “cannot readily leave without the assistance of others,” institutional-occupancy criteria should apply, and RCL should be reduced by at least 50 percent, meaning the largest VRF system that could serve the room is 7.5 tons.

Using ODL criteria at breathing level, the hotel room could be served by only a 4-ton system at altitudes below 3,300 ft and a 1-ton system at altitudes above 4,920 ft (Table 2).

This analysis assumes the worst case. Although there is no research or models to confirm them, the assumptions are reasonable, given the nature of heavier-than-air refrigerant gas.

The other important parameter in the dispersion of refrigerant gas—time—is not addressed directly in either ANSI/ASHRAE Standard 34 or the IMC, both of which appear to assume refrigerant from a leak will disperse quickly enough to avoid suffocation. That is not the case, as the two technicians described earlier found out.

Paragraph 7.3.1 of ANSI/ASHRAE Standard 15 states, “The volume of the smallest occupied space shall be used to determine the refrigerant quantity limit in the system” when “one or more enclosed occupied spaces ... do not connect through permanent openings,” but neither defines “permanent openings” nor indicates their location or size. According to one VRF manufacturer, qualifying permanent openings are:

• False ceiling voids.

• Doors with transfer grilles.

• Undercut doors.

False ceiling voids or plenums are not permitted under ANSI/ASHRAE Standard 15, unless they are used as part of an air-supply or return path. Refrigerant gas falls to the floor, not rises to the ceiling, so the additional volume a ceiling plenum offers is of no value in diluting refrigerant gas at occupants’ breathing level. Doors with transfer grilles and undercut doors are at least close to the floor and provide a path for refrigerant to migrate out of a room. According to one VRF manufacturer, if an opening’s total area is more than 0.15 percent of the floor area and is at a low position with regard to another room/space, the two rooms/spaces should be considered as one. Unfortunately, the dispersal of refrigerant in a catastrophic leak may not be fast enough to avoid suffocation, as the two technicians in the refrigerant-spill accident found out. For them, even though the door to the mechanical room was wide open to the corridor outside, the refrigerant could not disperse out of the room fast enough.

Analysis of a recent VRF project is revealing. The building is a memory-care facility classified for calculation purposes as institutional because “occupants cannot readily leave without the assistance of others.” (Non-patient areas are classified as non-institutional.) As a result, allowable amounts of refrigerant are reduced by 50 percent per ANSI/ASHRAE Standard 34.

Table 3 provides minimum room areas per the RCL for R-410A.

Note that more than half of the VRF units do not comply with ANSI/ASHRAE Standard 34 for minimum room volumes, despite the advantage of a non-institutional occupancy classification for non-patient areas.

Table 4 provides minimum room areas per the sub-3,300-ft-altitude ODL of 140,000 ppm applied at breathing level. For this calculation, none of the VRF units complies.

VRF-unit manufacturers are starting to recognize the dangers of refrigerant leaks. One has introduced a refrigerant-leak-detection-and-containment system primarily for hotels. The system is said to provide complete protection against both gradual and major leaks, automatically isolating and pumping down a refrigerant circuit in the event of a sudden loss of gas. Also, it triggers audible and visual alarms both in affected rooms and centrally via a supervisory control system.

Reference

1) Duda, S.W. (2012, July). Applying VRF? Don’t overlook standard 15. ASHRAE Journal.

A co-author of the new graduate-level textbook “Modern Geothermal HVAC Engineering and Control Applications,” published by McGraw-Hill Education, Greg Cunniff, PE, is the manager of application engineering for Taco Inc. He has written white papers and technical articles, developed engineering software and continuing-education programs, and spoken at numerous industry events.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].