Making a Case for Reduced Classroom Ventilation

Across the United States, a minimum of 15 cfm of fresh air per student is required for classroom ventilation. That is the amount set forth in ANSI/ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality (IAQ), and it is the minimum amount the U.S. Green Building Council (USGBC) will recognize through its LEED green-building certification program. In fact, the USGBC will award additional credit if 20 cfm of fresh air per student is delivered.

Twenty—and even 15—cfm of fresh air per student is excessive, with significant repercussions for the economy and the environment.

In 2006, Hillsborough County Public Schools in Tampa, Fla., the ninth-largest school district in the United States, commissioned Chastain-Skillman Inc., a consulting firm of design and public-health professionals, to determine the effect of reduced fresh-air ventilation on IAQ in public schools.

Three groups of five schools were randomly selected for testing. One group was to receive 15 cfm of fresh air per student, while the other two were to receive 7.5 and 5 cfm of fresh air per student, respectively. The testing included a walkthrough and continuous monitoring of indoor and outdoor carbon-dioxide (CO2) levels. CO2 monitors were placed in two locations per air-handling-unit zone: at the beginning of the ductwork system and at the end of the ductwork system, in areas considered typical of building conditions.

Although the district intended to evaluate 15 schools, the testing was stopped at eight—three schools that received 15 cfm of fresh air per student, two that received 7.5 cfm, and three that received 5 cfm—when the results became apparent.

The results indicated no difference in CO2 level, occupant acceptance, or absenteeism among the groups, regardless of school type (elementary, middle, high) and student socioeconomic mix. What's more, there was no difference in student performance on the standardized Florida Comprehensive Assessment Test.

The results, based on "intermittent student-occupancy usage factor"—calculated by dividing the number of hours students spend in a classroom on a typical school day (number of hours in a typical school day minus time spent for lunch, classroom changes, and out-of-class activities, such as physical education) by the number of hours of daily HVAC operation—showed good IAQ is achievable with 7.5 cfm of fresh air per student. Even with 5 cfm of fresh air per student, IAQ was satisfactory.

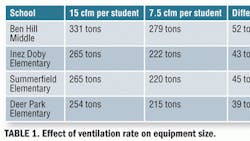

Today, Florida Building Code allows classroom fresh-air rates of 7.5 cfm per student. In Hillsborough County, that not only has reduced the size of cooling equipment (Table 1), it has lowered equipment costs by approximately $100,000 a school. Annual energy savings are approximately $10,000 a school. Nationwide, construction-cost savings would be nearly $1.65 billion a year, while energy and maintenance savings would be approximately $329 million a year.

Hillsborough County Public Schools never has had an IAQ problem attributable to a fresh-air rate of 7.5 cfm per student or even 5 cfm per student. IAQ problems the district has experienced are attributable to negative building air pressure, leaky roofs, missing vapor barriers, broken chilled-water valves, oversized direct-expansion equipment, poor control calibration, leaky windows, dirty filters, and the like.

In short, there is no need to overventilate a school, unless it is to remedy a building-pressurization problem.

A final note: Hillsborough County Public Schools chose not to use demand limiting in part because it offered no chiller-reduction savings and required additional automatic control and hundreds of CO2 sensors. Plus, exhaust systems would have to modulate as fresh air modulates to avoid building negative pressure.

Editor's note: For a free copy of the test report, contact the author at 813-635-1102 or [email protected].

Ernest MacFerran, PE, CIAQP, is responsible for the construction and maintenance of mechanical systems for Hillsborough County Public Schools. He is a recipient of a Florida Institute of Consulting Engineers Engineering Excellence Grand Award and has been named Engineer of the Year by both the Florida West Coast Chapter of the American Society of Heating, Refrigerating and Air-Conditioning Engineers and the Association of Energy Engineers.