Airflow-measurement-device selection is critical to the performance of today's state-of-the-art HVAC control systems, as accuracy and repeatability can vary dramatically between instruments. Many of the requirements and limitations of one measurement technology, however, often are thought to apply to all.

This article discusses functional and performance differences between the two most popular technologies for permanently duct-mounted measurement systems in commercial buildings: velocity-pressure devices (Pitot arrays, probes, Piezo rings, and other delta-P methods) and thermal-dispersion (TD) devices (microprocessor-based instruments using some form of thermistor sensor). It excludes vortex shedding and resistance-temperature-device-type instruments, which generally are applied in contaminated and/or high-temperature industrial environments.

THERMAL DISPERSION

Introduced in 1985, advanced TD airflow-measurement technology is used in a wide range of office, laboratory, health-care, and educational facilities. Some manufacturers produce TD instruments with a combination of electronic components, while others provide independent sensing elements. One manufacturer produces TD instruments factory-calibrated to National Institute of Standards and Technology- (NIST-) traceable velocity reference standards. When designed properly and applied with sensing elements of sufficient density, a TD instrument can minimize, if not overcome, placement limitations and measurement uncertainties inherent in the use of velocity-pressure instruments.

Pre-1993 TD arrays were influenced significantly by duct-turbulence and placement conditions. Because the technology determines airflow by relating the rate of heat transfer from a warm body to an air stream, airflow-measurement stations placed close to duct disturbances often registered "false high" readings. More heat was removed from sensors in duct locations with excessive eddies and turbulence than sensors exposed to steady-state factory wind-tunnel calibration and, thus, higher readings.

During the early 1990s, enhancements to one design placed the heated sensor in the turbulent wake created by the sharp leading edge of the sensor-probe assembly. This "preconditioning" effect essentially made airflow across the sensor more "turbulent" than the worst-case duct-disturbance effect, allowing the condition to be created consistently. During the calibration process, a known flow rate was associated with the actual conditions encountered by the sensor. As a result, TD sensors were influenced far less by duct disturbances. This has been proven in full-scale laboratory testing.1 With advanced TD instruments, 0.75 to 1.5 simple equivalent duct diameter [(width + height) ÷ 2] often is sufficient for accurate measurement. Contrast this with the three-duct-diameter minimum industry standard.

During the spring of 2000, more than 350 advanced TD devices were installed at NIST's Advanced Measurement Laboratory in Gaithersburg, Md. The devices have performed without the need for field calibration and are said to be functioning well, without a single reported sensor failure.

TD technology should not be confused or compared with thermal anemometers, hot-wire devices, or other forms of analog electronic velocity measurement, as it often--and incorrectly--is.

Hand-held thermal (single-point) instruments generally use unshielded thermistors, which makes them highly sensitive to the direction and vectors of airflow. Typically, they are analog devices and, thus, have a tendency to drift from zero. Also, they usually require regular recalibration and "zeroing" and tend to perform satisfactorily only within a narrow temperature band and at favorable locations.

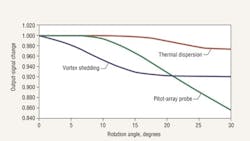

At least one permanently mounted TD product has a published operating range of -20°F to +160°F and a design limiting the impact of rotational misalignment. Tests confirm the device's immunity to improper installation (rotation of airflow angle) (Figure 1). The test was conducted by monitoring the output signal while the device was rotated perpendicular to airflow.

There are some operating conditions to which TD instruments are not immune. TD performance is dependent upon not only the transfer of energy (heat) from the sensing element to the measured air stream, but the precise determination of air-stream temperature at the point of measurement. Conditions that could affect thermal transfer (insulating materials, liquid water) also could impact the ability of an instrument to function as designed. The TD manufacturer's choice of sensing elements ultimately impacts:

- Instrument cost.

- Instrument mean time between failures.

- Instrument sensitivity to environmental changes.

- Instrument stability over time and changing temperatures.

- The instrument's ability to perform without mechanical failure amid continuous cycling between heating and cooling.

- The validity of the manufacturer's factory calibration process.

- The lack of/need for interchangeability of instrument components or subsystems.

- Limitations on product placement.

Each of these factors must be considered prior to instrument selection.

Although TD devices are subjected to condensation from coils or carryover from exterior louvers, the impact of liquid-water immersion on TD performance is temporary, with normal performance resuming as the sensor surface returns to ambient relative-humidity levels.

In rare instances, insulating materials bind to tiny thermistor sensing elements, compromising thermal-transfer characteristics. In such cases, occasional light cleaning of sensors is necessary. Typically, however, common dust and airborne particulate found in outside air and conditioned-air ventilating systems is not capable of accumulating and producing an insulating effect great enough to materially impact the thermal-transfer characteristics of a sensor.

PITOT-STATIC TUBES and VELOCITY-PRESSURE ARRAYS

The laboratory Pitot-static tube is a "primary" instrument, which means it has physical properties that have been scientifically proven to provide a predictable level of measurement performance, albeit with known application limitations. The Pitot array is not a primary instrument. The Pitot-static tube and the Pitot array share only the use of the velocity-pressure relationship in the determination of velocity and, thereafter, the calculation of air volume.

In the hands of a skilled testing-and-balancing technician at a suitable location, a Pitot-static-tube traverse is a highly trusted method of obtaining field-test information. It is important to the initial testing and balancing of many systems and the basis of many laboratory test standards (e.g., ANSI/AMCA Standard 210-07/ANSI/ASHRAE 51-07, Laboratory Methods of Testing Fans for Certified Aerodynamic Performance Rating, and ASHRAE Standard 41.2-1987, Standard Methods for Laboratory Airflow Measurement), but susceptible to error because of normal inconsistencies in human application.

There are at least six manufacturers of velocity-pressure-based duct-averaging products and at least 12 manufacturers of variable-air-volume- (VAV-) box pickups, fan-inlet Piezo rings, flow-balancing hoods, and calibration and research devices based on the same principles in North America.

As applied to commercial ventilation systems, velocity-pressure-based measurement technology has been around since the 1960s.

A pneumatic output no longer is a preferred interface for building controls, as differential pressure must be converted to an electronic signal and transmitted to host controls or an intermediate device programmed to make the analog output linear to flow. Most Pitot-array manufacturers offer pneumatic-to-electronic (P/E) transducers and other electronic control devices to enable functionality with direct-digital-control systems.

Velocity-pressure arrays, Pitot arrays, and self-averaging arrays are names for the same product species. They are bifurcated devices that separately equalize total and static pressure within a length of partitioned tubing through small sampling holes positioned at a cross-sectional plane in ductwork. A single differential pressure is measured between two compartments or equalizing manifolds and assumed to be the "average." This analog result then is output electronically to a controller or display. It is made linear by an integrated transmitter, a separate intermediate device ("square-root extractor"), or other method of calculation.

Testing-adjusting-and-balancing (TAB) contractors measure cross-sectional average velocity in a duct by recording individual readings at specific locations on a plane perpendicular to airflow direction. Each reading is determined using the following equation:

V = 4,005 × (∆P)0.5

where:

∆P is expressed in inches of water

This generalized relationship uses a constant (4,005) that assumes standard conditions of altitude and temperature. The equation does not account for changes in air density attributed to variations in air temperature and barometric pressure (altitude). The readings simply are added and divided by the number of measurements; a final average airflow rate then is determined.

Taking a high number of readings throughout a duct can help compensate for changes in velocity profile. However, it increases the time required to determine all of the data needed for averaging (ISO 3966:2008, Measurement of Fluid Flow in Closed Conduits--Velocity Area Method Using Pitot Static Tubes).

The large number of perforations in the collector tubing of Pitot arrays often is associated with the number of velocity measurements necessary to satisfy ISO 3966:2008; ANSI/ASHRAE Standard 111-2008, Measurement, Testing, Adjusting, and Balancing of Building HVAC Systems; AMCA Publication 203-90, Field Performance Measurement of Fan Systems; and any TAB requirements. The comparison, however, is physically and mathematically invalid.

Theoretically, a Pitot array averages a velocity profile; in practice, pressure equalization occurs along the length of a common collector tube, before airflow rate is determined by a single sensing element (the pressure transducer). The output of a Pitot array can represent an average reading only for a duct with equal pressure distribution throughout. Because Pitot arrays are sensitive to placement, significant lengths of ductwork are required between disturbances to develop the necessary pressure profile.

Differences between single- and independent-sensor technologies have been confirmed through laboratory testing (Figure 2).

A normal single-point velocity-pressure-to-velocity calculation assumes no difference if velocity pressure is averaged before velocity is determined at multiple points. Mathematically, a significant error (8 to 18 percent of reading) is introduced to the result, compared with independent velocity measurements (Figure 3).

In a laboratory, with professionally selected research equipment and test setup (as in ANSI/AMCA Standard 610-06, Laboratory Methods of Testing Airflow Measurement Stations for Performance Rating), Pitot arrays can produce a measurement uncertainty of ±2 percent from a reference (the laboratory). In the field, against field references, using unknown-quality P/E conversion equipment and unknown linearization methods, Pitot arrays cannot provide that level of combined total uncertainty with consistency.

Velocity-pressure devices physically sample air through many tiny ports engineered to specific dimensions. Regular maintenance must be performed to prevent clogging of the ports and ensure proper performance. Most Pitot-array suppliers offer the option of a pressurized purge system intended to reduce the manual labor associated with regular cleaning.

In some applications, repeatability, linearity, and turndown are more important than absolute accuracy. In the case of volumetric fan tracking, for example, repeatability is the only measurement attribute of importance. Fan-inlet conditions are unpredictable and extreme to the point of being undesirable. While fan-inlet airflow-measurement placement eliminates some design issues for the engineer, troublesome installation issues (e.g., access to the reverse side of dual-inlet fans) arise, as do fan-sound and fan-performance issues. These issues can be overcome by mounting to the face of the inlet, rather than the inlet throat, which reduces the potential impact on plenum-fan performance to less than 1 percent of rated flow.

The difficulty in determining a true baseline volumetric calculation and the resulting impact on control accuracy is compounded by the difficulty in determining the area of the plane in an inlet cone where a measurement device is to be installed. This is true of any airflow-measurement technology applied at fan inlets. However, when an instrument produces measurements that are repeatable, it can be set up in the field to produce reliable results. This is especially important when accessibility for maintenance or replacement is limited.

CONCLUSION

The information provided in this article is intended to enable better decisions regarding instrument selection, application, and placement. It is hoped this additional knowledge will increase the probability of your next project operating efficiently and reliably.

REFERENCE

1) Dougan, D.S. (2003). Airflow measurement for HVAC systems – Technology comparison. Retrieved from http://www.airflowmeasurement.com/Web_Pdfs/AirflowMeasurement_Comparison.pdf

The vice president of sales and marketing for Ebtron Inc., Leonard A. Damiano is active in the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), serving as a voting member of three technical committees (Instruments and Measurements, Control Theory and Application, and Moisture Management in Buildings), two special-project committees (Standard Methods for Laboratory Airflow Measurement and Method of Test for Rating Air Terminal Unit Controls), and one research-project committee (Stability and Accuracy of VAV Box Control at Low Flows). He has contributed to ASHRAE's Fundamentals and HVAC Applications handbooks and written or co-written numerous technical articles. He also is a member of Air Movement and Control Association International and the U.S. Green Building Council.