Special: A Closer Look at Transport-Membrane-Condenser Technology

Editor's note: The Design Solutions department of the June 2010 edition of HPAC Engineering’s biannual Boiler Systems Engineering special section included a case study on transport-membrane-condenser technology. In response to reader interest, HPAC Engineering invited the authors to explain in greater detail how the technology works.

An upgrade to industrial and commercial high-pressure steam boilers, a transport-membrane-condenser (TMC) system enables the capture, recovery, and re-use of all sensible and latent waste heat, as well as water vapor from exhaust/flue gas.

Tubes made of a nanoporous ceramic membrane capture water via capillary condensation. A partial vacuum inside of each tube aids the transport of water through the tube wall.

A TMC system typically is applied in conjunction with an economizer. In a typical boiler steam loop, a TMC water-recovery unit operates in two stages to maximize its ability to recover both water and heat; thus, two separate cooling-water streams are used.

On the water side, first-stage TMC inlet water is obtained from the makeup water through a softener going to the boiler system. TMC outlet water with recovered water vapor and associated latent heat from flue gas goes to the deaerator for boiler-water makeup. Second-stage TMC inlet water comes from the deaerator system; it goes to the boiler with extra water recovered from the flue gas.

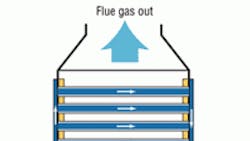

On the flue-gas side, the TMC typically is situated between the boiler exhaust and stack. However, it also can be mounted off of the boiler, in a side stream of the boiler exhaust.

The system is designed to recover most of the remaining heat in flue gas. This includes latent heat associated with water vapor, which accounts for two-thirds of the waste heat from natural-gas combustion. During this process, flue gas enters high- and low-pressure economizers. These components recover sensible heat from the flue gas to provide preheated water back to the system and cool flue gas before it enters the TMC.

Flue gas enters the TMC from the low-pressure economizer. The nanoporous-ceramic-membrane material condenses water vapor with the remaining sensible and latent heat for use as boiler feedwater, exhausting cooler, drier flue gas to the stack. The hot-water vapor extracted from the flue gas combines with incoming cold makeup water to expand and heat the water supplied to the system. The warm water is pumped out of the TMC through the low-pressure economizer, where it picks up additional heat from the flue gas on its way to the deaerator/makeup tank, shown at the top of Figure 1.

Page 2 of 2

If boiler makeup rate is less than 35 percent, an optional heat-sink component—an air heater—is recommended. This device pumps a portion of heat from the TMC back to the boiler via air, managing water temperatures in applications that return and reuse a major portion of condensate from their steam systems and, thus, do not supply sufficient cold makeup water for the TMC to reach maximum effectiveness.

The deaerator/makeup tank functions as both a holding tank and a conditioning vessel for the boiler feedwater. Hot water from the low-pressure economizer is mixed with recovered process condensate and conditioned by exposure to a small portion of process steam from the boiler to drive out any residual dissolved oxygen. The deaerated hot water then flows to the high-pressure feedwater pump, which sends it on through the high-pressure economizer and finally to the boiler. A key energy-saving factor is the reduced steam needed to maintain temperature in the deaerator because of heat added in the TMC and low-pressure economizer.

Testing shows TMC technology can increase fuel-to-steam energy efficiency by up to 15 percent (from a baseline of 80 percent) and the capture of moisture in flue gas by up to 40 percent, with the water used in the boiler without the need for further treatment.

Information prepared by Curt Bermel and Dan Willems, Gas Technology Institute, and Steve Rendos, Cannon Boiler Works Inc. Photographs and diagrams courtesy of Cannon Boiler Works Inc.

For Design Solutions author guidelines, call Scott Arnold, executive editor, at 216-931-9980, or write to him at [email protected].

About the Author

Scott Arnold

Executive Editor

Described by a colleague as "a cyborg ... requir(ing) virtually no sleep, no time off, and bland nourishment that can be consumed while at his desk" who was sent "back from the future not to terminate anyone, but with the prime directive 'to edit dry technical copy' in order to save the world at a later date," Scott Arnold joined the editorial staff of HPAC Engineering in 1999. Prior to that, he worked as an editor for daily newspapers and a specialty-publications company. He has a bachelor's degree in journalism from Kent State University.