The Refrigerant Shift in Centrifugal Chillers: From HCFCs to HFCs

Overview of the Montreal Protocol's phase-out of HCFCs

In 1987, the Montreal Protocol mandated a phase-out schedule for chlorofluorocarbons (CFCs), a family of refrigerants linked to ozone depletion. This agreement was later amended with a phase-out schedule for another class of refrigerants -- hydrochlorofluorocarbons (HCFCs). Then on Sept. 21, 2007, 20 years after the Montreal Protocol was authored, the protocol's signatories agreed to accelerate the

end of HCFCs.

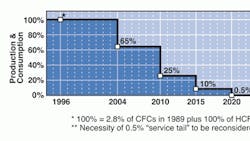

The new schedule is aggressive. In 2010, developed countries will reduce HCFC production and consumption to 25 percent of the 1989 cap, and in 2015 to 10 percent. In 2020, HCFCs can no longer be used in new equipment. The only HCFC production allowed after that is a "service tail" of 0.5 percent of the cap (Figure 1). The necessity of a "service tail" will be reconsidered in 2015, so there is no guarantee of a service supply of HCFCs past 2020.

Within many developed countries, however, the phase-out of HCFC refrigerants is proceeding faster than the 2007 accelerated schedule. The European Union ended HCFC refrigerant production and consumption in new equipment in 2001 and plans to totally cease HCFC use, including service, in 2015. The U.S. Environmental Protection Agency (EPA) adopted an accelerated schedule to end HCFC-22 production and consumption in new equipment by 2010 in the United States.

Impact of HCFC Phase-Out on Centrifugal Chillers

The early move away from HCFC refrigerants has been made possible by the development of HFC refrigerants. In centrifugal chillers, the most popular choice is HFC-134a.

Figure 2 shows the shift in market share for centrifugal-chiller refrigerants since 1990. More than 80 percent of centrifugal chillers, now being manufactured, employ HFC-134a. Moreover, all major manufacturers now offer HFC-134a centrifugal models. As a result, HFC-134a production has reached more than 200,000 metric tons annually and is increasing. In comparison, HCFC-123 production is estimated to be 4,000 to 6,000 metric tons annually and is decreasing.

The Choice of HFC-134a Refrigerant

Ever since a link was established between refrigerant chemistry and its impact on the environment, refrigerants have been evaluated by not only performance metrics, but ozone-depletion potential (ODP) and global-warming potential (GWP). After evaluating these parameters, the market has chosen HFCs over HCFCs.

Ozone-Depletion Issue

The ODP metric is the amount of degradation to the ozone layer caused by a substance compared to trichlorofluoromethane (CFC-11), which was given an ODP rating of 1.0.

The continued pressure to accelerate the HCFC phase-out is because of the ODP ratings of HCFCs. HCFC-123, for example, contains chlorine and has an ODP rating of 0.02. HFC-134a contains no chlorine and has zero ODP, indicating no affect on the ozone layer (Figure 3).

Because HFC-134a has zero ODP, accelerating its substitution for HCFCs is believed to speed up benefits to the environment. New York Times writer Keith Bradsher reported in the article Push to Fix Ozone Layer and Slow Global Warming, "The accelerated phase-out of HCFC refrigerants could speed up the healing of the ozone layer by five years."1

Global-Warming Issue

Scientists see a linkage between ozone-depleting substances (ODS) and global warming. They believe that addressing ODP also addresses global warming (also known as "climate change").

A March 2007 study, published in the Proceedings of the National Academy of Sciences, found that "the Montreal Protocol will have reduced the net global-warming-potential-weighted emissions from ODS in 2010 by five to six times the reduction target of the first commitment period of the Kyoto Protocol (2008-2012), an international effort to cut emission of carbon dioxide and other greenhouse gases."

A 2007 United Nations Environmental Program (UNEP) publication, Achievements in Stratospheric Ozone Protection, Progress Report 1987--2007, indicated, "The reduction in ODS between 1990 and 2000 has yielded a net-integrated reduction of approximately 25 billion tons of weighted global-warming gases. These significant reductions make the Montreal Protocol one of the prime contributors in the fight against global warming."

So, reducing the supply of ODS in the atmosphere also has a beneficial effect on global warming. What, then, is the impact of a refrigerant's GWP rating? To find out, we need to recognize that a refrigerant's total effect on global warming has both a "direct" effect and an "indirect" effect.

The direct effect of a refrigerant on global warming is its interaction in the atmosphere. It is represented by a GWP rating (Figure 4). GWP is a measure of how much a given mass of greenhouse gas is estimated to contribute to global warming. Carbon dioxide is the greenhouse gas used as the reference point. The GWP metric is the ratio comparing the results of emissions from one kilogram of a greenhouse gas to one kilogram of carbon dioxide over 100 years.

However, the direct effect can only occur if the refrigerant leaks out of the chiller. In daily operation, leakage is miniscule. That is because chillers manufactured today are tighter, thereby minimizing leakage, regardless of the refrigerant. Accordingly, the direct effect is very small.

The indirect effect of a refrigerant on global warming is a result of how much carbon dioxide is produced by a fossil-fuel power plant to generate electricity to run the chiller. The less efficient the chiller, the more electricity it consumes, and the more carbon dioxide is produced. The amount of electricity a chiller consumes has a significant impact on greenhouse-gas emissions. Accordingly, the indirect effect is the most important global-warming factor, comprising 95 to 98 percent of the total effect.

Proposals made at the Sept. 2007 meeting recommended the exemption of HCFC-123 from early phase-out. The claim was that HCFC-123 would produce less global warming because of its theoretical thermal-efficiency advantage of about 3 percent compared to HFC-134a, which would result in HCFC-123 chillers having better full-load efficiencies. The protocol's signatories rejected those proposals, for good reason.

Chiller efficiency is determined by mechanical efficiency, driver efficiency, heat-transfer efficiency, refrigerant efficiency, and control technologies. Though HCFC-123 theoretically has a better thermal efficiency than HFC-134a, its volumetric efficiency and heat-transfer efficiency are both worse. Although refrigerant efficiency does have an impact on chiller efficiency, it is only one factor. In general, chillers of equal efficiency can be supplied, regardless of the refrigerant used.

Based upon the actual sales of equipment for many years, there is no difference in efficiency between HCFC-123 or HFC-134a chillers purchased. This is not a surprise. It is an expected outcome because both are competitively sold to meet a specified energy performance demanded in a particular project. Hence, the indirect effect of a refrigerant on global warming is essentially the same for all centrifugal chillers, regardless of the refrigerants used.

For all these reasons, the GWP ratings of the various refrigerants play a minimal role in climate change. In theory, the differences look large but, in practice, they have little impact on global warming.

Conclusion

On Sept. 21, 2007, the Montreal Protocol signatories again showed their commitment to treating ozone depletion as the environmental problem at the "head of the line" for international action. They accelerated the phase-out of HCFCs. The shift away from the use of HCFC-123 in centrifugal chillers is being made possible because the alternative -- HFC-134a -- addresses ozone depletion and global warming.

New centrifugal chillers have a 30-year life span. This fact, coupled with the accelerated phase-out of HCFC-123, adds a high degree of uncertainty in purchasing a new HCFC-123 chiller. More than 80 percent of centrifugal chillers manufactured today are successfully using HFC-134a. Consequently, all major manufacturers offer HFC-134a centrifugal chillers in their product line, supporting the use of HFC-134a as a proven alternative to HCFC-123 in centrifugal-chiller specifications today and in the future.

References

1. Bradsher, Keith. "Push to Fix Ozone Layer and Slow Global Warming." New York Times 03 15 2007 1-3. 0529 2007. http://www.nytimes.com/2007/03/15/business/worldbusiness/15warming.html