Fan-Efficiency Updates in Model Energy Codes and Standards

By Michael Ivanovich, AMCA International, Armin Hauer, ebm-papst, and Christian Taber, Big Ass Fans

Some important changes related to fans have been made or are coming to model energy codes and standards. Among them: a new fan-efficiency metric, new requirements for reporting ceiling-fan power, updated requirements for fan-motor selection, and an alternative to the requirement for a vestibule in some climate zones and buildings. This article summarizes those changes.

New Metric and Scope

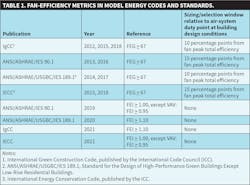

Starting with the 2019 edition of ANSI/ASHRAE/IES 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings, fan-efficiency provisions in model energy codes and standards are transitioning from fan efficiency grade (FEG) to the new fan energy index (FEI). Table 1 shows how FEG and FEI have been referenced in model energy codes and standards since 2012. FEI-based provisions will make their way into state building codes through normal revision cycles. Some states adopting the 2016 edition of ANSI/ASHRAE/IES 90.1 or the 2018 edition of the IECC may leapfrog to FEI.

Defined in ANSI/AMCA Standard 208-18, Calculation of the Fan Energy Index, FEI, like FEG, is calculated from data taken from laboratory tests conducted for rating. Manufacturers calculate FEI ratings; designers and contractors only have to ensure rated fans meet energy-code and project requirements.

FEI was developed by Air Movement and Control Association (AMCA) International and other industry stakeholders in response to a yet-to-be-concluded 2011 rulemaking for commercial and industrial fans and blowers initiated by the U.S. Department of Energy (DOE). It offers numerous benefits compared with FEG, which the DOE intimated in a 2013 framework document would not work for a federal efficiency standard. Among them:

• FEI is easier to enforce because, with FEG, there is a “sizing/selection window” that must be applied by designers and fact-checked by code officials;

• FEI ratings include power losses from motors and drives based on manufacturers’ wire-to-air tests or, in the case of “bare-shaft” fans, default motor and drive losses;

• FEI covers part-load operation, so specifying FEI compliance at a minimum threshold for 100-percent airflow of a variable-air-volume (VAV) system results in compliant FEI ratings at lower airflows;

• Because FEI works for low-pressure fans, the exception for power roof ventilators can be eliminated;

• FEI works for fans rated using static pressure, not just total pressure;

• Fan electrical power (FEP), which is determined as part of an FEI calculation, can be used in energy-efficiency and life-cycle-cost analyses;

• FEI ratings are all certified by AMCA.

Other Fan-Efficiency Changes

As of 2019, efficiency provisions extended to fans with lower power ratings, with the list of exceptions refined. Table 2 (above) summarizes scoping changes. Note that for VAV systems, fans can have a slightly lower FEI rating. This encourages the use of electronic fan-speed controls for load matching.

A fan-power comparison at strictly full speed potentially would favor a fixed-speed fan.

Fan-Motor Selections

ANSI/ASHRAE/IES 90.1-2019 and the 2021 IECC lift restrictions on fan-motor sizing without weakening efficiency requirements by increasing the number of design options for load-matching variable-speed fan motors. Also, they accommodate new motor and drive technologies and simplify motor-selection criteria for fans.

Essentially, the new sections exempt fans from nameplate horsepower requirements if the fans match performance to load with variable-speed drives. This saves fan energy while leaving in place sizing requirements for all fan motors operated directly online.

The section “Motor Nameplate Horsepower” intends to limit motor loss at part load. It assumes that in all cases an oversized fan motor consumes more power than a motor that has a nameplate horsepower closer to the required fan shaft power. In practice, this is not always the case. Consider:

• Larger regulated motors must have higher nameplate efficiencies than smaller motors. However, the efficiency loss of motors used with variable-speed drives is less than that of motors used without variable-speed drives at a given part load. Therefore, limiting motor-nameplate horsepower makes no sense for variable-speed-drive applications. The new section in ANSI/ASHRAE/IES 90.1-2019 relieves designers, installers, and building officials of this burden;

• Some types of motors, including multispeed motors and air-over motors closely coupled with fan impellers, are exempt from government efficiency regulation. In these cases, motor output power and motor efficiency are not verifiable per the 2018 IECC, so the existing motor-horsepower criterion is unenforceable. Addendum CE eliminates sizing restrictions for all fans used with variable-speed drives;

• There is no DOE test procedure for super-premium-efficiency motors, such as electronically commutated permanent-magnet, switched-reluctance, and other inverter-only motors. In many cases, these motors are rated by motor electrical input power and not necessarily shaft output power. Further, they are not available in small increments of rated power, which often prevents compliance with the 2018 IECC. ANSI/ASHRAE/IES 90.1-2019 and the 2021 IECC exempt these fan motors, so designers, installers, and building officials need not worry about nameplate horsepower requirements.

Large-Diameter Ceiling Fans

In ANSI/ASHRAE/IES 90.1-2019 and the 2021 IECC, new language for large-diameter ceiling fans was added. Because of the way blade-span measurement and rounding is defined in the DOE test procedure (10 CFR 430.2 and 10 CFR Appendix U to Subpart B of Part 430) — ceiling-fan blade span (blade-tip diameter) is determined using “the lateral distance from the center of the axis of rotation of the fan blades to the furthest fan blade edge from the center of the axis of rotation” and rounded to the nearest inch — 84.5 in. is the minimum diameter for a large-diameter ceiling fan. This ensures that ceiling fans will be in the same product classes in ANSI/ASHRAE/IES 90.1 and U.S. federal regulations.

Section 6.4.1 of ANSI/ASHRAE/IES 90.1 requires that blade span (blade-tip diameter), airflow at maximum speed, and power consumption at maximum speed be determined using either 10 CFR Appendix U or ANSI/AMCA Standard 230. The provided data must have been determined by an independent laboratory, included in a database published by the DOE, or certified under a program meeting the requirements of Section 6.4.1.5. For projects in the United States, 10 CFR Appendix U must be used and the fan must be registered in the DOE database. For projects outside the United States, ANSI/AMCA Standard 230 and the AMCA Certified Ratings Program could be used to satisfy this requirement.

Air Curtains

With the publication of ANSI/ASHRAE/IES 90.1-2019, air curtains are an approved alternative to vestibules in certain climate zones and buildings of certain sizes in all model energy codes and standards. They have been allowed as an alternative to vestibules in the IECC and ANSI/ASHRAE/USGBC/IES 189.1 since 2015 and the IgCC since 2012.

In Section 5.4.3.4 of ANSI/ASHRAE/IES 90.1-2019, exceptions 10 and 11 allow self-closing doors in buildings in climate zones 0, 3, and 4 and in buildings 15 or fewer stories in climate zones 5-8 to have an air curtain instead of a vestibule. In either case, Section 10.4.5 requires that air curtains:

• Be tested in accordance with ANSI/AMCA Standard 220, Laboratory Methods of Testing Air Curtain Units for Aerodynamic Performance Rating, or ISO 27327-1, Fans — Air Curtain Units — Part 1: Laboratory Methods of Testing for Aerodynamic Performance Rating;

• Be installed and commissioned in accordance with the manufacturer’s instructions;

• Have a jet velocity of at least 6.6 fps (2.0 m/s) at 6.0 in. (15 cm) above the floor and a direction not less than 20 degrees toward the opening.

The allowance of air curtains as an alternative to vestibules is supported by research conducted by Concordia University in Montreal and funded by AMCA International, Berner International, Mars Air Systems, and Powered Aire. The research included computational-fluid-dynamics modeling verified by laboratory testing.

Conclusion

FEI is replacing FEG in model energy codes and standards, starting with the 2019 edition of ANSI/ASHRAE/IES 90.1. FEI saves more energy than FEG and is easier to use by designers and easier to enforce by code officials. AMCA International has many educational resources at www.amca.org/fei to help the industry learn how to apply FEI and obtain FEI ratings through certified manufacturer sizing/selection software.

At the same time, provisions for selecting motors for fans and reporting requirements for large-diameter ceiling fans have been added to ANSI/ASHRAE/IES 90.1 and the 2021 edition of the IECC.

Altogether, these provisions will improve fan efficiency and make life easier for system designers and code officials.

References

Ivanovich, M., Wroblewski, R., & Boldt, J. (2019, September). Applying fan energy index (FEI) in regulations and applications. Paper presented at International Conference on Energy Efficiency in Motor Systems, Tokyo. Available at www.amca.org/educate.

Johnson, D. (2019). Air curtains: A proven energy-saving alternative. AMCA inmotion, pp. 14-20. Available at http://bit.ly/AMCAinmotion2019.