Fundamental Analysis Methods for Heating and Cooling Systems

Modern networked controls, smart interval meters, and systems integration make available a rich set of data that can be used to improve a building’s operational efficiency. Meanwhile, myriad tools and methods for analyzing that data are available. With so many options, building managers and operators often are left wondering where to start. What data are required for proactive energy management? Which analyses should be performed, and how frequently?

The new “Energy Information Handbook: Applications for Energy-Efficient Building Operations”1 targets users with little or no experience analyzing data and monitoring performance. It includes 18 methods of analyzing utility, interval-meter, and submetered energy and control-system data, as well as overviews of manual and automated fault detection and diagnostics (FDD).

This article provides an overview of the content of the handbook and the subset of analysis methods applicable to the operation of heating and cooling systems. The discussion focuses on loading histograms, efficiency analysis, and FDD. To conclude, a summary of complementary methods, such as load profiling and energy signatures, is presented, with a discussion of energy-saving benefits.

Handbook Design

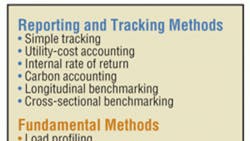

The handbook is broken into five chapters—Introduction, Reporting and Tracking Methods, Fundamental Methods, Advanced Methods, Fault Detection and Diagnostics—and an appendix.

Reporting and Tracking Methods includes approaches to gauging financial, energy, and carbon performance. The approaches can be applied to specific building systems; however, they most commonly are used at the site or portfolio level. They can use utility billing information and may not require interval-meter data or sensor time-series data.

The fundamental methods include system-specific and whole-building analyses and require relatively more user expertise than the reporting and tracking methods and the advanced methods (Figure 1). The analyses tend to require interval-meter data or other time-series data, such as temperature. This core set of analyses is used to reveal energy waste and opportunities for operational-efficiency improvements and includes several methods applying specifically to heating and cooling systems.

Each of the advanced methods requires interval-meter data and (in best-practice applications) a baseline model that can quantify expected or forecasted energy use robustly. Although they are the most sophisticated and computationally intensive methods in the handbook, the advanced methods involve less manual inspection than the fundamental methods and, thus, require minimal expertise for interpretation. The FDD chapter and appendix contain more advanced concepts, technical details, and resources.

The handbook presents each analysis method beginning with a summary of purpose, applicable building systems, frequency of use, target audience, and underlying technical approach. This is followed by an overview of relevant commercial tools and step-by-step calculations. The remaining content is dedicated to interpretation and application examples.

Loading Histograms

Purpose. Loading histograms are used to evaluate whether HVAC equipment is sized and staged properly, given the operated condition of a building. They are useful in identifying potential retrofit solutions and optimizing control of multiunit staging (Figure 2).

Technical approach. Group system-load measurements into “bins,” or ranges, and count the number of hours the system operated within each. Construct a bar chart, with load plotted on the x-axis and the number of hours at each load plotted on the y-axis (Figure 3). Then, compare the distribution of operational hours at each load to manufacturer load ratings and equipment staging sequences.

Interpretation. Equipment is sized according to expected building loads and a margin of safety. If a histogram shows frequent operation at loads far below rated capacity, downsizing may be appropriate. For example, a chiller’s efficiency “sweet spot” typically is 70 percent to 80 percent of full load. Boilers, on the other hand, often cycle at loads below 20 percent, introducing energy waste and part wear.

Technical details. Sizing systems relative to actual building loads affects operational efficiency. Typically, system efficiency decreases as load falls below maximum rated capacity to part-load conditions. Because most systems do not operate at full capacity for the majority of annual run-hours, parallel units often are used to match capacity to load and improve efficiency.

Figure 4 shows a loading histogram for a chiller-retrofit analysis.

Heating and Cooling Efficiency

Purpose. Heating and cooling systems comprise a significant portion of commercial-building load. The efficiency of these systems commonly degrades because of (1) a lack of proper maintenance and (2) controls complexity, which can obscure energy waste. Operational efficiencies can be verified according to manufacturer performance specifications (Figure 5).

Technical approach. Using interval data, calculate the amount of heating or cooling produced and the energy required to produce it, and generate a plot, with load on the x-axis and efficiency on the y-axis (Figure 6). Compare performance to specifications, and use the plots to determine if efficiency changes with loading as expected. Some systems operate more efficiently at part load and others at full load. Changes or excessive scatter in an x-y plot may be indicative of control or sequencing problems.

Page 2 of 3

Interpretation. Coefficient of performance (COP) is a unitless efficiency metric, with bigger numbers reflecting better performance. Kilowatts per ton is an inverse efficiency metric—the smaller the number, the better the performance. For chiller plants (including pumps and tower fans), a COP below 3.5 or a kilowatts-per-ton reading above 1.0 indicates relatively poor performance. Boiler efficiency tends to range from 80 percent to 83 percent for conventional units, 84 percent to 88 percent for efficient units, and 89 percent and above for high-efficiency condensing units. These are broad rules of thumb influenced by equipment type and age, climate, operating conditions, and system/equipment-analysis boundaries.

Technical details. The load produced in heating and cooling systems is calculated from a flow measurement, a temperature delta between system supply and return, and unit conversion factors. Boiler loads are computed from measures of water flow, while furnace loads are computed from measures of airflow. Similarly, water-cooled-chiller loads are computed from measures of water flow, while direct-expansion-chiller loads are computed from measures of airflow.

Figure 7 shows an example of chiller-efficiency analysis.

Fault Detection and Diagnostics

Purpose. The primary objective of FDD is to detect system-equipment faults early and identify their causes, preventing energy waste, system damage, and/or loss of service. FDD can be performed “manually” through visual inspection of charts and trends or fully automated. An example of manual FDD is presented in Figure 8.

Automated FDD. Automated algorithms use measured time-series data and set-up data describing equipment and system characteristics (e.g., setpoints and type of control) to generate actionable information. Automation streamlines the FDD process and enables continuous performance tracking. Many methods of automated FDD exist, but rule-based methods, broadly classified as first-principle qualitative models, are most commonly employed in commercial FDD tools. With this approach, qualitative relationships, or “rules,” are derived from knowledge of underlying system operation. Figures 9 and 10 illustrate the output of two such rule-based tools for outside-air economizers.

Complementary Methods

Load profiling, baselines, and energy signatures also are included in “Energy Information Handbook” and can be used to identify efficiency opportunities for heating and cooling systems.

Load profiling. Plots of 24-hr or longer periods of interval-meter data are inspected on a daily or weekly basis to understand the amount of energy used at given times and days of the week. Visible changes in load shape, or “profile,” are readily identified as periods of either energy waste or energy reduction (Figure 11).

Baselines. Energy-consumption baselines characterize energy usage based on historic data, such as metered energy use and weather conditions. Typically, they are used as the basis of analyses such as benchmarking, automated energy-anomaly detection, and quantification of total or cumulative energy savings. Simple baselines normalize total energy use by key influencing factors, such as square footage, number of days in the period, or degree-days, and commonly are used to benchmark energy use over time or relative to a set of similar buildings. Energy-savings determination and anomaly detection typically require model-based baselines providing a mathematical relationship between energy use and the variables that drive energy use, such as time of day and air temperature. Regression models are the most commonly used baselines.

Page 3 of 3

Energy signatures. Plots of energy use and outdoor-air temperature are used to monitor the performance of temperature-dependent loads, such as whole-building gas and electricity. The data points in an energy signature should follow orderly lines reflecting consistent behavior; highly scattered points should be investigated as possible indicators of inefficiency. As shown in Figure 12, loads at which energy use does not change with temperature and the rate at which load changes with temperature (i.e., the heating or cooling slope) also are useful in identifying potential efficiency improvements.

Conclusion

The analysis methods in “Energy Information Handbook” are intended to be applied collectively to achieve low-energy building operations. They span several levels of analysis from portfolio to whole-building and system investigations and, used in combination, can generate multiple insights into a common set of “root” aspects of energy performance.

The energy savings achievable through continuous performance monitoring and analysis depend on several factors, including how bad the building performed before tracking was initiated, the depth of metering and availability of measured data, the level of engagement of the operator or facility manager, and the operator’s or facility manager’s ability to take action once problems are identified. Research on the costs and benefits of commissioning has shown that existing buildings waste 16 percent on average because of inefficient operations, much of which can be remedied with low/no-cost solutions.5

The system-level and FDD analysis methods presented in “Energy Information Handbook” can expose many operational inefficiencies identified during the commissioning process. Monitoring-based commissioning, or the use of permanent metering for continuous performance analyses, is documented to save 9 percent in energy use and increase persistence of energy savings over time.6 Moreover, performance analyses applied at the whole-building level can reveal inefficiencies in heating and cooling systems, lighting and plug loads, and loads that may not be individually submetered. Case studies have shown 5- to 25-percent site or portfolio energy savings, quick payback, high return on investment, and persistent low-energy performance in cases in which an organization has implemented a continuous energy-monitoring and analysis program in combination with enabling software tools and an accountable staff.7,8,9,10

Acknowledgements

The authors thank George Hernandez of the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Building Technologies Program, for his support in developing “Energy Information Handbook” and Srinivas Katipamula of Pacific Northwest National Laboratory for co-authoring the FDD chapter.

This work was supported by the assistant secretary for Energy Efficiency and Renewable Energy, Building Technologies Program, of the U.S. Department of Energy under Contract DE-AC02-05CH11231.

Disclaimer

This article is an account of work sponsored by the U.S. government. While the article is believed to contain correct information, neither the U.S. government nor any agency thereof, nor The Regents of the University of California, nor any of their employees makes any warranty, express or implied, or assumes any legal responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by its trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the U.S. government or any agency thereof or The Regents of the University of California. The views and opinions of authors expressed herein do not necessarily state or reflect those of the U.S. government or any agency thereof or The Regents of the University of California.

References

1) Granderson, J., Piette, M.A., Rosenblum, B., & Hu, L. (2011). Energy information handbook: Applications for energy-efficient building operations. LBNL-5272E. Available at http://eis.lbl.gov

2) Piette, M.A., Carter, G., Meyers, S., Sezgen, O., & Selkowitz, S. (1997). Model-based chiller tracking for performance assurance at a university building. LBNL Report No. 40781.

3) Piette, M.A., et al. (1998). Development and testing of an information and diagnostic system for large commercial buildings. LBNL Report No. 41926. Available at http://imds.lbl.gov/pubs/ace3/aceee.html

4) Mazzarella, L., & Liziero, M. (Eds.). Neumann, C., & Jacob, D. (2009). Description of European prototype tool for evaluation of building performance and the national tools. Available at http://www.buildingeq-online.net/fileadmin/user_upload/Results/BEQ_report_WP5_090823.pdf

5) Mills, E. (2009). Building commissioning: A golden opportunity for reducing energy costs and greenhouse gas emissions. LBNL Report No. 3645-E. Available at http://cx.lbl.gov/documents/2009-assessment/LBNL-Cx-Cost-Benefit.pdf

6) Mills, E., & Mathew, P. (2009). Monitoring-based commissioning: Benchmarking analysis of 24 UC/CSU/IOU projects. LBNL Report No. 1972-E. Available at http://eetd.lbl.gov/emills/pubs/pdf/MBCx-LBNL.pdf

7) Capehart, B., & Middlekoop, T. (Eds.). (2011). Handbook of web based energy information and control systems. Lilburn, GA: Fairmont Press.

8) Granderson, J., Piette, M.A., & Ghatikar, G. (2010, June). Building energy information systems: User case studies. Energy Efficiency Journal, pp. 17-30.

9) Motegi, N., Piette, M.A., Kinney, S., & Dewey, J. (2003). Case studies of energy information systems and related technology: Operational practices, costs, and benefits. LBNL Report No. 53406. Available at http://eetd.lbl.gov/BT/hpcbs/pubs/E5P22T1e_LBNL-53406.pdf

10) Accenture. (2011). Energy-smart buildings: Demonstrating how information technology can cut energy use and costs of real estate portfolios. Available at http://www.scribd.com/doc/67751676/Energy-Smart-Buildings-Whitepaper-Microsoft-s-tudy

Jessica Granderson, PhD, is a research scientist and the deputy of research programs for the Building Technologies Department of Lawrence Berkeley National Laboratory (LBNL). She has a doctorate in mechanical engineering from the University of California, Berkeley (UC Berkeley) and a background in intelligent lighting controls and whole-building energy-performance monitoring and diagnostics. Mary Ann Piette is the head of the Building Technologies Department of LBNL and director of the LBNL-led Demand Response Research Center. She has a bachelor’s degree in physical science and a master’s degree in mechanical engineering from UC Berkeley and a licence in building-services engineering from Chalmers University of Technology. Benjamin Rosenblum is a research associate in the Building Technologies Department of LBNL. He has a master-of-architecture degree from the Yale School of Architecture and a master-of-science degree in architecture, with a concentration in building science, from UC Berkeley and a background in sustainable building design and whole-building energy-performance monitoring. Dan Harris, PE, is a senior project manager for the New Buildings Institute working primarily on projects related to energy metering, measurement and verification, and system integration. He holds bachelor’s and master’s degrees in mechanical engineering of control systems. A senior at the University of Toronto pursuing a bachelor’s degree in engineering science, with a major in energy systems, R. Lily Hu was an undergraduate researcher at LBNL during the summer of 2011. Prior to that, she worked as a research assistant at the University of Calgary and the University of Birmingham.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].