The role of e-commerce in the retail world has shifted since the SARS-COV-2 coronavirus hit our shores. During the COVID-19 global pandemic, consumers turned to online shopping — and Amazon continues to carve out a big piece of the e-commerce pie.

To fill all those orders, especially as the holiday shopping season approached, the retail giant this year has been building huge fulfillment centers at an astounding pace across the U.S., as well as 1,000 small delivery hubs, to make delivery more efficient. In a July call to discuss its second-quarter results, Amazon officials said the company would increase fulfillment center square footage by 50 percent in 2020. Second-quarter net sales (April through June) increased 40 percent, to $88.9 billion, from the same period in 2019. Third-quarter sales jumped 37 percent.

“The company has been pouring money into building and leasing distribution center space for years, but appears to have pushed up its timeline in 2020,” reports The Real Deal. “Since March, Amazon will have leased about 11 million square feet of distribution centers and warehouses in the Chicago area alone.”

In fact, Amazon accelerated its growth in fulfillment centers and delivery, which was originally planned for 2021, to satisfy COVID-19 demand. “Beyond the pandemic, the warehouse, logistics and last-mile center space is necessary to meet goals of one-day shipping,” The Real Deal notes.

Amazon’s capital expenditures rose 65 percent in the second quarter to $9.4 billion. “Once these buildings open, they are a headwind to profitability,” Amazon CFO Brian Olsavsky told the publication.

Fulfillment centers act as major hubs for Amazon, where merchandise is shipped and stored until picked for an order. In addition to traditional warehousing centers, Amazon also has robotic centers where every piece of information is digitized so robots can bring ordered material to the workers. You can view a video of what goes in a fulfillment center at https://bit.ly/33g21zD.

“Around 800,000 sq. ft. in size, sortable fulfillment centers can employ more than 1,500 full-time associates,” notes Amazon on its website. “In these buildings, Amazon employees pick, pack and ship customer orders such as books, toys, and housewares. Thanks to the innovations of Amazon Robotics, associates often work alongside robots, allowing them to learn new skills and helping to create a more efficient process to meet customer demand.”

The company also has what it calls nonsortable fulfillment centers that stock bulky or larger-sized customer items such as patio furniture, outdoor equipment, or rugs. These structures range from 600,000 to 1 million sq. ft.

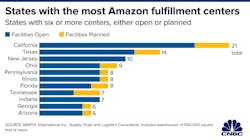

U.S. fulfillment centers under construction or opened in 2020 and 2021 are located in 16 states: Arkansas, California, Florida, Idaho, Illinois, Iowa, Kansas, Mississippi, Missouri, Nebraska, North Dakota, Ohio, Pennsylvania, Tennessee, Texas, and Utah.

Amazon combines in-house engineering personnel with engineering firms from across the country to design the MEP systems for these behemoth structures — firms such as Jordan & Skala Engineers, Kraemer Consulting Engineers, and Rock Brook Consulting Group. To see how these massive structures are built, view the video at https://bit.ly/3l6UYiS.

Sustainability Goals

In 2019, Amazon and Global Optimism co-founded The Climate Pledge, a commitment to achieve net-zero carbon by 2040 — a decade ahead of the Paris Agreement’s goal of 2050. Since then, a growing list of major companies have joined The Climate Pledge: Best Buy, Henkel, Infosys, McKinstry, Mercedes-Benz, Oak View Group, Real Betis, Reckitt Benckiser, Schneider Electric, Siemens, Signify and Verizon.

Signatories to The Climate Pledge have agreed to:

• Measure and report greenhouse gas emissions on a regular basis;

• Implement decarbonization strategies in line with the Paris Agreement through real business changes and innovations, including efficiency improvements, renewable energy, materials reductions, and other carbon emission elimination strategies;

• Neutralize any remaining emissions with additional, quantifiable, real, permanent, and socially-beneficial offsets to achieve net-zero annual carbon emissions by 2040.

“Buildings account for 40 percent of energy use in the United States, 36 percent globally,” said Dean Allen, CEO of McKinstry, a Seattle-based construction engineering firm. “Emerging, complex building technologies are unlocking the potential to radically reduce carbon emissions and operate buildings with startling efficiency. It will take working together across industries to deploy these technologies and decarbonize the global building stock and dramatically improve energy efficiency,” predicted Allen.

Joe Kaeser, president and CEO of Siemens AG, added: “Climate Change is one of humanity’s greatest challenges of our time. Businesses need to lead the way towards accelerated decarbonization.”

This past June, Amazon announced The Climate Pledge Fund to support the development of sustainable and decarbonizing technologies and services that will enable Amazon and other companies to meet the goals set by The Climate Pledge. The investment program has an initial $2 billion in funding. Amazon announced the fund’s first recipients in September:

• CarbonCure Technologies. It has commercialized a portfolio of carbon removal technologies that consume carbon dioxide in concrete during production, permanently sequestering CO2 and enabling the reduction of cement content in mixes without impacting concrete performance. Amazon is working to lower the embodied carbon footprint of its facilities by using this concrete in many of its new buildings, including HQ2 in Virginia;

• Pachama. The climate technology company verifies the impact of carbon capture in the world’s forests, allowing organizations and individuals to compensate for their emissions with confidence by supporting reforestation and forest conservation projects. Pachama will help Amazon monitor and evaluate such nature-based solutions;

• Redwood Materials. The company develops and commercializes a full process and suite of technologies for recycling end-of-life, lithium-ion batteries and e-waste into high value metals and chemicals. It will help Amazon properly recycle electric vehicle batteries and reuse their components;

• Rivian. As part of The Climate Pledge announcement in 2019, Amazon revealed it had purchased 100,000 EVs from Rivian, with plans to have 10,000 of the new electric vehicles on the road as early as 2022, and all 100,000 vehicles in use by 2030;

• Turntide Technologies. The company’s motors reduce energy use by 64 percent on average by optimizing efficiency and control without using expensive materials or rare earth minerals. Amazon is piloting Turntide’s motors in a number of its buildings and the results so far have demonstrated significantly reduced electricity usage, the company says.

To fulfill its global Climate Pledge obligations, Amazon also announced in May that new, utility-scale solar projects will help it power operations in the United States, China and Australia — two in Ohio, one in Virginia, one in China and one in Australia. To date, Amazon has announced 31 utility-scale wind and solar renewable energy projects and 60 solar rooftops on fulfillment centers and sort centers around the globe.

Together, these projects totaling over 2,900 MW of capacity will deliver more than 7.6 million MWh of renewable energy annually, enough to power 680,000 U.S. homes.

Of course, the company’s sustainability concerns certainly predate the Pledge. In 2015, Amazon developed a district heating approach for its Seattle headquarters — waste heat from the neighboring Westin Building Exchange, which houses more than 250 telecom and Internet companies. Instead of venting its heat into the air, the Westin uses underground piping to a central plant in Amazon’s Doppler tower.

At about 65° F, the arriving water isn’t quite hot enough to warm offices, so it’s run through five heat-reclaiming chillers that concentrate the heat into a smaller volume of water, raising the temperature to about 130° F. Hidden radiant coils circulate the heat throughout the campus.

##########

The author is a contributing writer to HPAC Engineering magazine, and the former editor of Plumbing & Mechanical magazine. Faloon has more than 20 years’ experience in the plumbing and heating industry and B2B publishing. A native of Michigan’s northern Lower Peninsula, she is a journalism graduate of Michigan State University.

About the Author

Kelly L. Faloon

Contributing Writer/Editor

Faloon spent 3 1/2 years at Supply House Times before joining the Plumbing & Mechanical staff in 2001. Previously, she spent nearly 10 years at CCH/Wolters Kluwer, a publishing firm specializing in business and tax law, where she wore many hats — proofreader, writer/editor for a daily tax publication, and Internal Revenue Code editor.

A native of Michigan’s northern Lower Peninsula, Faloon is a journalism graduate of Michigan State University. You can reach her at [email protected].