Earlier this year, I wrote about the development of a new cooling system by researchers at the National University of Singapore that utilizes neither mechanical compression nor chemical refrigerants. That article, incidentally, resulted in nearly a dozen email inquiries seeking more information, including several from large HVAC manufacturers. I referred all to Dr. Ernest Chua, the principal researcher in Singapore.

Now comes word of another breakthrough in cooling technology, this one at an address much closer to home. Researchers at the Ames Laboratory, a U.S. Department of Energy (DOE) facility operated by Iowa State University of Science and Technology in Ames, IA, have designed and built a solid-state system capable of cooling to refrigeration-level temperatures. Like the system developed in Singapore, it also requires no mechanical refrigeration and utilizes circulating water as the heat transfer medium.

The system relies on magnetic refrigeration, a technology based on the magneto-caloric (MCE) effect. In this magneto thermodynamic phenomena, certain materials will change temperature when exposed to a change in the strength of a magnetic field. Similar to the Carnot refrigeration cycle – in which changes in pressure result in varying temperatures – in the magneto thermodynamic process, the pressures are replaced by magnetic field strength.

Working magnetic refrigeration systems actually date back to 1933, when an MCE device reached cryogenic temperatures. In 1997, the first near-room-temperature magnetic refrigerator was demonstrated at the Ames Laboratory. In the advanced model system most recently designed and built there, small quantities of gadolinium (Gd), a rare earth metal, are used as the magnetocaloric material.

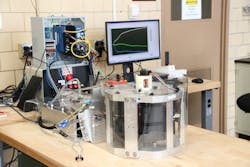

Known as CaloriSMART – Small Modular Advanced Research-scale Test-station – the system demonstrated sustained power of approximately 10 W., with a 27 deg F. (15 deg C.) temperature differential. “Despite predictions we would fail because of anticipated inefficiencies and losses, we always believed it would work," said CaloriSMART project director Vitalij Pecharsky, a professor in ISU's Dept. of Materials Science and Engineering. "But we were pleasantly surprised by just how well it worked. It’s a remarkable system and it performs exceptionally well. Magnetic refrigeration near room temperature has been broadly researched for 20 years, but this is one of the best systems that has been developed.”

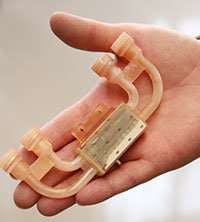

The project scientist who headed the design team, Julie Slaughter, used 3D printing (one of my "5 HVACR Trends to Look for in 2018" last December) to manufacture the heart of the system, the manifold. The entire system took approximately five months to build. CaloriSMART is an initiative of CaloriCool, the Caloric Materials Consortium at Ames, part of the Energy Materials Network which is sponsored by the DOE’s Office of Energy Efficiency and Renewable Energy through its Advanced Manufacturing Office.

According to the Ames team, MCE is just the beginning, with future upgrades of the system planned to allow it to work with elastocaloric materials (solids capable of stress-induced reversible phase transformations during which latent heat is released or absorbed) and electrocaloric materials. According to CaloriCool, they are dielectric materials that will, when an electric field is applied to them, induce a change in the polarization and, consequently, a change in the entropy and temperature in the material. This all sounds pretty cool to me. Stay tuned...

A regular contributor to HPAC Engineering and a member of its editorial advisory board, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability. He can be reached at [email protected].

About the Author

Larry Clark

A member of HPAC Engineering’s Editorial Advisory Board, Lawrence (Larry) Clark, QCxP, GGP, LEED AP+, is principal of Sustainable Performance Solutions LLC, a South Florida-based engineering firm focused on energy and sustainability consulting. He has more than two dozen published articles on HVAC- and energy-related topics to his credit and frequently lectures on green-building best practices, central-energy-plant optimization, and demand-controlled ventilation.