HVAC technicians are (or should be) very familiar with the revised refrigerant management requirements that took effect on January 1st of this year. Those requirements, contained in Section 608 of the Clean Air Act, added substitute refrigerants – including hydrofluorocarbons (HFCs) – to the ozone depleting substances (ODS) already restricted for sale to certified technicians (refrigerants such as ammonia, that are exempt from the venting prohibition, are also exempt from the sales restriction). Even more significant was the imposition of new reporting/record-keeping requirements for equipment containing 5 to 50 pounds of refrigerant.

Technicians must now document the location, date, and type of refrigerant recovered for equipment that has reached its end-of-life, and the monthly quantities of such recovered refrigerant, by type. They must also report the quantity of refrigerant, again by type, that was reclaimed or destroyed, and when and by whom it was done.

According to DRAWDOWN, the nonprofit information clearinghouse on global warming, 90 percent of refrigerant emissions occur at the equipment’s end-of-life. Not surprisingly, older equipment leaks more often than does new equipment, and much of the uncontrolled refrigerant emissions are caused by human error. The authors concluded that 87 percent of the refrigerants that are likely to be released over the next 30 years will be equivalent to 89.7 billion metric tons of CO2 equivalent (mtCO2e)

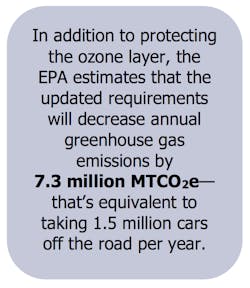

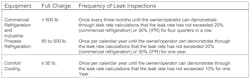

In addition to the new requirements for certified technicians that are now in effect, the EPA also added new leak inspection and verification requirements that go into effect on January 1, 2019. These revisions require leak inspections for equipment that have exceeded certain specified leak rates for HFCs, as well as for the ODS that have been regulated for more than 20 years:

An initial verification test must be performed before any refrigerant may be added, and a follow-up test must be performed after the equipment has been restored to normal operating conditions. Leak testing must be performed by EPA-certified technicians using appropriate detectors. One option to hand-held detectors is the use of automatic leak detection (ALD). Refrigerant ALD is, of course, not new. Mechanical room refrigerant leak detection in accordance with ASHRAE Standard 15 has been in place since the 1990s, and is often integrated into existing building automation systems.

My last update on refrigerants in 2015 closed by stating that the type of refrigerant doesn’t matter if the equipment doesn’t leak.

And, if it doesn’t leak, the verification and record-keeping requirements get a whole lot easier!

A regular contributor to HPAC Engineering and a member of its editorial advisory board, the author is a principal at Sustainable Performance Solutions LLC, a south Florida-based engineering firm focusing on energy and sustainability.

About the Author

Larry Clark

A member of HPAC Engineering’s Editorial Advisory Board, Lawrence (Larry) Clark, QCxP, GGP, LEED AP+, is principal of Sustainable Performance Solutions LLC, a South Florida-based engineering firm focused on energy and sustainability consulting. He has more than two dozen published articles on HVAC- and energy-related topics to his credit and frequently lectures on green-building best practices, central-energy-plant optimization, and demand-controlled ventilation.