Thermal Dynamic Efficiency in Damper Selection

By RACHEL LARIMORE, Application engineer, Ruskin, Grandview, MO

Thermally efficient dampers are used in air openings of buildings to control and direct airflow. This function ensures proper operation of heating, ventilation and air conditioning (HVAC) systems and minimizes potential heat loss to improve overall building efficiency.

In application, thermally efficient dampers can allow airflow between interior spaces but are primarily used in exterior outdoor openings. Given the wide range of applications, dampers can be designed to fit in openings as small as 6 x 6 in. or as large as 12 x 12 ft and beyond, using multi-section assemblies.

This type of damper can be applied in many different environments, but they are especially useful in extreme hot and cold ambient conditions, with damper models available for ambient temperatures ranging from -70°F (-57°C) to 200°F (93°C).

In cold climates like Canada’s, for example, thermally efficient dampers help reduce heating costs. In southwest U.S. locales like Arizona and California, they can help cut cooling costs. Typical applications vary from large area freezers in food storage facilities to warehouses, laboratories or any space requiring a steady temperature at all times. Applications can also include data centers, commercial buildings and industrial or manufacturing facilities desiring tight temperature control.

Configuration flexibility to match application needs

Installing thermally efficient dampers typically involves flange mounting the damper into an outside air opening. To improve thermal efficiency and lower the heat transfer, all sides of the damper’s extruded aluminum frame should be thermally broken in two locations. These breaks isolate each interior section against thermal conductivity.

Attachment to duct work is accomplished through a T-flange. Other flanges and damper actuators can be installed to meet the requirements of different openings. Various mounting configurations provide the flexibility needed to fit a wide range of needs. For example, thermally efficient dampers can be used in conjunction with dedicated outdoor air systems (DOAS) and air handling units (AHU) paired with airflow measuring devices to ensure a precise amount of air volume is being introduced into the system or space.

Measuring thermal performance

Precise operation and thermally efficient design is critical to damper performance, as air leakage is a critical component of the thermal efficiency equation, combined with heat conduction. In winter, the damper blades need to form a very tight seal to keep the space warm and prevent cold air from entering an opening that may be used to admit outside air for ventilation during the summer. Better leakage prevention is one reason why some non-thermal dampers can outperform insulated thermal dampers that are labeled as thermally efficient.

R-value Method

There are several methods used to measure damper performance. In the past, an engineer might specify a damper based on an R-value, the same metric used to measure heat transfer through a building material such as insulation.

R-value is the measure of resistance to conductive heat flow through a material, which varies by the material’s properties, such as thickness. The higher the R-value, the better the material's ability to resist heat transfer.

R-value ratings are determined by the American Society for Testing and Materials, (ASTM C 976-90) Standard Test Method for Thermal Performance of Building Assemblies by Means of a Calibrated Hot Box.

There are two major parts of the damper – the blades and the frame – where heat transfer through the material is of concern and where R-value is relevant. However, due to different materials and thicknesses used in damper construction, R-value is only one aspect to consider in determining overall thermal efficiency of the damper. In fact, damper manufacturers may use R-values differently depending on the performance of a single component. For example, an R-value may be promoted for the insulation used in a damper blade but does not account for the thermal efficiency of the other materials in the blade or the frame.

AMCA methods

Because R-value tells only part of the story, other measurements have been developed by the Air Movement and Control Association (AMCA) to determine overall damper performance.

Two relevant AMCA standards are:

1. AMCA Standard 511, Certified Ratings Program Product Rating Manual for Air Control Devices details procedures for participation in the AMCA Certified Ratings Program (CRP). Manufacturers having their products tested in an AMCA-accredited laboratory, with the test results verified by the AMCA staff and then having obtained the proper license from AMCA, can offer products bearing AMCA’s Certified Ratings Seal for Air Leakage.

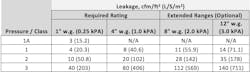

AMCA 511 also introduces damper air leakage classes. The maximum allowable leakage rates defined by AMCA are shown in this chart.

One item to note is that air leakage, not light leakage, is the critical factor. It’s a common misperception that light leakage indicates damper blades are not tightly sealed. Damper seals can eliminate a path for airflow, but light may still find a transmission route.

2. AMCA Standard 500-D-12: Laboratory Methods of Testing Dampers for Rating establishes uniform laboratory test methods for dampers including air leakage, pressure drop, dynamic closure, and operational torque. It also provides methods to calculate a damper’s thermal efficiency ratio (E), which is the energy lost by conduction of heat through the dampers blades and frame. Thermal efficiency testing compares a complete AMCA standard reference damper assembly – including blades and jamb seals – with the damper being evaluated, or specified. A damper with the same Thermal Efficiency Ratio (E) as the reference damper would have an E of 0%. A damper that is three times as efficient as the reference damper would have an E of 300%.

Damper features that improve thermal efficiency

To maximize thermal efficiency, manufacturers enhance several key damper components. In specifying a thermally efficient damper, it’s imperative to evaluate the design of the airfoil blades, the blade seals and the jamb seals to ensure a high overall damper efficiency rating.

Blade insulation:

In thermally insulated damper blades, the interior of an airfoil-shaped blade should be filled with a high-density polyurethane foam. The foam is injected into the blade where it fills the cavity without gaps and extends down the edge. Polyurethane foam has an inherently high R-value and enables a very low heat transfer that contributes to a high Thermal Efficiency Ratio (E).

Blade seals:

A bulb blade seal is particularly effectively in helping block heat transfer through the blade seal. That’s because a bulb seal creates an air pocket, which is a thermal insulator in itself. As a result, a double-insulation effect is created from both the rubber blade material and the air block.

Blade jamb seals:

Jamb seals should be made from silicone or similar durable and non-conductive material. Ruskin, for example, uses a proprietary material (Ruskiprene™) that protects against both condensation and heat transfer better than stainless steel. Stainless steel side seals are not ideal in cold weather environments because steel readily conducts heat. Moreover, metallic surfaces allow condensate to form and travel. In contrast, Ruskiprene seals employ a fingerling pattern along the side of the blade to ensure tight compression. Ruskiprene and silicone also have the advantage in humid applications by preventing condensation from sliding through.

Thermally broken blade:

A thermally efficient damper blade requires isolation between the warm and cold sides of a damper even if the blade is insulated. Look for a thermal break strategically placed between twin blade edge seals. Twin seals create a neutral zone to ensure there is no thermal path. These features eliminate thermal transfer and reduce condensation potential.

Thermally broken frame:

Just as with blades, a thermally broken frame isolates the high delta T sections across the damper to improve thermal performance. This is a feature to look for that further minimizes the transfer of cold or heat.

Additional considerations for durability and better thermal efficiency over time

Although the design features above are crucial to improving overall thermal efficiency, it’s important to consider some additional factors that improve damper durability and thereby ensure thermal efficiency over the life of the damper.

To withstand more extreme environments, aluminum damper construction transfers less heat and provides superior corrosion resistance vs. steel to protect against pitting that can compromise sealing and service life. This is especially important in high-condensation environments, like pools, or high-corrosion environments and critical environments, such as spark-proof laboratories.

For application flexibility, components can be completely customized, including:

- Blade materials, jamb seals for corrosion resistance in a given temperature range;

- Additional anodized finish for extra protection in corrosive or wet environments;

- Stainless steel axles, bearings and linkages in place of plated steel linkages.

As a result of enhanced design, advanced materials and integrated engineering, thermally efficient dampers can meet a wide range of application requirements and ambient conditions. Depending on the application, thermally efficient dampers can reduce energy costs significantly compared to standard dampers. Extrapolate that over a hundred dampers in a single building, and building owners can realize substantial savings per year vs. the use of less efficient dampers.

The potential for increased energy savings makes it worthwhile to specify thermally efficient dampers. However, when evaluating choices for a thermally efficient damper, be sure to consider more than just the R-value. It’s important to look at the overall damper efficiency as well as the durability factors that ensure efficiency over a longer life span.