Practical Ways to Reduce Legionella Contamination

By PETE DeMARCO

IAPMO Group

New York, NY

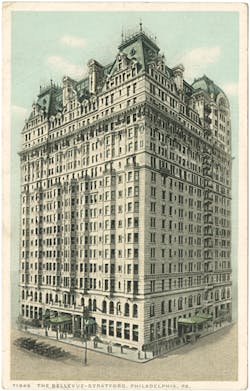

Legionella is big news again. It certainly was a big story in 1976 when a major outbreak of a mysterious illness occurred during an American Legion convention at a Philadelphia hotel. The resulting investigation led by the Centers for Disease Control and Prevention (CDC) produced television drama and cover stories in both Time and Newsweek magazines. Ultimately, public health officials identified the culprit bacterium that caused the disease and named it “Legionella.”

Today, new outbreaks of Legionnaires’ disease and Legionella contamination continue to be reported in the United States and around the globe. For example, in late January 2018, preliminary test results showed the “possible presence” of Legionella bacteria in a “dead leg” of the water system at the Illinois Capitol Complex in Springfield, IL, according to the State Journal-Register. Instances like this prove that more research is needed on identifying the best strategies for preventing future outbreaks of Legionnaires’ disease from the water in our premise plumbing systems.

Plumbing Manufacturers International (PMI) recently released new content, “Just the Facts: Legionella and Water Supply Systems,” discussing the threats posed by this waterborne pathogen and the need to continue advocating for water system safety. Compiled using many scientific, industry and other resources, the document also examines industry standards developed to control the bacteria and key ways to prevent Legionella growth. This report is an excellent resource for anyone looking to obtain a working knowledge on the current status of the Legionella issue and the challenges faced by water utilities and the plumbing industry to keep our water systems safe.

Understanding key elements for growth

• First, it is important to understand the key elements that can provide the ideal environment for Legionella growth in a water system. They include the following, from PMI’s report;

• The longer water sits in a system or piping in a system, the greater likelihood the water disinfectant will dissipate over time, leading to pathogen growth;

• When biofilm, a sticky substance created by bacteria, forms on the inside wall of water supply piping, it protects Legionella from heat and disinfectant;

• Legionella growth is enabled by lukewarm water temperatures, usually in the range of 77 degrees Fahrenheit to 108 degrees Fahrenheit;

• A “dead leg” is a portion of a plumbing system that is stagnant or has rare flow of water in the pipes (an emergency eye-wash station, for example);

• Today’s lower flow rates, consistent with modern plumbing fixtures and appliances, have led to longer transit times in water utility distribution systems. As a result, water is arriving at buildings, especially at the outer fringes of the system, with little or no residual disinfectant. This contributes to the potential for pathogen growth in the premise plumbing system;

• With increased use of rainwater catchment and graywater systems in buildings, cross connections between potable and improperly maintained non-potable water sources can introduce Legionella into the potable water supply system;

• Once it grows, Legionella can potentially be spread by any component in the plumbing system that generates an aerosol or a fine mist of water. Large complex plumbing systems, like those in hospitals, retirement communities and cruise ships, are most often associated with outbreaks of Legionnaires’ disease and are especially problematic for at-risk people with compromised immune systems.

Developing a strong safety plan

The most comprehensive way to reduce the risk of Legionnaires’ disease outbreaks is to design, implement and regularly update an overall building water safety plan. The plan should be based on an engineering audit of a building’s water system, consider any potential hazardous conditions and potential areas of pathogen growth for that system, and include industry best practices to prevent Legionella contamination.

In 2015, ASHRAE published the international standard, “Legionellosis: Risk Management for Building Water Systems,” ASHRAE 188. This American national standard establishes minimum risk management requirements to control the transmission of Legionellosis in water supply systems.

Design also plays a major role in mitigating the growth of Legionella in plumbing systems. Section 8 of ASHRAE 188 details the need to properly document a building’s plumbing systems design, identify areas of potential pathogen amplification, and eliminate features that can contribute to potential outbreaks, such as dead legs. Section 8 also details system disinfection best practices, the need for commissioning and periodic re-commissioning of building water systems, and more.

The new sizing method, along with an easy-to-use Water Demand Calculator, appear in the appendices of the 2018 Uniform Plumbing Code and the 2017 WE-Stand water-efficiency standard.

The codification of ASHRAE 188, along with its complementary Guideline 12, will go a long way toward addressing the potential for future outbreaks. Enforcement will require a coordinated effort from both health and building code officials. New York City has already taken the lead by adopting portions of the standard for controlling Legionella in cooling towers – in response to a major outbreak of Legionnaires’ disease in 2015.

New pipe sizing methods for premise plumbing systems also will play a part in mitigating Legionella growth. Recent research conducted by the American Society of Plumbing Engineers (ASPE), IAPMO and the Water Quality Research Foundation (WQ-RF) has led to development of the first statistically based update to the Hunter’s Curve pipe-sizing method since the 1940s. The new method considers the greatly reduced flow rates and consumption values of plumbing products and appliances, allowing for the use of smaller diameter pipes in plumbing systems. This results in a shorter water dwell time in the plumbing system and higher flow rates that work to better scour interior pipe walls and inhibit biofilm growth. This method also provides for shorter hot water delivery times and greater water and energy efficiencies. The new sizing method, along with an easy-to-use Water Demand Calculator, appear in the appendices of the 2018 Uniform Plumbing Code and the 2017 WE-Stand water-efficiency standard.

Currently, the scope of the pipe-sizing research only applies to residential buildings, but researchers are confident it also can be effectively and safely applied for non-residential buildings. What’s lacking are explicit data on how water is used in non-residential buildings. IAPMO is working with PMI and other industry partners to advocate for the National Institute of Science and Technology, where Hunter’s Curve was originally developed, to once again engage in this issue by working with industry stakeholders to research how water use with the new pipe-sizing formulas can be applied and codified for non-residential buildings.

We have indeed come a long way since 1976. However, much research remains to be conducted and building owners and facility managers will need to be educated on the new and emerging strategies that will help reduce the risks of future Legionnaires’ disease outbreaks.

To view PMI’s “Just the Facts: Legionella and Water Supply Systems,” visit the PMI website at www.safeplumbing.org/health-safety/legionella-and-water-supply-systems.