Armstrong’s Sustainability Journey

By OFER BEN-DOV, MA, MES, Armstrong Fluid Technology, Toronto, Canada

Earlier this year at the Global Energy Summit in Toronto, Armstrong Fluid Technology announced the ‘2 in 22’ initiative designed to help building owners and managers reduce CO2 emissions by 2 million tons by the year 2022. The company invited other manufacturers and industry leaders to join them in this bold initiative to reduce customers’ CO2 emissions and achieve new levels of energy savings.

However, Armstrong’s sustainability efforts began many years before the announcement at the Global Energy Summit. The company has a history of promoting energy efficiency in HVAC solutions, and was one of the early adopters of variable speed technology to HVAC pumps.

In 2004, the company launched the first version of an intelligent variable speed drive solution that integrated the drive and motor, in what would later be known as Design Envelope technology. It was in 2008, at an event to officially launch Design Envelope technology that Armstrong first began to actively promote sustainability as an important driver for energy savings and efficient solutions.

Measuring Progress

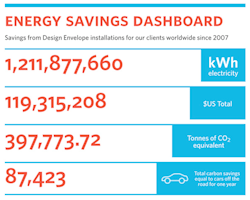

As part of this strategic sustainability journey, the company launched a web-based Sustainability Calculator shortly thereafter, intended to present the energy savings and carbon footprint reduction of their solutions as they were installed and operating at customers’ locations. Within five years, Armstrong reported that customers were already reducing CO2 emissions by tens of thousands of tons and savings millions of dollars in kWh reduction. These efforts resulted in carbon savings equivalent to taking more than 25,000 cars off the road for one year.

In early 2013, the company embarked on a new sustainability journey which began with the formulation of a charter titled the ‘Planet Proposition’. The charter was based on the realization that fluid-flow management is an important component of urban life, and that climate change and other sustainability drivers will require a change in how buildings manage their energy consumption.

Armstrong’s Leadership Board agreed to the charter and champions have been empowered at each of their locations. The focus has been for the selected champions to communicate the aims and benefits of the ‘Planet Proposition’ program and to seek active involvement and commitment at all levels of the organization. 'Planet Proposition' teams were appointed in all locations to manage the ongoing efforts. In late 2017, a full-time Global Sustainability Leader was hired to further develop the program.

Armstrong defines a sustainable business as an enterprise that measures its success based not only on economic gain but also on its achievements in preserving the environment and bettering humanity, particularly among employees and local communities.

Internally, Armstrong committed to reduce its CO2 Scope 1 and Scope 2 emissions by 20% in 2022 over 2014 levels. However, the new sustainability agenda was not limited to improving just the operational aspects. A key component was to reduce the Scope 2 emissions of customers through the development of highly efficient, smart, and connected solutions that would deliver a new level of energy savings and sustained system optimization.

Focusing on Usage

In line with the results of independent research efforts, Armstrong found that the carbon emissions from the use-phase of its products represents well over 90% of the overall product lifecycle emissions. This finding has helped focus R&D efforts on further reductions to energy consumption of the products and expansion of their system integration capabilities to drive energy savings on a system level.

In 2017, Armstrong initiated a sustainable procurement program with the aim to improve its upstream sustainability performance, and this year, Armstrong started to calculate its products’ carbon footprint. All have the aim of improving the product’s environmental footprint.

On the operational level, Armstrong was able to reduce its Diesel consumption by 35% between 2014 and 2017, and overall absolute Scope 1 emissions by 22%. One initiative involved the design decision to eliminate all plastic, wood and metal from the packaging of the newest Design Envelope pumps. The development team was able to design a cardboard-only packaging solution, with a much smaller environmental footprint compared to previous packaging practices.

As mentioned above, another major sustainability milestone was the launch of the ‘2 in 22’ commitment to reduce CO2 emissions at the customer level by 2 million tons by 2022. Armstrong is confident in the ability of its technology and solutions to generate these reductions and has restructured internal compensation systems to incorporate the ‘2 in 22’ commitment.

Moving forward, the organization has adjusted its goals and activities to focus on the use-phase of products and solutions, rather than the production phase. This is based on an understanding that 90% of the GHG emissions from the entire lifespan of their solutions are a result of usage post installation.

More Careful Management

Armstrong has also launched an ambitious program named Active Performance Management that is a combination of solutions and services aimed at helping customers reduce their environmental impact through carefully considered solution choices and careful management of mechanical systems and their buildings. This program includes intelligent pumps that operate more efficiently using feedforward control algorithms to modulate speed. It also includes performance and efficiency tracking using real-time data instead of estimations.

Armstrong is also offering customers a consultative approach to the purchase, installation and operation of HVAC systems, offering services related to energy efficiency. Savings guarantees, financing programs and innovative payment plans are all constructed and offered as a way to encourage customers to make careful decisions regarding components and systems for their buildings.

Lastly, Armstrong has committed to preparing and publishing an annual report on its sustainability efforts. Progress to date has been encouraging and suggests that while the effort involved in making changes is substantial, the opportunities to minimize environmental impact are even greater than originally envisioned.

The commitment is obviously in place, as well as the opportunity, so the path forward seems clear. As was originally explained when the ‘2 in 22’ program was unveiled, Armstrong has invited and challenged other industry participants and stakeholders to join them in making similar commitments to sustainability.

###################

A practical engineer and environmental consultant, the author is Armstrong Fluid Technology’s Global Sustainability Leader, having joined the firm last December. An alumnus of both Greenpeace and the Israeli Air Force, Ben-Dov is a passionate advocate for renewable energy and clean technologies.