Ultraviolet (UV-C) Lamps: Fact or Fiction

Despite recognition for significantly improving airflow and heat-transfer efficiency and lowering costs associated with HVACR systems, ultraviolet (UV) light in the 253.7-nm germicidal C-band wavelength (UV-C) is widely misunderstood and, thus, underutilized. This article attempts to set the record straight and improve understanding of how UV-C lamps operate.

UV-C is new technology: Fiction

Though it may seem futuristic—something about that crisp blue light screams science fiction—UV-C technology got its start in the 1940s. One veteran facility manager who recently installed UV-C remarked, “I remember the lights being mounted over my doctor’s door to kill germs.” Since the mid-1990s, UV-C has been used to improve airflow and heat-exchange efficiency.

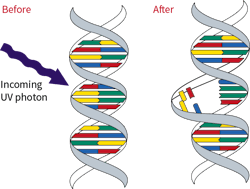

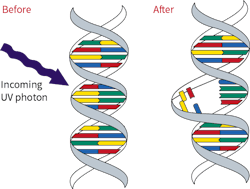

UV-C kills virtually all organisms: Fact

With a kill ratio of 90 percent or higher, depending on the intensity, length of exposure, lamp placement, and lamp life cycle, UV-C inactivates virtually all microorganisms living on HVACR surfaces, ASHRAE says. A 2013 Centers for Disease Control and Prevention-funded study conducted in two hospitals found UV-C reduced the total number of colony-forming units of any pathogen in a room by 91 percent.1

Science has yet to find a microorganism, including superbugs and antibiotic-resistant microbes linked to health-care-associated infections, totally immune to the destructive effects of UV-C.

UV-C’s primary application in HVACR systems is on-the-fly kill: Fiction

UV-C does more than disinfect air. It is a widely accepted means of surface irradiation in HVACR systems, used to eliminate microbial buildup on drain pans, cooling coils, and other components.

UV-C can restore HVACR-system performance: Fact

As mold, biofilm, and other organic compounds accumulate on cooling coils and other surfaces, a HVACR system becomes less efficient, forcing operators to make energy-intensive adjustments, such as lower chilled-water temperature and/or increase fan speed.

In a new HVACR system, continuous (24/7/365) bombardment of UV-C energy will prevent such buildup from occurring. In a retrofit application, it will degrade organic matter that has accumulated and prevent it from reforming (so long as the lamps are replaced regularly—more on that next), returning air handlers to as-built operating conditions in as little as 90 days.

UV-C energy reflects exceptionally well and penetrates deep into coils to eliminate buildup that cannot be reached by mechanical (pressure washing) or chemical treatment.

Installed in older systems, UV-C reduces energy use by up to 25 percent.

UV-C lasts forever: Fiction

With UV-C lamps, it is easy to “install and forget.” Alas, nothing lasts forever. UV-C-lamp manufacturers rate their products’ “useful life” at 9,000 hours, or slightly longer than a year of continuous operation. At that point, a lamp’s output can fall to 85 percent. To maintain performance and protect against equipment failure, facility managers are wise to establish an annual lamp-replacement schedule.

UV-C energy can cause permanent damage to humans: Fiction

Anything can be safe or dangerous, depending on how it is handled. The same applies to UV-C. Taking the common-sense steps of placing warning labels on access points to UV lamps, installing electrical disconnect devices (e.g., toggle switches and safety interlock switches), and educating service personnel and building occupants about UV-C exposure always is recommended.

Accidental exposure to UV-C energy can cause erythema, a reddening of the skin, which, depending on the length of the exposure, goes away within a short period of time. Exposure to the eyes can cause temporary inflammation of the cornea or conjunctiva, which typically resolves within 24 to 48 hours, again, depending on exposure time.

Viewport glass does not protect against UV: Fiction

UV-C light is viewed most safely through an air handler’s viewport. Not being “pure” (e.g., quartz), the glass typically used for viewports blocks the UV-C bandwidth. Viewport windows can be checked for safety with the use of a radiometer tuned to the 253.7-nm germicidal C-band wavelength. Some UV-C manufacturers offer in-field testing, which can confirm viewport glass is blocking UV-C energy, after which a “UV-C Safe Glass” sticker can be applied to the window.

UV-C is expensive: Fiction

UV-C has an average installed cost of 15 cents per cubic foot per minute. For systems with high-output lamps, many users report costs that are even less.

Using a 10,000-cfm system as an example, the installed cost of the UV-C fixtures would be $1,500. With 24/7/365 operation at a rate of 10 cents per kilowatt-hour, the annual operating cost would be $188. That is less than 1 percent of the average power savings gained through a more efficient (better heat transfer and lower pressure drop) air-conditioning system.

Field reports indicate the initial cost of a UV-C system is about equal to the cost of a properly performed coil-cleaning procedure. It is less when system shutdowns, off-hours work and associated overtime, and/or contractor labor costs are considered.

UV-C energy is blue: Fiction

The blue color visible in a UV-C lamp does not come from the UV-C wavelength, which has no color. It comes from argon gas in the lamp. When an electrical current is applied to a lamp, it “excites” the mercury to generate a photon with a wavelength of 253.7 nm, which is invisible.

UV-C has residential and light-commercial uses: Fact

UV-C is not just for hospitals, office buildings, institutions, and data centers. It also can be put to use in residential HVAC systems to provide cleaner air, improve airflow, and raise heat-exchange efficiency. Some UV-C lamps install easily on the exterior of HVACR plenums and are ideal for residential and most light-commercial applications.

Reference

- Anderson, D.J., et al. (2013, May). Decontamination of targeted pathogens from patient rooms using an automated ultraviolet-c-emitting device. Infection Control and Hospital Epidemiology, 34, 466–471.

The president and co-founder of UV Resources, Daniel Jones is a corresponding member of ASHRAE Technical Committee 2.9, Ultraviolet Air and Surface Treatment, and ASHRAE Standard Project Committee SPC-185.2, Method of Testing Ultraviolet Lamps for Use in HVAC&R Units or Air Ducts to Inactivate Microorganisms on Irradiated Surfaces. He can be reached at [email protected].

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].