EPA's Top 10 Building Water Management Techniques

From the U.S. Environmental Protection Agency:

Water management plans help individual facilities set long- and short-term water conservation goals. EPA currently has 27 signed water management plans that outline the best management practice for 30 different EPA facilities across the U.S. Here are the Top 10 water best management practices that the agency has implemented to reduce water use at its facilities.

1. Meter/Measure/Manage

Metering and measuring facility water use help to analyze saving opportunities. This also assures the equipment is run correctly and maintained properly to help prevent water waste from leaks or malfunctioning mechanical equipment.

A cooling tower at EPA’s Environmental Science Center in Fort Meade, Maryland.

2. Optimize Cooling Towers

Cooling towers provide air conditioning for laboratories and are large consumers of water. Cooling tower operations can be optimized by carefully controlling the ratio of water discharged (blowdown) to water evaporated. The ratio of evaporation to blowdown is called the cycle of concentration. For maximum water efficiency, cooling towers should be operated at six or more cycles of concentration. Metering water put into and discharged from the cooling tower ensures the cooling tower is operating properly and can help identify leaks or other malfunctions.

- The Environmental Science Center in Fort Meade, MD, saved 530,000 gallons of water and approximately $1,800 by reducing its cooling tower blowdown.

3. Replace Restroom Fixtures

The U.S. Department of Energy established federal water-efficiency standards in the 1990s. Prior to that, most EPA facilities had inefficient sanitary fixtures. For example, toilets used 3.5 gallons per flush (gpf). Nearly all EPA laboratories have since installed water-efficient fixtures, many of which have earned EPA’s WaterSense label for efficiency and performance. These include:

- New toilets with flow rates of 1.28 or 1.6 gpf;

- WaterSense labeled urinals flushing at 0.5 gpf or less;

- WaterSense labeled showerheads flowing at 2.0 gallons per minute (gpm) or less.

Faucet aerators flowing at 0.5 gpm, well below the 2.2 gpm federal standard, have also been installed in most laboratories.

4. Eliminate Single-Pass Cooling

Single-pass cooling circulates a continuous flow of water just once through the system for cooling purposes before it goes down the drain. EPA strives to eliminate single-pass cooling in its laboratories. Instead, facilities have air-cooled or recirculating chilled water systems.

- The National Vehicle and Fuel Emissions Laboratory in Ann Arbor, MI, replaced its single-pass cooling system with a recirculated chilled water loop. This cut water use 80%, saving the laboratory 24.8 million gallons of water and $235,000 annually.

5. Use Water-Smart Landscaping and Irrigation

Planting native and drought-tolerant plant species minimizes the need for supplemental irrigation. Landscape water use can also be reduced 10 to 20% by having an irrigation water audit. EPA selects audit professionals certified through a WaterSense labeled program. WaterSense labeled weather-based irrigation controllers or soil moisture sensors are used to water only when plants need it.

6. Control Steam Sterilizer Water

Steam sterilizers use cooling water to temper steam condensate discharge from the sterilizer to the laboratory drain. Many older sterilizers discharge a continuous flow of tempering water to the drain, even when it is not needed. EPA has retrofitted sterilizers with a tempering water control kit or replaced old steam sterilizers with models that only apply tempering water when needed.

- The Western Ecology Division Laboratory in Corvallis, OR, installed tempering water control valves on its sterilizers. This has saved approximately 1.5 million gallons of water and $6,000 to $9,000 annually.

7. Reuse Laboratory Culture Water

Several EPA laboratories require water for aquatic culture research. In some cases, culture water is pumped into laboratory specimen tanks from local bodies of water, such as lakes or bays. It is then discharged into the sewer or treated and returned to the body of water.

- The Mid-Continent Ecology Division Laboratory in Duluth, MN, uses approximately 35 to 40 gallons per minute of Lake Superior water for its laboratory research.

EPA’s Mid-Continent Ecology Division Laboratory pumps water from Lake Superior in Duluth.

8. Control Reverse Osmosis System Operation

Up to 10% of a laboratory’s water consumption can be related to the multi-step process of generating deionized (DI) purified water through reverse osmosis (RO). Water savings can be achieved by carefully regulating purified water generation rates to meet laboratory demand and making sure that systems are sized accordingly.

- EPA's Environmental Science Center in Fort Meade, MD, saves approximately 1.5 million gallons of water and more than $5,000 in annual water costs by reducing DI/RO system operation from 24 hours per day to 12 hours per day.

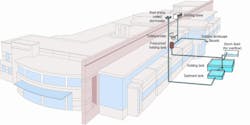

9. Recover Rainwater

Recovery systems capture rainwater from the roof and redirect it to a storage tank. This water is used for flushing toilets, supplying cooling towers and irrigating the landscape.

- The Region 7 Science and Technology Center in Kansas City, KS, has incorporated a state-of-the-art rooftop rainwater recovery system that has the potential to save the laboratory more than 300,000 gallons of water per year.

View a larger version of this image. A rooftop rainwater recovery system in Kansas City.

10. Recover Air Handler Condensate

Air conditioning units produce condensate water from the cooling coils. Many EPA laboratories are capturing this water for use as cooling tower make-up water.

- The Region 4 Science and Ecosystem Support Division Laboratory in Athens, GA, captures 400,000 gallons of condensate from three rooftop air handlers and routes it to the facility cooling tower.

For more information on water-saving best practices, please visit https://www.epa.gov/watersense/commercial-buildings.