Practical Applications of Smoke-Control Systems

Design criteria for smoke-control systems have changed over the years. Instead of ventilating an affected area, smoke-control systems now must prevent the spread of smoke to non-affected areas and/or provide a tenable environment in the area of incident. How effective are current smoke-control systems? Can building-code requirements for smoke-control systems be met reasonably? How can applications not described in building codes be addressed?

Smoke-control-system requirements have been in place for years, and smoke-control-system design has had to adapt to building-code-requirement changes. This article will address some practical design applications of these systems as well as how building-code requirements can be applied. The article also will address ways to adapt a design to meet building-code intent.

History of Smoke-Control Requirements

Smoke-control systems have been utilized in high-rise buildings since the mid-1970s. In early building codes, mechanical systems were required to provide a specific exhaust rate to ventilate a space; building codes later required specific air-change rates, typically six air changes per hour (ACH).

The 1994 edition of the Uniform Building Code (UBC) required smoke-control systems to be designed using a performance-based approach according to one of four basic design methods: pressurization, passive, airflow, and exhaust. These methods were tied to National Fire Protection Association (NFPA) standards for smoke-control systems. Design criteria for the pressurization, passive, and airflow methods included maintaining smoke in the zone of origin to prevent its spread throughout a building; the exhaust method's criteria included maintaining the smoke layer above the highest walking surface in an effort to maintain a tenable environment.

Since the adoption of the 1994 UBC, other model codes have incorporated these design requirements. The International Building Code (IBC) and International Fire Code (IFC) include language similar to that in the 1994 UBC. Refinements have been made to the UBC to stay current with NFPA standards, but the criteria have remained much the same as when the four design methods were introduced in 1994.

The IBC requires smoke-control systems for atria, three-story covered malls, and underground buildings, but offers them as an option in lieu of smoke venting. Although the IBC does not mandate smoke-control systems for high-rise buildings, certain jurisdictions have amended the code to require them, similar to what was required by previous editions of the UBC. Since performance-based design criteria were introduced, many buildings have been outfitted with smoke-control systems using this approach.

Pressurization Method

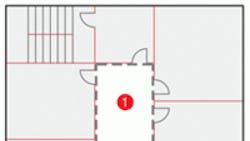

Smoke-control systems using the pressurization method maintain a pressure difference between the zone in alarm and adjacent zones. To maintain a minimum pressure difference of 0.05 in. w.c., a mechanical system typically is configured with 100-percent exhaust, with no supply air introduced into the zone. Zone barriers are required to be intact and closed; doors and dampers must close and seal off the zone. This design method can be effective in preventing the spread of smoke to other areas of a building (Figure 1).

The pressurization method is most widely used for areas that have the ability to be sealed, such as individual floors and back-of-house spaces. However, barriers need to be maintained to ensure the zone envelope is intact. Otherwise, the system cannot maintain the required pressure difference. Maintaining smoke-zone barriers over long periods of time can be difficult, in part because alterations to spaces adjacent to the barriers can cause leaks. Alterations also can result in work on smoke-barrier walls by personnel unfamiliar with the walls' requirements. Without proper documentation of the location of smoke-barrier walls, alterations can render these systems useless. A smoke-control system designed with the pressurization method can be effective if adjusted properly and maintained.

Sizing exhaust fans for pressurization systems can be challenging. The exhaust required to achieve a desired pressure difference depends on construction leakage. Building codes provide leakage rates that can be used in choosing an exhaust fan. However, a design may need to accommodate construction that is tighter than building codes allow, which could result in overpressurization. Selecting fans to operate effectively under various ranges of operation can help minimize field changes or equipment replacement during initial commissioning.

To overcome construction issues and account for future renovations, variable exhaust from the space can be utilized to build in some form of airflow adjustment. Many designers use variable-frequency drives (VFDs) to control fan speed for HVAC design. Smoke-control systems can be balanced by adjusting their VFDs. If pressures need to be adjusted during initial setup and recommissioning, VFD settings can be used to achieve the proper exhaust, eliminating the need to change motors or other equipment to adjust pressure differences. Using VFDs does pose some operational restrictions because they are part of the smoke-control systems and should not be adjusted by people unfamiliar with the systems' requirements.

A practical application of HVAC technology and the design of smoke-control systems, the pressurization design method employs equipment to condition a space and simultaneously serve as a smoke-control system. Once a system is adjusted properly, it can continue to provide the protection intended by building codes. However, knowledge of system-design requirements, including the location of smoke-barrier walls, is needed to maintain the effectiveness of a smoke-control system.

Modified Airflow/Exhaust Method for Parking Garages

Parking garages requiring smoke control present unique challenges. It generally has been accepted that a parking garage meeting building-code requirements for an “open garage” does not need mechanical smoke control because the number of openings along the building perimeter do not allow smoke to collect within the garage. Mechanically ventilated garages pose design challenges when smoke-control systems are required, but design methods in the IBC do not readily lend themselves to practical solutions. Designers often use hybrid designs to provide effective smoke control in parking garages.

Enclosed garages typically are required to have mechanical ventilation for vehicle-exhaust (carbon-monoxide [CO]) removal. These systems can be effectively used for smoke control if certain design parameters are established. Until recently, the exhaust method was not possible in spaces in which a 10-ft smoke layer needed to be maintained because of the limited clearance height of a typical garage. The 2006 IBC lowered the smoke-layer height to 6 ft, making this design method slightly more practical, but the limited smoke-layer depth leaves exhaust inlets susceptible to plugholing. Also, CO exhaust inlets are not located solely at the ceiling, meaning an inlet could be located below the smoke layer if the exhaust method is used.

The pressurization method also can be used to fulfill building-code performance requirements for a garage. Because the pressurization method requires a sealed area, the garage would require roll-down doors for any openings, such as drive lanes. However, this can present a scenario in which doors close off traffic lanes, restricting emergency-response vehicles. While the smoke-control system will perform as intended by code, it is not an effective solution because it can restrict emergency-response access.

A hybrid design combining the exhaust and airflow methods also can be used for smoke control in enclosed parking garages. This concept provides an exhaust rate for the garage while maintaining velocities of less than 200 fpm across an opening, as required by the airflow method. The hybrid design recognizes that garages cannot effectively have a smoke-layer height of even 6 ft above the floor because of limited clearances and the amount of ductwork routing required to extract smoke at the ceiling level. While this approach is not one of the prescribed building-code design methods, it can be effective in exhausting smoke from an enclosed garage using equipment already in place. Additionally, the use of VFDs can allow the adjustment of fans in the field to achieve the desired airflow.

Exhaust Method for Large Spaces

Using the exhaust method for very large areas, such as an assembly space or casino, is a practical choice for smoke control. Relatively high ceilings and common return-air plenums make exhausting large quantities of air straightforward. Makeup air can come from adjoining areas. Draft curtains can separate a large space from adjoining retail promenades, meeting rooms, restaurants, etc.

However, various issues need to be addressed when the exhaust method is being considered for a large space. Smoke-zone areas may become too large, requiring multiple smoke-exhaust fans. Exhaust fans should be within 200 ft of a fire for smoke to be extracted. For large open areas, multiple fans are necessary to limit the travel of smoke from the fire to the exhaust inlet. When multiple fans are used, the exhaust quantity is increased, which impacts the ability to provide adequate makeup air. A single extraction point can provide 50,000 cfm of exhaust easily when makeup air is equal to the exhaust rate. However, if a large zone requires four extraction points, the increased total exhaust and makeup-air rate of 200,000 cfm is more difficult to accommodate.

To manage large areas using the exhaust method, smaller smoke zones are needed. Utilizing smaller zones reduces the amount of exhaust and helps manage makeup air. However, creating smaller zones within a larger area requires additional smoke dampers, as well as draft curtains below ceilings. These items will increase construction costs and could have negative effects on the aesthetics of a space. Draft curtains are difficult to create in high-ceiling areas.

A more practical solution is to modify the exhaust approach, utilizing the entire area as a single smoke zone and creating smaller “activation zones” within the common smoke zone (Figure 2). This works well when a common return-air plenum is used. An overall smoke zone surrounded by appropriate boundary walls contains multiple activation zones that are served individually by smoke-exhaust fans chosen based on the design-fire size/smoke-layer height and corresponding smoke-exhaust rate in the activation zone. When a smoke-control system is activated, all of the smoke-exhaust fans within the activation zone are energized. This provides the required exhaust rate for the activation zone and obtains makeup air from adjoining zones, keeping velocities across the openings for the overall smoke zone within building-code-required limits.

Smoke migration to other activation zones is not considered an issue because the smoke is within the same smoke zone. However, because exhaust inlets are located within the activation zone, smoke has a tendency to be drawn toward the exhaust fans in operation. This limits the potential for smoke damage remote from the area of incidence while keeping initial construction expenses down. Draft curtains are not required between activation zones because they are treated as subzones to the overall smoke zone. This can be an effective way to provide required smoke control while minimizing the impact on the construction costs and aesthetics of a space.

Exhaust Method for Tall Atria

Since the 1980s, atria have been required to have smoke-control systems. Design criteria in early building codes were based on the air-change method, in which the volume of the space dictated the required exhaust-air quality. (A larger atria may require only four ACH, while a smaller atria may require six.) More-recent building codes have recommended the exhaust design method, which maintains the smoke layer at a certain height.

NFPA exhaust-method standards include formulas that depend on two basic variables: the height of the smoke layer above the fire and the fire size. The height of the smoke layer is dictated by building design, and the fire size is dictated by fuel loads and suppression-system design. While the density of the air at the smoke layer has some impact, smoke-layer height and fire size are more important issues for the equations.

Building design dictates smoke-layer height because a smoke layer must be a minimum of 6 ft above the highest walking surface. Within tall atria, this can be very high. Unless the space is redesigned, this variable cannot be changed. Fire size can be adapted to the space by limiting fuel or controlling the fire in its early inception stage with quick-response sprinklers or detection systems operating deluge systems.

The equations found in NFPA standards can produce large exhaust requirements for tall atria. Building codes also require an equal amount of makeup air produced by mechanical or natural means or a combination of the two. Building codes limit makeup air to no more than 200 fpm of airflow toward the fire. While large quantities of exhaust air can be difficult to manage, tackling large quantities of makeup air is even more difficult. Buildings often have insufficient space to allow vents and louvers to introduce makeup air under the prescribed maximum velocity.

Makeup air must be introduced below the smoke layer. In tall spaces, multiple levels may be available to introduce makeup air. In smaller areas, wall space may be insufficient. In these cases, operable panels or doors in an exterior wall can be used to introduce makeup air by natural means. Makeup air also can be introduced by adjacent zones when multiple zones are present (Figure 3).

Makeup air can be difficult to provide in atria because of the physical constraints of the building design. Tall atria with walking surfaces located near the top can require exhaust rates exceeding 300,000 to 400,000 cfm. When makeup air is equal to the exhaust rate and limited to no more than 200 fpm, smoke-control systems can require up to 1,500 to 2,000 sq ft of free vent area. If grilles are used, the free area often is much smaller than the actual size of the grille. If panels or doors are used, a large quantity may be needed to meet the free-area requirements.

There are ways to limit the impact of smoke control in tall atria. The best method is to reduce the height of the highest walking surface in the atrium or provide a way to separate the walking surface from the atrium under a fire condition, such as with fire shutters. If the building design cannot accommodate either option, the fire size needs to be limited with sprinkler control and smaller fuel loads. Another approach is to use a computational flow analysis to determine actual exhaust quantities based on performance objectives. These types of analyses can help reduce NFPA-standard exhaust rates for exhaust-method systems or allow higher velocities in makeup-airflow rates.

If makeup air can be managed, benefits of the exhaust design method include the ability to open adjacent zones to one another. Exhaust-method smoke-control systems also are easier to commission because they do not rely on the balancing of pressure differences.

Conclusion

Smoke-control systems have been required by building codes for decades. For much of this time, design criteria were straightforward. For the last 16 years, smoke-control design has focused on performance criteria based on the physics of fire. Applying the design methods found in current codes has posed some unique challenges. Often, the prescribed approach does not fit within a building's constraints. In these situations, designers are required to adapt or modify the design so the systems can prevent smoke migration effectively. During the last 16 years, HVAC professionals have learned how to meet building-code requirements effectively and adapt a design to meet a building code's intent.

Current smoke-control systems can be very effective in meeting building-code design criteria. Using pressurization or passive design methods, smoke-control systems can be effective in preventing the spread of smoke throughout a building. The exhaust method can help smoke-control systems be effective in creating a tenable environment. How the systems are adapted to a respective building depends on whether a practical approach has been used. The more elaborate the system, the more chances for failure. With practical application and design, code requirements — both prescribed and intended — can be achieved in today's buildings.

Vice president of growth markets for jba Consulting Engineers, Allyn J. Vaughn, PE, FSPE, LEED AP, has more than 28 years of experience in fire-protection and smoke-control-system design and commissioning. He has been responsible for third-party testing of smoke-control systems in Las Vegas for more than 13 years. Vice president of engineering for jba Consulting Engineers, Brad R. Geinzer, PE, LEED AP, has more than 20 years of experience in smoke-control-system design and commissioning. He was involved in the design and commissioning of the first Las Vegas building to use the performance-based criteria of the 1994 edition of the Uniform Building Code.