Smoke Control in a Non-ducted Return-air System

In a fire emergency, smoke and byproducts of combustion pose a far greater threat to human life than flames and heat. That is why, in modern construction, a considerable amount of attention is paid to ensuring a building is capable of limiting the spread of smoke in an emergency. Myriad systems and processes, including fire doors, smoke-detection systems, stairwell-pressurization systems, and exhaust systems, contribute to these designs, with many playing a major role in building HVAC and controls design. Obviously, systems that handle the movement of air play the biggest role in any attempt to control the spread of smoke within a structure. While an entire book could be written on this subject (and likely has been), this article will focus on a design challenge common in new buildings: designing for smoke control in a non-ducted return-air system above a suspended ceiling.

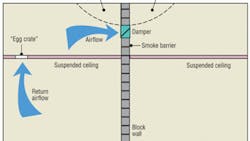

More specifically, this article will discuss large HVAC applications in which a good-sized unit or a group of units supplies treated air to various rooms via a network of supply ducts. The rooms and the corridors connecting them have suspended ceilings. Ductwork terminates at diffusers located within the rooms’ ceilings. “Egg-crate” openings in the ceilings of the rooms allow air to return above the ceiling space. While the rooms are separated from one another, there are openings in the walls between the rooms and interconnecting corridors. Ultimately, the space above the corridors’ ceilings becomes the main return-air path for the system.

As smoke-control standards are written, smoke is best detected on the return-air side of an HVAC system. However, if the return-air portion of a system has little or no ductwork, how does one detect that smoke is moving through the air in a fire emergency, particularly in the absence of a requirement for rooms to be equipped with smoke detection? We have seen many instances in which a mechanical engineer has specified the installation of dampers between rooms and corridors and the mechanical contractor has installed a type of fire damper utilizing fusible links in the openings.

Fusible links essentially hold open a spring-loaded fire-rated damper. The links melt when the temperature exceeds the temperature stamped on the links by the manufacturer. Once the links melt, the damper slams shut. There are several drawbacks to this. The first is there often is no supervision of the damper closing. A link may come loose, melt, or otherwise fail, and no one may be the wiser (aside from the fact the room may suffer improper air movement). A second drawback is if a link does fail, it must be replaced and the damper manually reset. The main drawback comes from a fire-safety and smoke-control standpoint. When the goal is to stop the spread of smoke, one has to ask what good are links that respond to heat only in dropping a fire damper. In most cases, by the time heat would build up enough to melt a link, smoke would have moved in an unintended direction.

So, if stopping the spread of smoke is the goal, selection of a motorized damper that is powered open is critical. Powering open a damper provides a fail-safe in that if the power feeding the damper drops out or otherwise is interrupted, the damper will, by design, naturally wind to the closed position.

Once a damper is selected, control must be established. Control is established by connecting the power that feeds a damper to relays controlled by detectors that can sense smoke movement.

At a high school recently, the entire area above drop ceilings was considered plenum space. Every classroom had a penetration through the wall above the drop ceiling to allow air from the rooms to move back into the spaces above the corridors. The walls were block, and the building did not have total smoke-detection coverage. The contractors were preparing to install fusible heat-link-style fire dampers in each of the openings when the code authority questioned the approach for the reasons outlined above. The code authority cited both local codes and the National Fire Protection Association (NFPA), including NFPA 72, National Fire Alarm and Signaling Code. The challenge was to have the return-air system comply with the following NFPA 72 requirement:

“Unless otherwise modified, ... if the detection of smoke in the return air system is required by other NFPA standards, detector(s) listed for the air velocity present shall be located where the air leaves each smoke compartment, or in the duct system before the air enters the return air system common to more than one smoke compartment.”

To understand where smoke detection needs to be positioned in this example, we have to refer to Appendix A of NFPA 72:

“Detectors listed for the air velocity present can be permitted to be installed at the opening where the return air enters the common return air system.”

The appendix goes on to explain where exactly to locate the detectors. This is shown clearly in Figure 2.

While the NFPA does a good job of describing where to locate detection, it does not provide a good explanation of how to accomplish it. Based on our interpretation of codes and standards, we have identified two ways to accomplish detection:

- The best approach from an overall fire-protection standpoint is to install a small length of ductwork on the outlet-stream side of every opening. This will give the fire-alarm installing contractor a place to mount a duct detector in the outlet-stream duct. By utilizing this approach, one stands the optimal chance of sampling and detecting smoke moving from room to corridor.

- Wire down from the ceiling spot-type smoke detectors rated for the anticipated air movement in compliance with NFPA mounting requirements for openings. A single spot detector is less expensive than a duct detector. If the opening is wide enough, multiple spot detectors may be needed. While this is not necessarily the best way to sample air moving from space to space, it does meet the intent of code.

Obviously, installing short sections of ductwork at every opening has its expense. Working closely with your fire-alarm-equipment vendor will help reveal which approach is more cost-effective from a smoke-detection-equipment standpoint.

Regarding connection to dampers, a relay base, a relay within a duct detector, and/or a relay module will cut the power feeding a motorized duct damper upon the detection of smoke. Also recommended is connecting the fire-alarm system to HVAC control equipment to shut down power to the HVAC system in the event of fire.

So, what method was chosen in our example? The high school went with duct extensions on each opening and added duct smoke detectors (approximately 100 in total). Everyone, including the local authorities, agreed this offered the best protection against the spread of smoke.

Utilizing the methods described here will result in a system capable of controlling the spread of smoke and that meets what the authors feel is the intent of codes and standards. It should be noted that, while the authors believe these methods to be sound, ultimately, it is the responsibility of authorities having jurisdiction to verify a planned approach fits their interpretation of the intent of applicable codes and standards.

Jeff Robinson and Todd VanGorder, SET, are system designers for Meridian Integrations (www.meridianintegrations.com). An Ohio board-certified fire-alarm designer, Robinson designs networked, voice-evacuation, and mass-notification systems for high-rise and specialty applications. He holds three National Institute for Certification in Engineering Technologies (NICET) certifications, including Level IV for fire alarms, as well as a degree in fire science. A former firefighter and emergency medical technician, VanGorder has more than two decades of fire-protection experience. He holds five NICET certifications, including Level IV for fire alarms and special-hazard fire systems, and is an Ohio board-certified fire-alarm and special-hazard-fire-system designer.

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].