Maximizing Condensing-Boiler-System Efficiency

Condensing boilers can be a highly efficient means of generating and circulating heat, as they recover latent heat from water produced during combustion and minimize cycling losses.

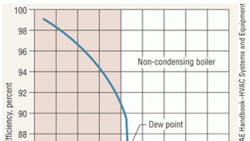

Figure 1 illustrates the relationship between heating-water return temperature (HWRT) and boiler efficiency. Low HWRT is required for high efficiency. This article will discuss how low HWRT can be achieved with industrial-grade pressure-independent control.

By optimizing heat-transfer performance at coils with pressure-independent control and matching thermal-energy production to load through better hydronic-system design, it is possible to heat more space with less energy, equipment, complexity, and cost.

RETROFITS

Any boiler will condense if the HWRT is low enough. A condensing boiler, however, is built to withstand the acid in combustion gases.

Although tens of thousands of facilities are likely candidates for condensing boilers, virtually none has the heating-water-distribution-system performance necessary for high efficiency. Figure 2 shows condensing-boiler-system performance — over a wide range of outside-air-temperature (OAT) and load conditions — in a laboratory facility in St. Louis. Note for how little of their operating time the boilers receive return heating water at a temperature low enough to condense.

In the system in Figure 2, the heating-water supply temperature (HWST) is on a typical linear reset schedule with the OAT. The distribution is designed for 30°F delta-T (ΔT) with 180/150 split coils, but achieves only 20°F ΔT at best. Pump speed varies from only 50 to 54 Hz. This means heating-water flow does not vary significantly over the range of load conditions. As a result of low ΔT (and near-constant flow), the pump variable-speed drives do very little to save energy.

That the HWRT in this facility is so high and the boilers rarely condense largely is a function of conventional-control-valve performance. Fortunately, typical coils have far more heat-transfer capability. With better flow control, ΔT performance can be improved dramatically. Low HWRT enables boilers to condense during the majority of operating hours.

Tables 1 and 2 show the expected performance of a typical air-handler heating coil. The coil is designed for an entering-water temperature (EWT) of 180°F, a leaving-water temperature (LWT) of 160°F, an entering-air temperature (EAT) of 55°F, a leaving-air temperature (LAT) of 92.28°F, and 20,000 cfm. Table 1 assumes the system is operated with a consistent 180°F supply-water temperature and no reset. Table 2 assumes a linear reset schedule between 180 and 140°F. Both tables moderately reduce LAT as load declines. As with any HVAC system, the majority of operating hours are at part load. This system should be expected to condense any time the load is less than 50 percent.

There are numerous condensing boilers on the market. Some may be limited to a maximum ΔT at full fire, while others may require constant flow and a primary/secondary (P/S) piping configuration. Additionally, there may be maximum supply-water-temperature or minimum flow requirements. Whatever the case, know that when coil flow control is optimized, part-load ΔT will rise significantly above design, and HWRT will drop, making it possible to dramatically increase the hours boilers condense in operation.

NEW CONSTRUCTION

With new construction, numerous steps can be taken to reduce both first costs and operating costs and deliver optimum environmental performance. In either a P/S or a variable-primary-flow (VPF) configuration, a minimum 60°F ΔT for piping and coil design significantly reduces pipe and pump size. With the application of pressure-independent control, lower HWRT enables boilers to operate at very high efficiency well into condensing mode.

Tables 3 and 4 show the expected performance of a high-ΔT heating coil. The coil is designed for an EWT of 200°F, a LWT of 140°F, an EAT of 55°F, a LAT of 90.60°F, and 20,945 cfm and sized to satisfy the same load as the coil in tables 1 and 2. Table 3 assumes the system is operated with a consistent 200°F supply-water temperature and no reset. Table 4 assumes a linear reset schedule between 200 and 140°F. Both tables moderately reduce LAT as load declines. This system, if piped in a VPF configuration, should operate in condensing mode the vast majority of the time.

Figure 3 shows a typical condensing-boiler system in a pressure-independent VPF configuration, the system design that should be used with condensing boilers that can handle variable flow and condensation on the primary heat-transfer surface. Pressure-independent control valves are installed at each heating coil in lieu of conventional two-way and balancing valves. Bypass valves are used to augment flow through boilers if a minimum flow is required to prevent a trip at the high-temperature limit.

Pump speed is controlled at the most hydraulically remote point(s) to maintain the 5-psid minimum required for pressure-independent control and high ΔT. This reduces the number of installed pumps and minimizes the blending of supply and return water.

P/S piping should be used with condensing boilers built with a secondary heat exchanger used to condense flue gas (figures 4 and 5). Boiler efficiency is reduced with significant flow in either direction through a bypass. Supply-water bypass into a return raises boiler HWRT. Similarly, return water blending with supply reduces coil capacity and raises HWRT.

In P/S configurations, pressure-independent control valves also are installed at each heating coil in lieu of conventional two-way and balancing valves. Also, secondary-pump speed is controlled at the most hydraulically remote point(s) to maintain the 5-psid minimum required for pressure-independent control and high ΔT. In this configuration, blended hot return water drives boiler efficiency. Care should be taken to operate plants in a way that minimizes bypass flow. Maximizing load puts the bulk of generated heating water through coils.

INDUSTRIAL-GRADE PRESSURE-INDEPENDENT CONTROL VALVES

A pressure-independent control valve (Figure 6) is fundamentally different than a conventional two-way-control-valve/flow-limiter combination. With an actuator, it is applied at air-handler and terminal-unit coils to control the water flow necessary to meet a supply-air or space-temperature set point, just like a conventional control valve. The difference is that the flow through a coil served by a pressure-independent control valve does not vary as system pressure varies. This is because the differential pressure across the control surface (P1 to P2 in Figure 6) remains low and constant (2 to 3 psid), regardless of the pressure across the entire valve. Flow rate changes only when the valve stem rotates. It is properly sized in the hydraulic gradient by coil design flow rate alone. High rangeability with better sizing enables it to modulate well at low loads and flows.

Pressure-independent control valves enable optimized coil performance, high ΔT, and condensation for a significantly longer time than conventional valves. Also, they reduce simultaneous heating and cooling. With large pistons, springs, and flow passages, they are highly stable and resistant to debris, while industrial-quality materials enable them to withstand hot fluids and water-treatment chemicals.

Pressure-independent control helps reduce the demand for heating- and chilled-water flow at air-handler and terminal-unit coils. When coil heat transfer is enhanced, less water flow is required to satisfy a load. In a heating-water system, this means low return-water temperature and boilers that condense. System design is simple. No reverse return piping or balancing valves are required.

HWST RESET

Resetting HWST may lower boiler- and distribution-system heat loss and increase tolerance of poor control. Conversely, with better control, consistently hot supply water may consume less energy, reduce HWRT, and more effectively manage morning warmup. Following are design choices and energy trades worth additional consideration:

-

At a supply-water temperature of 180°F, 5-percent leakage can kill system performance; at 120°F, it is not nearly as detrimental. Conventional control valves typically are not selected with tight shutoff. They get dirty and wear over time. Leakage increases and contributes to simultaneous heating and cooling.

Conventional control valves typically are sized by rule of thumb (5 psid, same pressure drop as the coil served, one line size smaller than the pipe, etc.). This leads to control valves that are poorly sized in the hydraulic gradient. They do not modulate well, particularly at low flow, and typically are installed with flow limiters that guarantee poor ΔT performance. HWST-reset schedules drive down ΔT and increase flow, masking poor equipment performance.

-

The hotter the water, the greater the heat loss at boilers and in pipes. Are reductions in boiler and pipe heat loss offset by added pump and fan energy consumption? How good is the insulation? In heating mode, does heat make it into the space anyway? In cooling mode, do heating and reheat valves leak, leading to simultaneous heating and cooling?

-

Lowering HWST reduces ΔT and increases flow. The greater the flow, the greater the pump energy consumption. Lowering HWST also may reduce LAT. The colder the air, the greater the airflow and fan energy that may be required to satisfy space temperature requirements.

-

CONCLUSION

Condensing boilers offer outstanding opportunities for conservation; however, typical distribution-system performance (and high HWRT) can adversely impact final results. With modern technology and a systems approach to optimizing the production, distribution, and use of heating water, condensing-boiler systems can be designed to realize their full potential.

There are numerous successful distribution-system projects using industrial-grade pressure-independent control, primarily in the large-commercial and institutional HVAC and district-energy markets. All are designed to maximize heating- and/or cooling-coil performance.

When properly applied, condensing boilers and pressure-independent control are easy for operators to understand. Components can be selected to deliver high performance for the life of a facility, even as it expands. High ΔT generates savings and creates opportunities for additional conservation and performance enhancement.

Whether for a new facility or an existing one, condensing-boiler systems with pressure-independent control can achieve high performance. These should be seen as investments for facility owners seeking to save energy, minimize costs, and reduce emissions.

Eric Moe, MSE, MBA, has 17 years of experience in mechanical-system design and integration. He is an active member of the International District Energy Association and the Association of Energy Engineers. Formerly, he served as director of business development for Flow Control Industries Inc. He can be contacted at [email protected].

Condensing-Boiler Tips

Following are best practices to help you get the most out of your condensing boilers:

Get out of the boiler room

A key to very high efficiency is low HWRT, which enables boilers to operate the majority of time in condensing mode. Optimization takes a systems approach that considers production, distribution, and demand for hot water.

Know your heating and reheat coils

Get familiar with a common coil-rating and selection program. Assess the capability of the distribution system to deliver low HWRT. Be sure to consider the effect of HWST reset and lower LAT. When coils and control valves are operating together properly, higher HWST produces lower HWRT. Lower LAT increases ÄT, but also increases airflow.

Use industrial-quality pressure-independent control valves at coils

Industrial-quality pressure-independent control valves maximize heat-transfer performance at coils and deliver high ΔT for the life of facilities. High-temperature capability, debris tolerance, and availability of parts are a few reasons why industrial-grade pressure-independent control valves are so cost-effective in the long run. No balancing valves are required, and Y-strainers are not needed at every coil.

Carefully consider whether HWST reset is necessary

Take into account total-system energy use when planning a control strategy. Be sure the boiler will condense, but minimize total energy consumption. Consider driving up HWST at peak load to maximize system efficiency and available capacity.

Design new projects for at least 60°F ΔT

Be sure to consider boiler capabilities when choosing a piping configuration. Use pressure-independent control at heating coils, and eliminate reverse return and balancing valves. Bear in mind that 60°F-ΔT coils generally cost no more than 20°F-ΔT coils, while the pumping and piping expense can be considerably less.

Specify and verify performance

Conventional two-way valves, balancing valves, and variable-frequency drives do not optimize performance. After installation, startup, and commissioning with industrial-grade pressure-independent control valves, verify that the distribution system is performing as intended by trending data as shown in Figure 2. Boilers should condense, space temperatures should be satisfied, and total-system energy consumption and emissions should be minimized.