How Modern Hot Water Systems Can Lower Campus Energy Use

By Dr. ISHAI OLIKER, PE

Joseph Technology Corp.

Montvale NJ

In the United States, the beginning of district heating (DH) can be traced back to the late 18th century when Benjamin Franklin sold heat to several adjacent residences in Philadelphia. Almost one hundred years later in 1877, Birdsill Holley designed the first financially successful DH system in Lockport NY. This system, based on the delivery of steam, was widely imitated. By 1887, 20 DH systems were in operation in the United States. Co-generation was introduced as early as 1890.

After these early attempts, wider introduction of the systems began in the beginning of the 20th century. The purpose was to rationalize ways of heating clusters of buildings from a central power plant or a boiler plant through a suitable distribution medium. In the United States, the distribution medium was steam, while in Europe, the predominant distribution medium was hot water.

Today, most district heating systems owned by universities in the United States use steam or high temperature water for heat supply. In this article, we concentrate on comparing steam-based systems with low temperature hot water systems (with temperatures below 250F).

Advantages of low temperature district heating systems versus steam are as follows:

• Substantial reductions in heat losses in the distribution system (3-5% for water v. 15-20% for steam). A hot water system eliminates the heat losses from steam traps, valve stems and packing gland leakage, blowdown and flash losses;

• Use of hot water allows for the generation of more electric power in a cogeneration facility;

• Superior heat storage characteristics. In a hot water system, a large volume of water provides a continuous heat reservoir available to handle peak demands or swings in load;

• Flexibility of piping distribution systems. Since a hot water system uses forced circulation, the piping lines can follow the contours of the ground or the building, as the heating medium remains liquid. Steam and condensate return lines require a certain degree of pitch for drip legs, traps, etc.;

• Closed hot water systems have practically no make-up requirements. The only unavoidable losses are minor leakage at pump glands and valve stems;

• A steam system can require from 1 to 100% make-up depending on the type of condensate return system and water quality. Many old steam systems are not equipped with condensate return piping. Losses from blowdown and condensate necessitate significant make-up involving an expensive chemical and deaeration treatment facility;

• Closed hot water systems have a relatively corrosion-free environment after initial chemical treatment; a steam system’s condensate return is notorious for corrosion problems;

• Lowered maintenance. In a hot water system, the heat medium stays in a liquid state. Thus there is no need for pressure reducing stations, condensate receivers, traps, drip legs, deaerating feed water heaters, etc., as with a steam system. Maintenance problems associated with steam traps alone are quite significant;

• Safety. Hot water is less dangerous than steam. Steam transport systems periodically experience water hammer events with deplorable consequences;

• Better temperature control. A hot water generator operates with variable supply temperatures and flow rates closely following the demand. Hot water yields a more uniformly distributed temperature in the building.

The existing university district heating systems typically use medium pressure steam (supply pressure 60-150 psi) or high temperature hot water (supply temperatures 350-400F). To withstand the high media temperature, the systems typically use factory-fabricated conduits with air space and steel jacket or concrete trenches with field-fabricated piping. These systems require manholes, anchors and expansion devices with associated high capital and O&M costs. In wet underground environments, the external steel jacket of the conduits is subject to intensive corrosion and perforation.

Underground water penetrates the annular area of the conduit, wets and destroys the insulation and causes high heat losses. Similar situations often take place in the concrete trenches. Water infiltrates pipeline channels from the outside and high ground water causes external corrosion when pipe insulation material becomes wet and ventilation in pipeline channels is poor. To prevent internal corrosion, an effective and expensive chemical treatment of the make-up water is required.

University District Heating Hot Water System

One university was equipped with a campus-wide, district steam system installed in a walk-through concrete tunnel, three miles long, in 1904. The district steam at 60 psi was supplied from the physical plant equipped with gas-fired steam boilers. Steam was used for space heating, domestic hot water for the campus buildings, and absorption chillers. The piping system in the tunnels had deteriorated from internal corrosion and required continuous steam leak repair.

Overall, the district steam system supplied 28 campus buildings with space heating and domestic hot water. Fourteen of these buildings had internal hot water heating systems which were supplied by the district steam system through steam to hot water heat exchangers. The rest of the buildings had steam heating systems supplied directly by district steam.

In order to substantially reduce steam losses in the district steam system, JTC proposed to convert the entire campus to a central hot water system, which will supply all buildings with hot water. Considering that the existing district steam system had to be replaced in the next few years, the following modifications were proposed. In the first stage, the physical plant was equipped with steam to hot water heat exchangers and variable speed hot water pumps. A new low temperature hot water piping distribution system was installed in the tunnels in parallel with the existing steam system. The existing tunnel system had enough space for the installation of the new hot water system.

In the first stage, the hot water system supplied water to the buildings which had inside hot water systems. The hot water bypassed the existing steam to heat exchangers and supplied water directly into the building systems.

In the second stage, the hot water distribution system was extended and connected with individual boilers. The steam buildings are gradually retrofitted to hot water and also connected to the hot water distribution system. The existing building’s hot water pumps were shut down.

Installation of Hot Water System at the Jamestown Community College

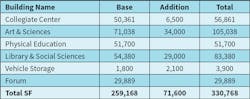

Extensive experience has demonstrated that the average seasonal efficiency of individual boilers is 57% (Rev. 1-4). Therefore, interconnection of individual buildings into a hot water district heating system allows the existing boilers to operate with much higher efficiency. The example of such interconnection is the Jamestown Community College (JCC). The JCC campus consisted of six buildings equipped with individual boilers (Table 1).

In order to reduce energy consumption of the buildings, JTC proposed to connect them with a low temperature hot water district heating underground piping (Figure 1).

The supply of hot water was centralized and the boilers were staged for the most efficient operation reducing the total fuel cost. The most efficient new boilers were at the Collegiate Center (COCE). A steam to hot water heat exchanger was installed at this building and hot water was used for base load supply to all buildings, increasing the seasonal efficiency of the boilers. The boilers in the other buildings were used for intermedium and peak load operation of the total system. The Vehicle Storage building was converted to hot water. The system also recognized a substantial boiler back-up capacity.

When the buildings were initially hooked up, the total square footage of the campus was about 260,000. Since then, additions to buildings of the JCC have expanded the total area to 330,000 square feet (Table 2). Even with a 27% increase of square footage, no additional boilers were required to meet heating needs.

Connecting JCC with district heating piping offered substantial savings over individual boiler operation. Before district heating was installed, fuel data showed an annual normalized consumption of 23,800 mmbtu, or specific consumption of 0.01918 mmbtu/sq.ft.

When this value is multiplied by the total increase in square footage from building additions (71,600 sq. ft.), an additional fuel consumption of 6,575 mmbtu would have been required, bringing the total annual fuel consumption without district heating to 30,375 mmbtu.

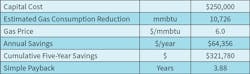

The five-year normalized average fuel consumption of JCC with district heating was 19,649 mmbtu. Therefore, the introduction of district heating resulted in annual fuel savings of 10,726 mmbtu. These savings have accumulated into almost 50,000 mmbtu over the five-year life span of the district heating system. Operating with gas prices of $6/mmbtu, JCC has realized over $300,000 in savings since the building interconnection was first implemented. The payback period for the installation of the district heating system was found to be less than four years (Table 3).

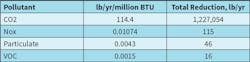

Interconnection of the individual boiler systems into the district heating system also allowed the project to recognize important environmental benefits. Table 4 shows the extra emissions that have been avoided because of the lower gas consumption of the district heating system.

The described conversion of individual boilers to a centralized hot water system can be replicated in many universities.

Conversion of Steam-Based Systems to Hot Water

Operational experience demonstrates that the retrofit of steam-based systems to hot water operation with variable flow and temperature regime offers system efficiency improvements in the range of 25 to 40%. A key method for improving the competitiveness of DH is the retrofit of steam DH systems to low temperature hot water and increased use of combined-heat-and-power production (CHP). CHP increases efficiency of primary fuels’ use by 25-30% compared to condensing power production and heat-only boilers. In many sites, this retrofit has a significant positive impact on ambient air quality.

Conversion of steam based systems to hot water is performed in a gradual fashion and requires substantial time and investment. When all operational problems are evaluated, the retrofit is economically justified. The list of retrofit components include the following:

• Heat exchangers, radiators, convectors, fin-tubes and air handling systems;

• Humidification, kitchen, sterilization and other process steam systems;

• Control and metering systems;

• Conversion construction procedures;

• Efficiency improvement evaluation.

Both direct and indirect consumer connections are used. In direct connections, the water circulating in the DH network is introduced directly to the consumer installation. In systems with direct heat supply, the DH water flows into the building’s secondary circuit (radiators).

Consumer connection are usually indirect. This means heat is transferred from the DH networks by means of heat exchangers to the internal heating networks of the buildings. This results in hydraulically separated DH and building heating systems.

In small systems, direct connections are used, whereby water from the DH network is transferred directly to the internal heating network of the building and radiators. Heat meters are typically installed in each building. In some instances, the supply steam piping can be used for hot water supply.

Other considerations:

• Installation of high-efficiency cogeneration systems;

• Use of multiple fuels including renewables like biomass;

• Introduction of modern automation and building control systems.

References

Smith, W.A., “The Myth of the 80% Efficiency Boiler System”, Proceedings of the IDHCA, 1987.

Tierney, T.M. and Fishman, C.J., “Real World Boiler Efficiency”, Proceedings of the IDHCA, 1987.

Reisdorf, J., “Seasonal Efficiency of Relatively New Building Boiler System”, Proceedings of the IDHCA, 1988.

Landry, R.W. Maddox, D.E., Lobenstein, M.S, and Bohac, D.L. Measuring Seasonal Efficiency of Space Heating Boilers. ASHRAE Journal, September 1993.

Licensed in 10 states and active for more than 30 years, the author is president of Joseph Technology Corp. and former president of the International District Energy Association. He has extensive experience in district heating, cooling and CHP development projects in the U.S., former Soviet Union, Korea, and China. Contact Dr. Oliker at 201-573-0529, or via e-mail: [email protected].