Air-filtration technology has evolved tremendously since the advent of air filtration during the 1930s. The air-filter-selection process has evolved as well, not only protecting HVAC equipment, but protecting building occupants, reducing energy consumption, and minimizing environmental impacts.

With a variety of filtration technologies and styles to choose from, as well as industry-standard criteria for judging filtration performance, engineers now can select air filters to maintain HVAC-system cleanliness, improve indoor-air quality (IAQ), and reduce energy consumption simultaneously.

A HISTORY

Air filters were developed for use in the forced-air heating systems that were popular in commercial buildings during the 1930s. The filters primarily were designed to reduce the risk of building fires by protecting HVAC-system heating elements from dust. At the time, air filters consisted of loose mats of fibrous glass, animal and synthetic fibers, metal mesh, and various fabrics of cellulose and other porous materials.

As air-conditioning systems became more prevalent in commercial buildings during the 1940s and 1950s, filters were used more for HVAC-system hygiene, protecting cooling coils from dust and preventing fouling. These filters were made with the same materials used in the industry's earliest filters.

During the 1980s and 1990s, public concerns about IAQ began to emerge. The filter industry started to look at a filter's ability not only to protect HVAC equipment, but to clean air streams. During this period, the industry developed standard methods for testing filtration efficiency. With the advent of ASHRAE Standard 52.2, Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size, minimum-efficiency reporting values (MERVs) became the accepted method of comparing filtration efficiencies over a range of particle sizes.

Today, air filtration is even more evolved. Fueled by various green-building initiatives and rising energy costs, commercial and institutional facilities are casting a more critical eye toward the roles air filters play in energy conservation, sustainable building design, and occupant health and productivity. Also, the terrorist attacks of Sept. 11, 2001, and the anthrax incidents that followed have created a focus on the use of air filters as protection against chemical or biological attacks.

HOW FILTERS WORK

There are four primary methods of particle capture for particulate air filters:

Straining

Straining occurs when a particle is larger than the opening between fibers and cannot pass through. It is an ineffective method of filtration because the majority of particles are smaller than the spaces between fibers.

Inertial impaction

Also called impingement, inertial impaction describes the capture mechanism of large, high-density particles. As air flows through a filter, it must make adjustments and change direction to flow around the filter's fibers. Large particles resist changes in an air stream's direction, and their inertia causes them to collide with and remain attached to a filter-media fiber.

Interception

Interception occurs when a particle follows an air stream, but comes in contact with a fiber. If the forces of attraction between a fiber and a particle are greater than the air stream's velocity, the particle will adhere to the fiber. Interception is enhanced when the sizes of a fiber and particle are comparable.

Diffusion

Diffusion takes place when very small particles are influenced by molecular collisions (called Brownian movement), causing a particle to strike a filter-media fiber at random and remain attached by van der Waals force.

AIR-FILTRATION EFFICIENCY

The first step in determining the best type of HVAC filter for a particular facility or application is to consider the conditioned space's activities and the types and sizes of particles those activities generate.

Removal of all airborne contaminants is not practical in most cases, so once problematic pollutants are identified, a filter's efficiency can be selected. Filtration efficiency defines how well a filter cleans indoor air by removing airborne particles.

Particle-capture efficiency is the primary performance indicator for HVAC filters. Once particle-capture efficiency is specified, other filter characteristics should be reviewed and compared to improve cost in use, such as a filter's resistance to airflow, which is proportional to the energy consumed by the filter. Energy expenditures can account for about 81 percent of an air-filtration system's annual operating costs, while its purchase price and maintenance can account for about 18.5 percent. The filter's recommended life should be a factor because of replacement-product and labor costs. The use of filter-media fibers that do not absorb moisture or shed also should be considered.

continued

ASHRAE STANDARDS

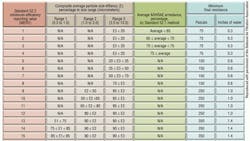

The 2007 version of ASHRAE Standard 52.2 quantifies the fractional particle-size efficiency of filters at various particle sizes. A test indicates a filter's ability to remove airborne particles with diameters between 0.3 and 10 microns (Table 1).

A MERV is assigned to a filter depending on particle-size efficiency in three particle-size ranges: 0.3 to 1 micron, 1 to 3 microns, and 3 to 10 microns. MERVs range from 1 to 16, but high-efficiency-particulate-air (HEPA) filters, which have MERVs of 17 to 20, are tested with different standards. For general HVAC applications, a MERV of 1 is least efficient, while a MERV of 16 is most efficient. Recent studies suggest that a MERV of 8 is enough to provide good HVAC-system cleanliness and efficient operation, even though the current minimum requirement, according to ASHRAE Standard 62.1, Ventilation for Acceptable Indoor Air Quality, is a MERV of 6.

In addition to MERVs, it is important to review fractional particle-size-efficiency curves. These curves show a filter's efficiency in capturing particles of a specific size at a particular airflow rate. Keep in mind that MERVs designate the minimum efficiency at which a filter will perform.

FILTER TECHNOLOGIES AND STYLES

There are many styles of HVAC filters on the market, but only a few types of commonly used filter media.

Some commercial facilities continue to use older flat-panel filters with filter media made of spun glass or high-loft nonwovens. These often are called “throw-away” filters. They typically capture particles through straining and impaction. These filters typically have MERVs of 5 or below and efficiency values of less than 35 percent for particles in the 3-to-10-micron range. That means more than 65 percent of particles in that range, plus virtually all smaller particles, pass through the filter without being captured.

Pleated filters commonly are made with a blend of cotton/polyester or synthetic media. Pleating of the media provides a larger filter-surface area than panel filters. Most pleated filters have MERVs of 6 to 11, with filter-media depths of 1, 2, or 4 in. These filters use a combination of straining, impaction, interception, and diffusion to capture particles. Depending on the filter, capture efficiencies for particles in the 3-to-10-micron range can be 35 to 85 percent. These filters are common in most commercial buildings.

Extended-surface filters also are made with synthetic media or fiber-glass or cellulose/glass-fiber blends. They include bag or pocket, rigid-cell, aluminum-separator, and V-bank filters. Most have filter-media depths of 12 in., although media in pocket filters can be up to 30 in. deep. Pocket filters offer an even greater filter-surface area than pleated filters to provide maximum efficiency with the lowest pressure drop and longest life. Pocket filters use a combination of straining, impaction, interception, and diffusion to capture particles and typically have MERVs of 11 to 15, capturing up to 95 percent of particles larger than 3 microns. Each filter has unique properties related to its rigidity, airflow resistance, and service life and should be compared on a case-by-case basis.

In most commercial buildings, a MERV 8 pleated filter is the recommended minimum. In some buildings, it may be appropriate to use a medium-efficiency pre-filter and a high-efficiency extended-surface filter. The major advantage of using a pre-filter is to extend the life of a high-efficiency filter. In the absence of pre-filters, high-efficiency filters may load with large particles quickly, causing airflow resistance to increase. This can increase the load on system fans and, in extreme cases, induce filter bypass because of leakage at joints in the HVAC system.

The goal of filter installation is to avoid bypass air, which remains unfiltered because it bypasses the filtration media. This unfiltered air contains particulate matter that contaminates housings, coils, fans, and ducts. Bypass occurs when filter media is not sealed properly in the filter frame, when filters are not gasketed properly in filter racks, or when air-handler doors and ducts are not sealed properly.

Gaps around high-efficiency filters or filter housings can decrease filter performance. For a 1-mm gap, bypass flows may be less than 5 percent of the total airflow; for a 10-mm gap, bypass flows can increase to 25 to 35 percent of the total airflow. Air, like any gas or liquid, will flow through the area with the least resistance. Because higher efficiency filters have a larger resistance to airflow, bypass air has a larger effect on high-performance filters.1 Also, bypass air reduces MERVs. Mathematical models have shown that a 1-mm gap causes a MERV 15 filter to perform as a MERV 14 filter, while a 10-mm gap causes a MERV 15 filter to perform as a MERV 8 filter.1

CONCLUSION

Effective air filtration provides the primary defense for building occupants and HVAC equipment against particulate pollutants generated within a building as well as pollutants from air drawn into a building from an HVAC system. Because indoor air can be two to five times more polluted than outdoor air, HVAC engineers would be well served to learn more about proper filter selection.

REFERENCE

-

Ward, M., & Siegel, J. (2005). Modeling filter bypass: Impact on filter efficiency. ASHRAE Transactions, 111, 1,091-1,100.

David Matela, CAFS, is a market manager with Kimberly-Clark Filtration Products, a supplier of HVAC filter media. He has worked for the company for 11 years, during which he has been involved in consumer-product development and nonwoven-material and process development, areas in which he holds eight patents. He can be contacted at [email protected].