VAV + IEQ: Cure For the Common Cold

By C. MIKE SCOFIELD, P.E., North Bay Operations, Conservation Mechanical Systems, Sebastopol CA.

In cold-dry Northern climates, Indoor Environmental Quality (IEQ) can be destroyed by over ventilation with outdoor air and artificially high Air Change Rates (ACR) in winter. This is often why we catch the Flu during the winter when indoor environments drop below 40% Relative Humidity (RH). This is certainly true in office space and classrooms.

Airborne pathogens that spread the Flu remain buoyant and viable for longer periods in the human breathing zone indoors in dry atmospheres below 40% RH. Artificially high ACR can cause turbulence in the human breathing zone, which spreads the pathogen further from the human host. For reasons not yet fully understood, the airborne pathogen becomes more virulent in dry indoor conditions.

It has become incumbent on HVAC design professionals not only to provide a comfortable indoor building environment in winter, but a healthy indoor environment, as well. Proper indoor humidity control is often shunned by consultant engineers because of the added energy costs to the owner to humidify buildings in cold Northern climates. The maintenance for -- and control of -- humidification equipment is both difficult and expensive. Therefore, indoor humidity control is often eliminated from the HVAC design.

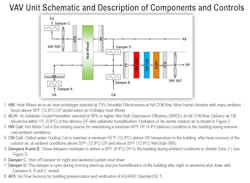

Figure 1 (below) shows a Variable Air Volume (VAV) Central Station Air-Handling Unit (AHU) schematic of a design concept that uses an Adiabatic Cooler/Humidifier (AC/H) system and Heat Wheel heat recovery device to recover heat from the building Return Air (RA) to hydrate all outdoor air entering the building, then to be delivered to overhead diffusers inside the building.

VAV terminal boxes with reheat may then be setup to deliver the minimum room CFM flow to meet the requirements of ASHRAE Ventilation Standard 62.1 or Code requirements. Reheat may be added at the zone terminal box without energy waste since Code outdoor air is being furnished. The low Supply Air (SA) temperature at a minimum Dew Point (DP) of 40 F will insure room acceptable RH between 40% to 55%. (see Figure 2). Fan energy will be reduced in winter due to the reduced room ACR. Room thermostat set point temperature in cold weather may be set lower, saving reheat energy, since humans perspire less at 40% RH giving the perception of comfort at lower room Dry Bulb (DB) temperatures. In Northern climates, South-facing glass, in offices at the building perimeter, can produce zone-maximum cooling loads which can be satisfied with considerably less CFM when the delivery DB is 40°F in lieu of 55 F.

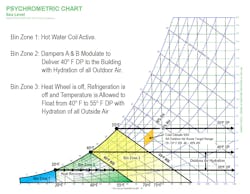

The Psychrometric Chart (Figure 2) shows the heat recovery and adiabatic humidification process lines where ambient conditions have been segregated into Zones 1, 2 and 3. The very simple control strategy is for the unit to provide a minimum winter DP of 40°F to the building during cold outdoor temperatures. Since, at low CFM flow in winter, the AC/H has a higher saturation efficiency, the DB delivery temperature, which will be within 1°F of the supply air DP, may be used to control the AC/H process. Low cost Commercial Grade DB temperature sensors are accurate and repeatable where DP sensors are not. At the saturation curve in Figure 2, the DB temperature=WB temperature=DP temperature.

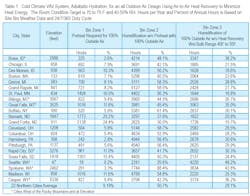

Zone 1 in Figure 2 includes the ambient conditions that are so cold that the heat generated inside the building by people, lights and plug load is not adequate to deliver a 40°F DP to the building. The pre-heat coil must be active to reach a 40°F Wet Bulb (WB) condition that the AC/H may use to generate the required 40°F DP delivery condition. For the 22 cities studied, there is only an average of 9.19 % of the annual hours in this zone where pre-heat or re-heat is required. (see Table 1).

Zone 2 shows the hours per year when a sensible Heat Wheel will deliver the 40°F WB required for the AC/H to furnish the 40°F DP to the building without any added pre-heat or re-heat of the outdoor air. For the average of the 22 cities, there are 50.7% of the annual hours in this zone (See Table 1). Zone 3 contains all of the ambient hours per year when the heat wheel may be shut down and it’s supply-side parasitic static pressure loss shunted out of the system. Refrigeration is also off and sensible cooling may be generated with Energy Efficiency Rations (EER) approaching 100. Delivery DB to the building is allowed to float up from 40°F to 55°F and VAV supply CFM is allowed to increase as required to meet cooling loads called for by the VAV terminals inside the building. For the 22 cities , there are an average of 29.1% of the annual hours within Zone 3 in Table 1.

For many years after its introduction in the 1970s, VAV and IEQ have been two mutually exclusive acronyms. Proper maintenance of outdoor air ventilation rates and indoor air humidity were non-existent. Overcooling was endemic. Adiabatic Cooling and Humidification coupled to Heat Recovery offers a cost effective solution to poor Indoor Environmental Quality. As one author in a recent ASHRAE Journal article put it, “It’s time to Make VAV Great Again!”

An ASHRAE Fellow and longtime registered professional engineer, the author is president of the North Bay Office of Conservation Mechanical Systems Inc. He has authored many technical articles on the use of direct and indirect evaporative cooling to reduce peak cooling energy demand and to improve IAQ with 100% outdoor air systems, especially in arid, Western U.S. climates.