Aerodynamic Containment Can Reduce Indoor Spread of Infectious Aerosols

The current pandemic has elevated the awareness for better Indoor Air Quality (IAQ) and ventilation.

Often good ventilation is referred to as high-grade filtration with an increased supply of clean air or increased air change rates per hour (ach, h-1). However, simply increasing the supply of clean air may not be sufficient to achieve good ventilation. The primary goal of building ventilation is to create a healthy and comfortable environment for building occupants.

That can be achieved by supplying clean air to dilute the concentration of airborne contaminants, thereby, reducing the risk of airborne infection and hazard. The breathing zone of occupants, which is generally between 4 to 6 feet (1 to 2 m) height from the floor, is the most critical zone in which occupants breathe in and out.

But the sources of contaminants and receptors both are located in the same zone. Therefore, the ventilation design should ensure that the clean filtered air is properly distributed in the breathing zone and the contaminated air is effectively removed from this zone.

Airflow Patterns Matter!

Air is the primary carrier of heat, moisture, and airborne contaminants including infectious aerosols in indoor spaces. Therefore, how air moves in indoor spaces and whether it properly sweeps the contaminants become the most critical factor to consider.

Indoor airflow patterns play a crucial role in controlling the spread of airborne contaminants. The flow path of airborne contaminants depends on the airflow patterns. Poor airflow distribution in indoor spaces can spread infectious aerosols and make social distancing less effective.

Ideally, the clean supply air should sweep the contaminants from the breathing zone without significant recirculation and stagnation that usually promote the buildup of high- concentration zones. Similarly, the clean air should not escape or short-circuit the space without collecting and removing contaminants from the breathing zone.

Several factors related to the design and operation of HVAC systems can impact the airflow patterns in indoor spaces and the risk of infection. Some of these factors include the number, location and type of supply diffusers in the space; supply airflow rates (air change rates) and associated diffuser throws; supply air temperature; number, size and locations of return/exhaust grilles; the location and strengths of various heat sources in a room; an arrangement of furniture and other obstructions to airflow; location, type and capacity of in-room air cleaners; and, importantly, the relative positions of contaminant sources in space.

Air often follows a path of least resistance, which, however, is generally not intuitive.

Computational Fluid Dynamics (CFD)

Physical testing and real-time measurements of all the parameters that affect the ventilation performance are often both time-consuming and labor-intensive, if not impossible. Moreover, such measurements are not even possible during the design phase before the construction of a facility.

In such situations, CFD analyses provide a feasible tool to visualize the airflow patterns and the flow path of airborne contaminants, and thereby, optimize the performance of building ventilation. CFD involves the simulation of fluid flow, heat transfer, mass transfer, and other similar transport processes which are based on the fundamental laws of Physics of transport mass, momentum, and energy.

CFD analyses, if performed properly with adequate expertise, can provide valuable insights into the heating, cooling, and ventilation performance of buildings. Such insights gained during the early stages of the design can save expensive, trial-and-error, and often frustrating retrofits.

Aerodynamic Containment Layout

We used CFD to develop a concept of aerodynamic containment. The strategic layout of supply diffusers and exhaust grilles can form airflow patterns that can help reduce the risk of contaminant exposure in indoor spaces. Distributed supply and distributed exhaust in indoor spaces can help in better utilization of the clean supply air. It can enhance dilution in the breathing zone of occupants; provide a path of least resistance for the contaminated air to leave the space; and reduce the probability of infection.

Aerodynamic containment is a symmetric layout of distributed supply (diffusers) and distributed return (grilles) which can contain the contaminants in the vicinity of a source and can limit the spread of airborne contaminants in indoor spaces.

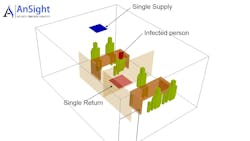

Our CFD studies demonstrate that even for a simple layout of a small office with two cubicles, the locations of supply and return air can affect the airflow patterns and the resulting risk of infection for the occupants. A layout in Figure 1a (above, left) with just a single 4-way supply diffuser and a single return grille cannot provide adequate dilution and promote air recirculation and the formation of stagnant zones with a high concentration of contaminants.

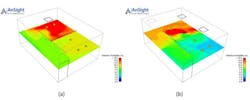

The airflow patterns in Figure 2a (above, left), show large recirculation loops along and across the room. These large recirculation zones are formed inside the cubicles between the room walls and the dividing partitions. The stagnation of air in the recirculation zones forms pockets of high concentration. We used the Wells-Riley correlation to determine the risk of infection.

As shown in Figure 3a (above, left), the risk of infection is above 15% in the vicinity of the infected individual, whereas the average probability of infection at the breathing plane is 11.3%.

We developed a new metric for ventilation effectiveness called the Spread Index which analyzes the extent of the spread of contaminants in indoor spaces.

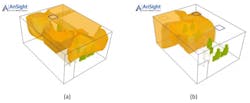

As shown in Figure 4 (below), the Spread Index of 10% probability of infection is 49.4% indicating that about half of the space is at or above a 10% probability of infection. It should be noted that all occupants in this space are covered under the cloud of the high risk of infection.

Whereas the aerodynamic containment layout as shown in Figure 1b with the distributed supply diffusers helps with better distribution of clean air. Distributed return grilles provide a path of least resistance for the contaminated air to leave the space, and the symmetric layout of supply and return grilles forms airflow envelopes that promote local containment of the airborne contaminants.

As shown in Figure 2a, the aerodynamic layout forms independent zones of airflow and develops two identical, mutually opposite airflow patterns within each zone of supply and return.

As shown in Figure 3b, the risk of infection is reduced in the second cubicle, and the zone of high infection above 15% remains in the vicinity of the infected individual. The average value of the probability of infection reduced from 11.3% to 9.1%. The Spread Index as shown in Figure 4b reduced from 49.4% to 39.3%. Unlike the previous cases, only about one-third of the room space is at or above 10% probability of infection.

Dividing the supply air through two diffusers created two distinct aerodynamic containment zones. The airflow patterns from each diffuser create their zone of containment, which minimizes bi-directional air movement between the zones. Providing returns for each zone reduced the long travel of contaminated air through the occupants.

Additionally, moving the supply diffusers away from the returns helps sweep the clean air through occupied zones. Such aerodynamic containment with a symmetric layout of distributed supply and distributed return alters the flow path of contaminated air and moves it away from the occupants.

Since the location of an infected individual in a room is not known in advance, such aerodynamic containment strategy can potentially reduce the risk of cross-contamination.

Designing for Aerodynamic Containment

Based on our CFD analyses, aerodynamic containment requires the following steps:

- Create a distributed supply layout by increasing the number of supply diffusers (without increasing the supply airflow rate) and strategically placing them over the occupied zone;

- Create a distributed return layout by increasing the number of exhaust outlets to create a path of least resistance for the contaminated air to exit the space;

- Place the exhausts/returns away from the occupied zone;

- Create a symmetric layout of supply diffusers and return grilles to form independent airflow envelopes of supply and return.

Since each space has a unique layout and function, CFD analyses can help to optimize the design of aerodynamic containment.

##########

Based in Ann Arbor MI, the author is an ASHRAE Fellow and President of AnSight LLC, his own consulting engineering practice specializing in computational fluid design (CFD) for building HVAC and data centers. Contact: [email protected].