Protecting Workers in Post-Anesthesia Care Units

By Kishor Khankari, PhD, Fellow ASHRAE, AnSight LLC

Postoperative patients in the Post Anesthesia Care Unit (PACU) of any modern hospital are the sources of waste anesthetic gases (WAGs). So healthcare workers in any PACU can potentially be exposed to hazardous WAGs.

To protect these workers, it’s important to design a ventilation system that effectively removes these gases and reduces exposure.

But the traditional approach of dilution ventilation does not account for the impact of airflow patterns and the resulting flow path of contaminants. By improving airflow patterns and optimizing the flow path of contaminants, the concentration of WAGs in the breathing zone of occupants can be reduced.

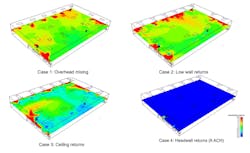

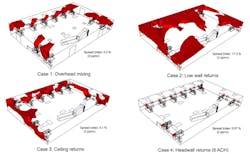

To optimize the performance of a PACU ventilation system, a computational fluid dynamics (CFD) study was conducted to evaluate the impact of various hospital HVAC layouts on the flow path of contaminants. The study employed a Spread Index metric to compare the spread of sevoflurane (a commonly used anesthetic gas) in the HVAC system of a typical PACU.

Contaminant Flow Path Matters

The traditional approach to ventilation design involves specifying a single number for the dilution air flow rate, often in terms of air change rates. This approach assumes that clean air will instantly mix with and dilute indoor contaminants concentrations to create a uniformly mixed, homogeneous air volume.

However, in reality, well-mixed indoor conditions rarely occur and are almost impossible to attain. The predominant location where a well-mixed concentration of contaminants can be observed is at the return grille or in the return duct.

In real-world situations, the contaminant concentration and the exposure of occupants can vary in time and space across all dimensions. Many factors relating to the design and operation of a ventilation system can impact such three-dimensional non-uniformity. These factors include the number, location, and type of supply diffusers; the volume of supply airflow or air changes per hour (ACH) and the throw of the diffusers; the temperature of the supply air; the number, size, and positions of return/exhaust grilles; the location and strength of various heat sources; the placement of furniture and other obstructions to airflow; and the layout of patient beds in the PACU.

Conducting physical tests for all these parameters under controlled conditions for various operating scenarios is time-consuming and labor-intensive, if not impossible. But CFD analysis offers a practical alternative for systematically evaluating these parameters. CFD can help to identify an optimal path for removing contaminants and ensuring a clean and safe environment for occupants.

Location of Return is Important

This study showed that the traditional HVAC layout with four-way supply diffusers and ceiling returns create mixing airflow patterns. These patterns can potentially distribute WAGs throughout the entire PACU, increasing the risk of exposure for healthcare workers.

Similarly, the low wall and ceiling returns layouts with ceiling laminar diffusers also create recirculating airflow patterns, which can bring sevoflurane (WAGs) plumes from the patient’s face into the breathing zone of attending healthcare workers. In the CFD analyses, the HVAC layout with laminar diffusers and headwall returns showed the most promise in reducing the concentration of WAGs in the breathing zone.

This layout promotes horizontal movement of a sevoflurane plume below the breathing zone of occupants combined with immediate exit of the contaminated air through the headwall returns. This significantly reduces the concentration of sevoflurane in the breathing zone and limits the spread of WAGs in the PACU.

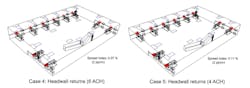

Opportunities for Energy Conservation

The study also indicates that the PACU with such an optimized HVAC layout can be operated at reduced dilution airflow rates without significantly affecting ventilation performance. This confirms that it’s not the air change rates but the airflow patterns that play a crucial role in the effective removal of contaminants.

By using CFD to analyze and optimize airflow patterns in indoor spaces, it’s possible to limit the spread of contaminants and reduce the exposure of occupants. Such optimized ventilation designs can further reduce energy consumption, first costs, and the operating costs of the HVAC system.

####

The author is founder of AnSight LLC, based in Ann Arbor MI. As a specialist in Computational Fluid Dynamics (CFD), Dr. Khankari's passion for solving engineering problems and providing sound scientific solutions has led to innovations and optimized designs in the industry. A noted expert in his field, he has a Ph.D. from the University of Minnesota and has published in several technical journals and trade magazines. An ASHRAE Distinguished Lecturer, he makes regular presentations in various technical conferences and professional meetings worldwide.