Fighting Air, Surface Quality Hazards with Air Disinfection Biosecurity Technology

By TRAVIS JONES, Vice President and General Manager, Lighting, Wesco International

While airborne diseases are not a new problem, the COVID-19 pandemic exacerbated the critical importance of indoor air quality (IAQ) to our health and is driving increased interest in technologies purpose-built to combat air and surface hazards, including non-line-of-sight.

While Ultraviolet (UV-C) is often considered the de facto solution to effective quality control, Air Disinfection Biosecurity (ADB) solutions are growing in adoption. With an arsenal of successful use cases and scientific proof of effectiveness, more and more organizations are beginning to recognize the indisputable benefits of ADB in continuously improving IAQ while fighting the spread of COVID-19 and other airborne pathogens and potentially neutralizing certain volatile organic compounds (VOCs).

While Powerful, UV-C Also Has Challenges

For more than 40 years, UV-C has been used to disinfect drinking water, wastewater, air and surfaces but it also presents several challenges.

UV-C unoccupied space solutions, typically portable units brought into a space for a certain period of time, cannot be used when people are in the room and are limited by line of sight. Surfaces between the UV-C source and target area block UV-C disinfection, therefore all surfaces may not be adequately disinfected. In addition, after the unit is turned off and people come back into the room, someone with COVID-19 or another infection may contaminate the space. Disinfection can’t take place until the next time the UV-C solution is used.

UV-C solutions, such as upper air and in-duct systems, can be used for occupied spaces, but they may not adequately clean surfaces and also have the line-of-sight disadvantage. In addition, upper air UV-C systems, only disinfect air and not surfaces. They rely on convection currents to circulate air past the UV-C source and must be installed at a certain ceiling height to ensure proper air flow. Direct view UV-C systems require exposure time be limited. These systems require a lot of time for disinfection and also have a short lamp life that may require changing every 41 days. In-duct UV-C solutions, like upper air UV-C systems, cannot be used to disinfect surfaces.

A main disadvantage of UV-C solutions is that they may take hours to completely eliminate airborne pathogens in occupied spaces. While UV-C has been a mainstay in the industry, the associated challenges are encouraging organizations to seek alternatives to ensure a safe working environment in a post-pandemic world.

ADB Offers Natural Pathogen Elimination

ADB is a scientifically validated antiviral and antimicrobial technology that uses ambient air as a vehicle to continuously mitigate pathogenic and other impurities in the air and surfaces (including non-line of sight) safely, effectively and efficiently. It can be used in both occupied and unoccupied spaces to continuously inactivate and neutralize viruses, pathogenic bacteria, mold, fungus, mildew and potentially certain VOCs through an advanced surface and air sanitation process.

In fact, ADB technology was initially deployed across the meat processing industry in Chile to kill e-coli and salmonella. Based on the success in the meat packing market, it was realized that ADB would be effective in indoor air spaces as well. In 2021, a U.S. company was selected to introduce it to the markets outside of meat packing and produce segments. Therefore, it is now starting to gain traction in the United States as more and more organizations understand the value of ADB in efficiently and effectively improving IAQ while combating airborne diseases.

Compared with the combination of UV-C and manual cleaning, ADB technology uses no replenishable product, requires little manual intervention and typically a shorter time for disinfection. Research has shown that ADB removes the COVID-19 virus from surfaces in 15 minutes and in the air in one minute, allowing facilities to reduce the danger of “close contact” as defined by the CDC as “within six feet for a total of 15 minutes or more.”

How ADB Works

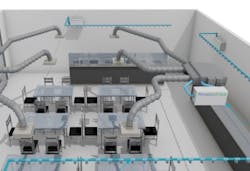

ADB technology is integrated into existing HVAC/air handling systems or used as a stand-alone unit for individual rooms. Ambient air is captured and exposed to high-frequency controlled electrical pulses within the ADB system’s chamber. Moisture from the air is broken down at the molecular level without employing any toxic chemicals. This creates a burst of charged particles referred to as Highly Reactive Molecules (HRM), including gas-phase hydrogen peroxide (H2O2)—a powerful biocide, superoxide, and singlet oxygen.

These byproduct particles (primarily H2O2) are then dispersed through the air via the HVAC/air handling system or portable unit, acting as airborne neutralizing agents. Charged particles contact air and surface pathogens, destroying their DNA/RNA to render them inactive. All surfaces are exposed to treated air, which neutralizes most common disease-causing microorganisms. The molecules that don’t react with a microbe simply revert to oxygen, leaving zero residues or chemical by-products.

Applications for ADB Technology

K-12 schools are some of the first looking to implement ADB technology as a continuous cleaning solution to address indoor air quality, including airborne pathogens such as COVID-19. While schools have put in place aggressive surface disinfection using sanitizers or bleach to treat harmful pathogens, they are one-time treatments that don’t address airborne pathogens.

Indoor air quality as a whole is also a concern.

In June 2020, the US Government Accountability Office released a report that found about half of the nation’s K-12 public schools needed to update or replace multiple systems such as HVAC or plumbing. According to the GAO report, if not addressed, problems with their HVAC systems can lead to indoor air quality problems and mold, and in some cases cause schools to adjust schedules temporarily.

ADB’s ability to continuously fight airborne pathogens and improve air quality can increase the attendance, comfort and performance of students, teachers, and staff and reduce the potential for school closings or the relocation of occupants. As a mobile option in buses with external HVAC units, ADB can be used to prevent cross- contamination on buses used for multiple grades on a staggered schedule, helping to keep both students and drivers healthy.

As expected, healthcare facilities are also deploying ADB to fight COVID-19.

For example, in September 2021, a primary care clinic in North Carolina announced that it had deployed ADB units in its duct work in high-risk areas of the facility. According to the practice, it had installed two test ADB units near it’s dedicated COVID exam rooms and an independent laboratory had monitored the clinic’s bio-load, using bio-markers of a similar size to the human exhaust that contains the coronavirus. Results found that ADB had reduced the airborne bio-load by 80 and 86 percent in two different zones, and surface bio-load in these two zones was reduced by 87 and 91 percent.

ADB can also reinforce safety in common areas without impacting staffing or traffic flow, making it applicable for meeting rooms, break rooms, locker rooms, work areas, cafeteria/food preparation and business public areas.

Is ADB in your future?

Although it’s relatively new to the U.S. market, ADB technology is scientifically validated by over 100 independent tests and studies show its safety for use in occupied spaces. For over 25 years, ADB has been deployed in over 20,000 worldwide installations that protect more than 900 million cubic feet of indoor air.

Today, while there may be more types of UV-C solutions vying for market share, ADB has the potential to surpass UV-C and other air disinfection solutions because it’s proven to be an extremely effective, stand-alone solution for continuous airborne and surface pathogen mitigation in occupied and unoccupied spaces.

In a post-pandemic world, air and surface quality control is not a nice-to-have, but is essential in helping organizations combat the spread of disease, protect employees, and ensure a safe working environment. While traditional solutions such as UV-C and others have worked in the past, the proven effectiveness of ADB cannot be denied and should be carefully considered as organizations evaluate their options to mitigate the risk of disease, safeguard employees from harm, and keep life running smoothly.

Based in Austin TX, the author is Vice President & General Manager of Lighting at WESCO Distribution, a multinational electrical distribution and services company based in Pittsburgh PA.