Coalescing Air Separator Removes Entrapped, Entrained, Dissolved Air

Utilizing a conventional air separator that removed entrained air — air traveling in a water stream in bubbles that can be seen with the human eye — but not entrapped air — air that has migrated out of a water stream and into high points as pockets of air — or dissolved air — microscopic bubbles that coat heat exchangers as the velocity of water through coils is reduced — Youngstown State University (YSU) in Youngstown, Ohio, made the commitment to test and document the performance of a coalescing air separator, which manufacturer Spirotherm claimed could rid a hydronic system of up to 99.6 percent of all air.

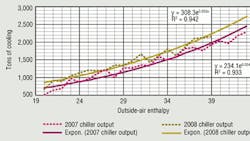

YSU decided to test the campus chilled-water loop. In 2008, a 20-in. coalescing separator rated for total plant pump capacity was installed. Figure 1 compares pre- and post-installation data.

Total out-to-campus tonnage averaged 15.9-percent more than YSU was able to attain with the previous air separator under the same operating parameters. That was a direct result of chilled-water coils now being able to absorb heat in the absence of system air.

On summer design days in 2007, YSU had observed buildings with the longest equivalent pipe length from the central plant struggling to come within 5°F of discharge-air-temperature (DAT) set points. As a result of the higher tonnage output to campus, coils now were able to met their design intent, and two-way valves were beginning to close when previously they still would have been stroked open. That allowed chilled-water flow to the most remote areas of campus.

Another benefit of the air removal and higher delta-T on the chilled-water supply and return was chiller-efficiency gain. New electric centrifugal chillers were optimized for a 10°F delta. With the chillers operating under design conditions, YSU was able to achieve the maximum efficiency attainable by the equipment. Further efficiency gains will be recognized as YSU addresses flow constraints dictated by the buildings on campus. As the chilled-water system's efficiency gains translate to energy savings at the chillers, additional savings will be gained when YSU is able to take advantage of variable primary pumping.

Measures to reduce energy use further include campuswide air-side coil cleaning and revised preventive-maintenance schedules. Once the chilled-water system is optimized, YSU plans to implement the same energy-efficiency measures for heating systems.

Information and photograph courtesy of Youngstown State University.

Circle 101