Cornell Upgrades Water Piping Infrastructure

By John Williamson, PE, PACP, Director, and Stephen Pollard, PE, Project Manager, RMF Engineering

Located in Ithaca, NY, Cornell University is a private, Ivy League, land-grant research university founded in 1865. The 2,300-acre central campus is a well-developed suburban college landscape, comprising academic, dormitory, laboratory, library, athletic and service buildings.

To ensure the safe and reliable access to drinking water and fire water service on campus for decades to come, the University replaced existing 8- and 12-inch water mains that spanned approximately 1,800 feet long, including the replacement of laterals to buildings and fire hydrants. RMF Engineering partnered with the University to conduct studies and prepare designs to facilitate the $1.4 million project’s success in construction, which was completed in 2022.

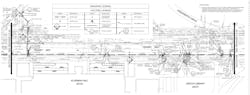

The project site extended from Tower Road at the south to University Avenue at the north, with existing utilities within the area, including domestic water, sanitary sewer, storm drainage, medium-voltage electric, site lighting, telecommunications, natural gas, steam and condensate, chilled water, condenser water, and irrigation. The bulk of the project took place along Feeney Way, a south to north roadway located in the central portion of campus, with one lane for vehicle traffic in each direction as well as bicycle lanes, bus pull-offs, crosswalks, and setback pedestrian sidewalks.

Cornell took advantage of the required traffic disruption along Feeney Way to perform full-depth replacement of approximately 500 linear feet of the roadway’s asphalt surface. RMF also played a large role in facilitating these upgrades, including the replacement of a concrete steam manhole and regrading the pedestrian ramps to meet ADA standards.

Water Main Replacement

A hydraulic analysis was performed on the existing campus domestic water system model to determine the pipe size requirements for the replacement main and evaluate available material options. RMF utilized Cornell’s Bentley WaterCAD domestic water hydraulic model, amending it with the proposed piping and comparing the results with the existing configuration, determining that a 12-inch DR11 HDPE main (inside diameter 10.65 inches) would be sufficient for the existing building loads.

To evaluate the most effective utility route, the team performed a topographic survey capturing all vehicular lanes, pedestrian walkways and islands, planimetric features, utility structures inverts and grades. Additionally, a preliminary field observation was used to confirm the location of existing valves, adjacent utilities, and site features.

The proposed alignment was close to the west side of Feeney Way in a clear corridor, which had the added benefit of preserving most of the roadway to maintain vehicle traffic during construction. Branch connections to fire hydrants and building services extended perpendicular across the roadway, and piping was routed to allow for complete installation and testing prior to connection to existing services.

The existing 8-inch domestic water main was located in the southbound lane, while the existing 12-inch domestic water main was placed near the roadway centerline. Due to its age, the existing 8-inch water main was unrestrained, relying on soil to resist hydraulic forces.

Branches to buildings and fire hydrants extended from either the 8-inch or 12-inch main. However, not all building loads were supported by both. Other utilities running along and/or parallel to Feeney Way included electric and communications ductbanks along the west sidewalk, and a gas main along the east curb line.

Also of note, the existing water main ran in close proximity to the proposed 12-inch water main; the sequence of construction de-energized the existing 8-inch water main during excavation and installation of the nearby 12-inch water main, identifying service outages. The 12-inch domestic water main is DR11 HDPE, outfitted with butt-fused joints and 12-inch iron-bodied mechanical-joint gate valves.

The minimum cover over the HDPE domestic water line is 54-inches, and domestic water valves are AWWA C515 resilient wedge gate valves. The fire hydrants are AWWA C502, UL Listed, FM Approved, NSF 61 with a certified dry barrel design and breakaway flange with a 5-1/4-inch operating valve, two 2-1/2-inch hose outlets, and a single 4-1/2-inch pumper connection.

One of the more challenging areas of the water main installation was located at the northern connection, right at the Feeney Way and University Avenue intersection.

The intersection is heavily used not only by passenger cars, but also by campus buses and other large vehicles, including construction equipment for other ongoing campus projects. Even though Feeney Way was closed at this point in the construction, maintaining flow through the rest of the intersection added another element to manage with the excavation and water main connection process.

The water piping infrastructure upgrade was completed during the summer of 2022. To meet the phased water main installation approach, the southbound lane was closed in portions, using steel plates during non-construction hours to provide two-way traffic along Feeney Way. The road was closed to vehicle traffic for a 4-week period during the summer construction period for the full-depth road replacement.

Taking advantage of this road closure, the water laterals to building connections and fire hydrants were made. Due to the academic schedule, the team had to work diligently within this tight timeframe to successfully evaluate the issues and implement solutions ahead of the approaching fall semester.

Construction Phasing and Sequencing

Coordination with campus services was key when it came to scheduling outages—particularly for facilities that aligned when they were inaccessible due to construction activity. In order to understand the outages that connecting the new system to existing services would entail, the team had to carefully consider the existing system valves to use them to minimize outages for new to existing connections.

The team installed, tested, buried and cleaned the new piping in its entirety prior to making final connections to the existing 12-inch main at Tower Road and University Avenue. Once the new water main was in service, utilizing newly installed, strategically placed isolation valves, the connections to the existing building water branches were completed with coordinated outages, minimally impacting the water service to the buildings.

Vehicle and pedestrian traffic control and phasing plans were thoughtfully developed to maintain sequences of construction and restrictions that maintain access needed by emergency vehicles, campus services, and pedestrians (students, faculty, and the general public). The dual, parallel sidewalks and crosswalks spanning Feeney Way easily enabled pedestrian detours around the work area. Additionally, the two bus stops and service vehicle parking areas were an important campus operations factor to consider.

Pavement Improvements

In addition to the water main design, RMF prepared designs for the full-depth roadway replacement in plan, section and profile. The team also provided the structural design for the replacement of the walls and top of a concrete steam manhole.

The Feeney Way Tower Road intersection is a heavily trafficked area of the campus, leading to mis-matched curb ramps and crosswalks that were showing signs of deterioration accelerated by saturated base materials, leading to the full replacement of the asphalt pavement and subbase, spanning approximately 400 feet.

Damaged granite curb was replaced, and pedestrian crossings were upgraded to the current Cornell standard with detectable warning surfaces and heavy duty asphalt pavement. In addition, a perforated underdrain was added to the east gutter line to capture infiltrating water and remove it from the pavement section to avoid the same issue in the future.

Roadway improvements also included an existing northbound bus stop at Rockefeller Hall, which was constructed of asphalt and had become rutted from use, and the concrete southbound bus stop at Lincoln Hall, which became cracked—both of which presented tripping hazards to pedestrians. The bus stops were fully replaced with Cornell’s standard concrete bus stop, which uses a 9-inch thick concrete slab and 12-inch thick subbase with underdrain. Again, taking advantage of the 4-week full road closure, the replacement of the bus stops was complete without impacting traffic flow and additional bus services.

Conclusion

Taking advantage of infrastructure upgrades to support overall campus functions, Cornell University’s partnership with RMF Engineering resulted not only in the necessary water main replacements, but the aesthetic and functional upgrade of various roadway elements, including manholes, bus stops, and crosswalks. Strategically utilizing a phased approach to construction, the project minimized disruption to the campus and surrounding traffic while creating infrastructure needed to support its operations for years to come.

#####