Four Pillars of a Healthy Hot Water System

By BRIAN ARMSTRONG, Director, Hot Water Group, Armstrong International

Designing a best-in-class hot water system that meets a building’s hot water requirements while ensuring the health and safety of its occupants is not a simple task.

Engineers are faced with the potential threat of waterborne pathogens like Legionella, the risk associated with extreme water temperatures, and the need to maintain organizational and regulatory compliance.

While there’s no one-size-fits-all solution to achieve a healthy hot water system, engineers can build in lasting safeguards and efficiencies by focusing on core design and operational principles, emphasizing four key pillars: infection control, scald protection, compliance and sustainability.

In some organizations, these priorities may also be governed by the requirements of a Water Management Plan (WMP)—a facility-specific strategy typically overseen by the facility manager or safety team, with input from consultants and engineers, and guided by standards such as ASHRAE 188-2021 and Guideline 12-2020.

Ultimately, when system design reflects these four key pillars, and aligns with an established WMP where applicable, engineers help ensure hot water delivery that is safe, reliable and efficient. Let’s take a closer look at each pillar.

Infection Control

Waterborne pathogens, especially Legionella, require a thoughtful risk management strategy. But because water quality and system design vary widely across the U.S., and because Legionella can thrive under many environmental conditions, there’s no universal solution. Instead, specialists use the concept of barriers: combinations of processes, tools, and procedures that help control the spread of infection.

The most essential barrier is water temperature. All parts of the hot water infrastructure should be maintained above the Legionella growth range high limit of 122°F (50°C), and initially heated to or periodically elevated to 140°F (60°C) or above, which kills the bacteria within 32 minutes.

The age of the water also matters. Areas such as pipe runs leading to low-use fixtures can allow water to stagnate and drop into the 95°F–115°F (35°C–46°C) range, which is ideal for Legionella growth. To mitigate this, engineers can reduce those distances using appropriate piping technologies, fittings and design recommendations. Likewise, periodic fixture flushing is an additional infection control measure.

Mineral Deposition and Biofilm

A discussion about infection control isn’t complete without addressing biofilm, the organic slime that builds up inside hot water systems. Left unchecked, it provides a nutrient-rich environment for bacteria.

A 2024 study by the Montana State University Biofilm Engineering Department found that scale buildup in pipes provides a scaffold for biofilm. ASPE affirmed this in its 2022 publication Engineering Methodologies to Reduce the Risk of Legionella in Premise Plumbing Systems, noting that scale contributes to flow restriction, water heater inefficiencies and pathogen development.

Historically, removing scale required ongoing maintenance. Today, nanobubble technology offers a chemical-free, automated solution. Installed as a static side-stream, the system creates microscopic bubbles that remove scale and prevent future deposits. This improves system hygiene and performance without introducing additives, making it ideal for both new builds and retrofits.

Scald Protection

Scald prevention is another important pillar of a healthy hot water system, and developing a methodology for optimizing against scald risk cannot be ignored—both for the safety of the users and the operators.

Today’s digital mixing valves maintain a high degree of set point accuracy. They provide precise temperature control, resist temperature creep, and can communicate with building automation systems to enhance user safety. These valves typically hold temperatures within 2° of the setpoint and can issue alerts or default to cold water/return water only, as needed.

Temperature creep—a gradual increase in system temperature during zero fixture demand—can result when return water isn’t properly proportioned. High-performance digital mixing valves offer multiple integral thermistors to help reduce this risk.

In high-temperature systems, those calling for 140°F/60°C or above, point-of-use protection becomes even more important. Thermostatic shower valves and under-sink thermostatic mixing valves (TMV) offer basic scald protection, but their performance depends heavily on proper setting and maintenance. The most protective feature is the hot stop, which limits maximum temperature, but it requires seasonal adjustment and must be reset after servicing. A misadjusted hot stop can expose users to scalding temperatures.

For simplified protection, a lower-temperature recirculating hot water system with a digital mixing valve set point of 123°F/51°C – 125°F/52°C, served by a >140°F/60°C water heater, can reduce the need for thermostatic point-of-use temperature control. In these systems, pressure balance shower valves (PBV) offer added protection by compensating for supply pressure changes and shutting off flow entirely during pressure failure.

At lavatories, the scald risk is lower since users can typically withdraw hands quickly. While special consideration may be needed for infants, the elderly, and individuals with physical limitations, for general use, a mechanical valve with an integral hot stop set to 110°F (43°C)—installed ahead of the faucet and supplied by 122–125°F (50–52°C) water from a digitally controlled recirculating system—offers a simple and effective solution.

Digital Water Temperature Control

Modern technologies make it easier to maintain infection control barriers, especially temperature-based strategies that inhibit Legionella growth. For example, digital recirculation valves, whether installed at the point of source or zoned throughout the building, can keep system water within 2° of the setpoint. High-performance models with a 1° inlet-to-outlet differential are particularly effective. This precision allows systems to maintain minimum temperatures without setting the mixing valve at a dangerously high outlet temperature.

Primary or secondary hot water temperature control at the point of use has been an accepted practice but plumbing designs that specify point-of-use TMVs bring challenges. TMVs often contain rubber seals and narrow passages, which can foster bacterial growth. By design, they also restrict high-temperature disinfection unless manually overridden and reset, adding to the maintenance load.

It is also important to operate the circulation pumps continuously. Thermostatic and digital master mixing valves, which require an aquastat to shut the pump off for over temperature protection, may compound the risk of pathogen growth in stagnant, warm water. Codes and regulations that require pumps to shut off as an energy-saving measure should be challenged accordingly.

Compliance

A healthy hot water system must also align with the applicable Standards of Care, including:

- OSHA Technical Manual;

- Joint Commission Environment of Care;

- ASHRAE 188-2021;

- ASHRAE Guideline 12-2020;

- VA Directive 1061

These documents offer guidance on water temperature control limits, monitoring, documentation and response protocols. A properly implemented WMP, as discussed earlier, plays a key role in meeting these standards.

Compliance is especially critical in healthcare. In 2017, the U.S. Centers for Medicare & Medicaid Services (CMS) issued a directive requiring hospitals and long-term care facilities to implement policies that reduce microbial growth in building waster systems. Since CMS controls Medicare and Medicaid reimbursement, loss of certification can have serious financial consequences. This can be done either by a state inspection, or the hospital can opt to pay to be certified by Joint Commission (a CMS certification subcontractor).

The CMS directive (which used ASHRAE 188 as a guideline) marked the most significant change in how facilities were required to manage and prevent the spread of Legionella since the bacteria was identified following the 1976 Legionnaires convention in Philadelphia.

Finally, all products used in a hot water system must be certified and comply with the relevant standards for hot water systems by the International Association of Plumbing & Mechanical Officials (IAPMO) and the American Society of Sanitary Engineering (ASSE).

Sustainability

The way we heat water is changing. Many states and cities are adopting electrification policies to reduce dependence on fossil fuels. CO₂-based air source heat pumps are being heavily promoted for commercial applications, thanks to their strong efficiency performance, low environmental impact, and suitability for domestic single-pass water heating.

However, they are not well-suited for recirculating hot water systems. These systems require multiple tanks, including swing tanks, that often hold water in a temperature range that promotes Legionella growth, making them incompatible with ASHRAE 188 and Guideline 12.

New, high-temperature water-source heat pumps, on the other hand, are a strong option for buildings that can recover waste heat from chillers, exhaust fans or sewer systems. Still, energy efficiency improvements can be made without switching to electric. An ongoing study with Pacific Gas & Electric examined a simulated 44-unit apartment environment at their San Ramon, CA, test lab. The study has shown that using point-of-source water temperature control (central master mixing valve) yields energy savings between 10% and 18% when compared with point-of-use controls.

This was attributed to reduced system heat loss at higher recirculation temperatures, along with reduced tank stratification. These findings were further validated in real-world installations of digital mixing valves at hotels and medical facilities, and they will be used as evidence to propose plumbing code changes in California.

Condensing water heaters, while not new, have become highly efficient in recent years, generating 99 cents worth of hot water for every dollar spent on fuel. While the goal is to eliminate fossil-fuel use eventually, the abundance of low-cost, relatively clean-burning natural gas in North America makes it a compelling option. Until we move completely away from fossil fuels, a logical interim solution would be to adopt a hybrid system that uses a water-source heat pump for baseline load and a gas-fired heater for peak demand—ensuring a reduction in fuel use while maintaining performance.

On-demand water heaters are another efficient option. These systems avoid standby heat loss, deliver up to 99.8% operating efficiency, and can heat water to disinfection temperature before blending it down with onboard digital controls for recirculation.

Finally, as we’ve already discussed, nanobubble technology also supports sustainability by removing scale, improving heat transfer, and reducing the energy required to heat or cool water.

A Holistic System Approach

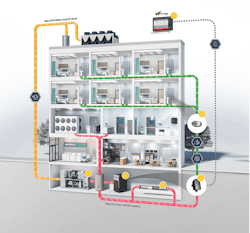

Each hot water system has a unique profile, shaped by variables like building type, usage patterns, fixture layout, geographic location, seasonal water temperature shifts, and water chemistry.

But regardless of those differences, the foundation for a healthy system must prioritize infection control, scald protection, compliance, and sustainability. By anchoring to these four pillars, and implementing a thoughtful WMP, engineers can deliver systems that are safer, more efficient, and better equipped to meet the demands of today’s buildings.

In doing so, this will not only protect users and operators in the present but also build resilient infrastructure that stands the test of time.

#####