Utilizing Plant Effluent for Heating and Cooling

DeKalb County, Ga., is expanding its Snapfinger Creek and Pole Bridge Creek wastewater-treatment plants. The Snapfinger facility's capacity will increase from 36 to 54 mgd, while the Pole Bridge facility's capacity will increase from 20 to 39 mgd. The total cost of this expansion project, including a 5-mile tunnel used to transfer sewage and/or treated effluent between the plants, is estimated to be more than $900 million. The expansion will comprise a laboratory; headworks structures, including screens and grit-removal machinery; influent lift-station improvements; dewatering, administration, and membrane-filtration buildings; maintenance structures; and various other support facilities.

Developing Goals

The design team was chartered by DeKalb County to develop the most cost-effective and sustainable improvements possible for the plants. As part of this green effort, the design team developed a concept that would utilize the plant effluent for heating and cooling.

The HVAC system needed to address several areas, including:

- Lowest possible first and operating costs.

- Flexible operating conditions.

- Humidity issues for the laboratory building.

- Occupant-comfort levels.

- Obtaining maximum points in the Energy and Atmosphere, Indoor Environmental Quality, and Innovation in Design LEED categories.

Reusing Water

The plants’ effluent typically stays between 55˚F and 78˚F year-round, providing an excellent heat source and heat sink. A water-source heat pump typically uses potable water as a heat source and heat sink for situations in which split-system condensers cannot be located outdoors easily or cost-effectively. However, using potable water in this manner generally is not cost-effective because of its relatively high cost.

Several years ago, the county initiated a master plan to make reuse water available throughout the DeKalb community. To generate the cleanest water possible economically, the wastewater-facility project instituted a membrane-bioreactors process, which uses synthetic membranes to filter water prior to discharge. The membranes have a pore size of less than 0.04 micron, resulting in effluent that is equivalent to potable water. The end product is a virtually unlimited supply of very clean effluent—near drinking-water quality.

The design team initially studied water reuse to cool and heat the Pole Bridge Creek facility's laboratory building. When this seemed feasible, the design team wanted to utilize the process for all of the buildings at both plants, a total of more than 20 structures. Applications included offices, electrical rooms, and maintenance areas. Using the plants' effluent water eliminated the need for a cooling tower or boiler, as well as the associated chemical-treatment equipment and pumps, creating a first-cost savings of approximately $120,000.

Solving Challenges

One of the most challenging issues was identifying a water-source heat pump that could handle the cooling and heating loads demanded by laboratory fume hoods. The largest laboratory area had six fume hoods with a total makeup airflow of 5,500 cfm, utilizing 100-percent outside air. The water-source heat pump had to be able to handle the large latent load, vary the airflow based on the number of fume hoods in operation, and maintain a comfortable room temperature for laboratory personnel.

A packaged rooftop water-source heat pump was able to accommodate all of the laboratory's operating conditions. The pump has a variable-frequency-drive option that can vary airflow based on the number of fume hoods in operation, as well as hot-gas reheat and bypass to control condensing pressures, avoiding evaporator freeze and controlling discharge-air temperature.

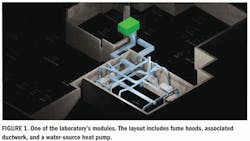

Each of the laboratory's four modules was designed for a specific function, such as wet chemistry, biological testing, field services, or general chemistry. Figure 1 illustrates the modules' layout, which includes fume hoods, the associated ductwork, and a water-source heat pump.

The laboratory also includes office areas, conference and training rooms, shower and bath areas, an instrumentation room, a lounge, and lobby areas. Each area was conditioned with a separate packaged rooftop water-source heat pump.

Reducing Costs

Because the effluent temperature remains between 55˚F and 78˚F, it was not necessary to install a cooling tower to reduce water temperature or a boiler to increase water temperature in the laboratory. Comparisons of traditional HVAC systems with a water-source heat-pump system using effluent for the laboratory showed:

- Air-cooled chillers and air handlers with electric heat cost approximately $90,400 in energy per year.

- Air-cooled chillers and air handlers with gas heat cost approximately $75,400 in energy per year.

- Water-source heat pumps and plant effluent cost approximately $34,000 in energy per year.

This data shows a water-source-heat-pump system was able to decrease energy costs for the laboratory, which has a cooling-system capacity of 100 tons and a heating-system capacity of 1.51 MBtuh.

Both plants' administration buildings use above-the-ceiling horizontal water-source heat pumps to provide cooling and heating. Their electrical rooms are served by platform-mounted water-source heat pumps with horizontal supply and return ductwork (Figure 2). The administration buildings' HVAC-system energy-usage rates are approximately 0.45 kw per ton, compared with traditional HVAC-system energy usage of approximately 1.2 kw per ton, a savings of 60 percent.

The total cooling load for both plants' electrical rooms and office areas—excluding the laboratory—is 475 tons. With a traditional direct-expansion cooling system, energy costs for these areas would amount to $120,000 per year. However, the energy costs of the water-source-heat-pump cooling system using plant effluent water as a heat sink amount to only $46,000 per year, a 60-percent savings.

Overall, selecting water-source heat pumps and using plant effluent will save DeKalb County more than $2 million in capital costs and approximately $150,000 per year in power.

Did you find this article useful? Send comments and suggestions to Associate Editor Megan Spencer at mailto:[email protected].

A senior mechanical engineer for S.L. King & Associates, Lawrence Perry has 20 years of experience designing HVAC, process, and plumbing systems for institutional, industrial, and commercial facilities, including load calculating, duct sizing and routing, equipment selection, specification preparation, code compliance, and energy analysis. He has a bachelor’s degree in mechanical engineering from South Carolina State College.