Biomass District Energy Provides Economic, Environmental Benefits

When John Cressy became facilities director for Sullivan County, N.H., six years ago, a study of the feasibility of utilizing biomass to reduce reliance on foreign fossil fuels and reduce carbon emissions was under way. The study did not meet the county’s expectations, and the entire project was shelved. Then, the Wood Education and Resource Center stepped in and offered to do a new feasibility study.

“The study blew our minds,” Cressy said. “The numbers looked almost too good to be true.”

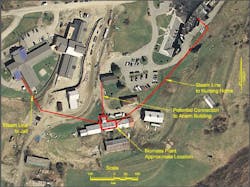

The county decided to move forward with a biomass heating system for a new 3,000-sq-ft building, part of a nursing-home, office, and prison complex in Unity, N.H.

After much research by Cressy and his team, the county purchased a Hurst biomass-boiler district heating system with back-pressure steam turbine/generator to provide space heating, hot-water heating, power for steam dryers, and power for a kitchen.

“Ninety percent of our fuel load has replaced fossil fuels,” Cressy said.

Bob Waller and his company, Scarborough, Maine-based Thermal Systems Inc., oversaw the specification, procurement, and arrangement of the equipment.

“Even though it’s still a new system, I’m very pleased with the Hurst equipment,” Cressy said. “It’s robust, which is important in New Hampshire, as we put heating systems through a lot up here.”

Hurst equipment utilized on the project included:

- A 5.0-MMBtuh, 150-psi hybrid biomass boiler.

- A fuel-reclamation system custom-engineered to encompass a nine-tree reciprocating floor. This was a complex challenge requiring specialized construction designed to take into account the unique natural terrain of the site and the 15-ft elevation discrepancy between the material-handling and storage areas of the boiler room.

- An Oxymiser deaerator with duplex pump set.

- An 80-hp, 150-psi propane package boiler.

The $3.4 million project was funded through a tax-exempt bond through a local bank, as well as several grants totaling $675,000, including:

- A North Country Resource Conservation & Development grant worth more than $75,000.

- A U.S. Forest Service Forest Products Laboratory grant worth more than $250,000.

- A New Hampshire Public Utilities Commission Commercial & Industrial Thermal or Electric Renewable Energy Project grant worth more than $300,000.

So far, the benefits of the biomass system have exceeded expectations. Over the system's first four months of operation, the county realized 20-percent fuel-cost savings. The county expects annual fuel savings to pay for the construction bond within 15 years. With the sale of energy credits, the county expects to receive a minimum of $75,000 of offsetting revenue per year. Additionally, the project allows all of those energy dollars to stay in the local economy.

Inspired by the success of the project, Cressy has been working on educational outreach regarding the benefits of biomass energy within the county.

“One of the most important parts of this biomass initiative is building public awareness of the benefits of lessening dependence on fossil and foreign fuels, thus, putting more dollars into the local economy,” Cressy said.

Cressy added that most of the wood chips used for fuel come from within a 5-mile radius of the county complex.