With surgical admissions accounting for nearly 50 percent of their revenue,1 the operating room is critical to the operation and bottom line of most hospitals.

Ensuring conditions in operating rooms are optimized is critical—not only for patient health and safety, but the comfort and efficiency of surgeons and medical staff. Furthermore, ensuring proper conditions in operating rooms is important for the performance of critical surgical equipment, which may require tight humidity control, and for infection control.

Quality HVAC systems that deliver consistent cooling and precise control are essential to operating-room conditions, with the need for dehumidification becoming a key design consideration.

Typically, operating rooms are controlled to a temperature of 60°F to 68°F with a dehumidification set point of 50 percent to 60 percent relative humidity (RH). Often, traditional HVAC equipment is unable to meet these dehumidification requirements, leaving rooms with humidity levels higher than those required. New, advanced technologies offering better performance, flexibility, and efficiency in meeting strict surgical ventilation, humidity, and temperature requirements are available, however.

A Challenging Situation

The benefits of dehumidification in operating-room applications—moisture removal can improve indoor-air quality and the comfort of doctors, staff, and patients and support equipment-performance and safety standards—are clear.

A hospital has many spaces with varying applications and demands. For drier air to be produced for one of those spaces, the temperature of the entire chiller plant must be low, or additional chillers may need to be installed. This can be costly, and it decreases the efficiency of entire systems.

A surgeon could set the thermostat in an operating room to a level lower than the system was designed for—setting it to 62°F when it is designed for 68°F, for example—with the desire to keep the room at 50 percent RH. The system may be able to cool the room to 62°F, but the air needs to be delivered drier. Instead of a sub-48°F dew-point temperature, the air now has to be dehumidified to a sub-42°F dew-point temperature to maintain 50 percent RH.

Adding cooling capacity may not even help in these situations, because it is an issue of the ability to reach the dew point. If the operating room needs a 42°F dew point and the system produces 42°F chilled water, the air cannot be dehumidified with traditional HVAC systems.

Advanced Technology Makes It Possible

After extensive research and development, new technologies allowing economical handling of cooling in high-temperature, high-humidity environments without the need to add chilling capacity have been introduced. These advanced technologies enable a lower dew point while offering greater efficiency and reduced energy consumption, compared with adding chillers.

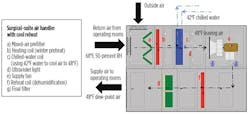

The advanced systems use a Type III isotherm desiccant wheel with a cooling coil, minimizing the need to reheat air to achieve proper humidity control and lowering the achievable dew-point temperature. An integrated active desiccant wheel captures water vapor from air leaving the cooling coil. The wheel then slowly rotates to be regenerated by return or mixed air upstream of the coil using no additional heat. As a result, operating rooms can stay at 62°F and 50 percent RH, even during hot summer months, without incurring any significant energy costs beyond what it would take to condition the room to 68°F and 50 percent RH with traditional cool-reheat systems.

Numerous Benefits for Hospital Operating Rooms

The technology offers numerous benefits, including improved cooling efficiency, because the chilled water or evaporator coil temperature can be kept 5 to 8 degrees warmer than systems without the technology. The ability to use warmer water saves hospitals on utility bills for the entire system.

Additionally, less cooling capacity is needed for operating rooms because air no longer needs to be cooled to the required dew-point temperature. The system helps to save on infrastructure costs because it reduces the amount of reheat needed, and there is no need to invest in additional chillers to make colder water.

In addition to energy savings and efficiency, the increased flexibility in performance provided by this technology helps hospitals meet the wide range of conditions surgeons may prefer for their operating-room environments.

Another benefit is the transition between patients in an operating room is much faster with this technology because the room can be cooled more quickly. This helps the hospital turn around the space between procedures more efficiently, which can help to increase revenue.

Lastly, because it always is treated by the wheel, air does not leave the air-handling system in a saturated condition, so there is less risk of wet filters and wet diffusers, which could cause an operating room to be closed temporarily.

Successful Results

At West Jefferson Medical Center in Marrero, La., this type of desiccant dehumidification system helps to attain the temperature and precise humidity control required for surgical suites and a robotic surgery system, removing up to 200 percent more moisture per hour.

In a traditional surgery suite, the advanced desiccant dehumidification system allows the hospital to maintain precise temperature and humidity control, despite the large quantity of extremely humid Louisiana outside air required in the suites to meet the most current codes for surgical-space conditions and air changes.

The desiccant system is part of a new air-handling unit (AHU) serving eight surgical suites. The dehumidification performance of the desiccant wheel allows the use of a much smaller cooling coil and significantly less reheat compared with a traditional chilled-water AHU with reheat. The cooling coils allowed for a smaller upfront investment and are expected to significantly lower operational costs over the life of the equipment.

In Louisiana, outdoor relative humidity, which seldom is less than 50 percent, can present a major HVAC challenge. The desiccant dehumidification solution is ideal for this type of application because it can meet the required lower dew-point settings and increase cooling-coil capacity by 20 to 300 percent.

Additional Considerations

Dehumidification requirements should factor into design specifications for equipment and determinations of how the equipment is controlled. On remodeling projects, these advanced systems do require changeout of the AHU, which provides the ability to utilize the same chilled water and achieve lower humidity.

To maximize results, choose an air handler with a low-leak casing, filtration options that meet room requirements, and thermal performance showing water will not condense on the exterior casing. Look for a unit that is certified by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI). Airflow measuring on the fan is another important feature to consider, as it helps to monitor how much air is going in and out.

These technologies can impact the performance and precision of systems for surgical environments. Air handlers available on the market provide numerous pre-engineered and tested options for moisture-removal needs, which can improve reliability and make installation easier.

For control of operating-room conditioning equipment, choose a manufacturer with a proven track record with the technology. Also, choose equipment capable of interfacing with the existing building automation system. This will help to optimize the performance and reliability of the equipment and system.

Conclusion

Insufficient dehumidification in a hospital operating room can negatively affect the performance of doctors and staff, the health and safety of patients, and the operation of surgical equipment. The challenge is to control humidity and temperature to the levels required in hospital operating rooms without driving up energy costs.

New advanced systems that offer crucial humidity control and energy efficiency, improving the dehumidification capacity of standard cooling equipment and enabling a much lower dew point, are now available. This technology helps hospitals keep their operating rooms at the necessary cool and dry conditions for the comfort of hospital staff and the safety of patients.

Reference

1) Weiss, A.J., Elixhauser, A., & Andrews, R.M. (2011). Characteristics of operating room procedures in u.s. hospitals, 2011. Rockville, MD: Agency for Healthcare Research and Quality. Retrieved from http://www.hcup-us.ahrq.gov/reports/statbriefs/sb170-Operating-Room-Procedures-United-States-2011.pdf

Ronnie Moffitt, PE, CEM, is senior principal applications engineer for Trane, provider of indoor comfort solutions and services and a brand of Ingersoll Rand. He has more than 20 years of experience in the HVAC industry, with a primary focus on dehumidification and air-to-air energy-recovery design in commercial buildings. He is an active member of ASHRAE and the Air-Conditioning, Heating, and Refrigeration Institute. He can be contacted at [email protected].

Did you find this article useful? Send comments and suggestions to Executive Editor Scott Arnold at [email protected].