Screen Cleaning: Best Not Overlook Those Seemingly Minor Details

By GEORGE GAMES, P.E., North East HVAC Engineering & Consulting, East Brunswick, NJ

Minor details have a way of getting under our skin at times. In some cases, especially in engineering, some "minor" details may not end up being so minor a concern, after all, when things are overlooked and later become problematic.

Let’s look at one type of engineering detail that may be easily overlooked, and that can create problems afterwards. Consider the location of mesh screens when used to protect inlet or exhaust air openings from things entering a duct system or a space inside a building or structure. As with any piece of equipment, the engineer should strive – must, really – to locate equipment so that maintenance personnel can get to it later, to replace, inspect and/or maintain it.

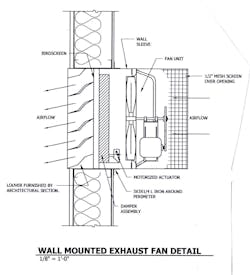

In this figure, we see an installation detail (that I came across in my review of a project’s drawing set) showing an exhaust fan installed in an exterior wall, a louver in the plane of the wall and a birdscreen and damper sandwiched between the louver and exhaust fan. I often come across details like this with screens mounted in such a way that they are inaccessible. It’s concerning.

If air was perfectly clean, this installation would be fine. However, we would all agree that air is dirty – hence the reason for using filters in many air systems, even those systems used in our homes. Even our cars nowadays have a cabin air filter to clean the air coming in through the vents.

With this installation in the drawing, how can the screen be accessed for cleaning? Certainly not from the inside. Not having access to it, it likely will be "left to its own devices” and neglected. There simply is no practical way of cleaning this screen unless you can reach it from the outside; if that’s even a possible.

The problem with this installation is that dirt will accumulate on the screen and increase airflow resistance, and the fan will not deliver the air it was expected to move.1 As the screen clogs up, airflow will decrease accordingly and degrade system performance.

In the accompanying photo, note how dirt sticks to an exhaust fan’s protective screen. This protective screen can be cleaned, even if the desire to do so may be questionable. However, a bird screen sandwiched between the louver and a damper and fan cannot be cleaned, unless access to it from the louver side is available. But even attempting to clean it through the louver is not practical as you may not reach all parts of the screen equally well.

In this case, an opening in the duct sleeve between the screen and damper would work. But it would need to be large enough to clean the screen easily. The opening will also serve as an access opening to look at the damper and service it, as well. Do not skimp on the size of the opening; too small and it becomes useless and you’ve installed an opening and elongated the sleeve for nothing. Now, however the sleeve gets longer and the whole fan assembly is cantilevered further out into the space; a minor concern for being able to service the screen and damper.

Here are some suggested solutions for better accessibility.

FOR DUCTED SYSTEMS:

For systems that are ducted behind the louver, I like to install the screen on the outside of the louver. Selecting a screen and fasteners of the same material as that of the louver will work best as it eliminates galvanic corrosion between the louver and screen, which can occur when different materials are used.

If the louver opening is located low, close to grade, it can be accessed for cleaning without much trouble. A bit higher up and ladders may be needed. However, if close to grade where people may congregate, you may want to consider using vandal-resistant fasteners to mount the screen onto the louver.

If it is too high and not practical for cleaning (from the outside), then locating the screen behind the louver inside is an option. However, then you need an access door or sheet metal panel on the bottom or sides of the ductwork, close to the louver for access to cleaning. So a large enough access door or panel so that someone can easily stick their arm or hand inside while using a brush to clean the screen is advisable.

Of course, having access doors or panels in the ductwork now introduces another concern: air leakage around the perimeter of the door or panel.

Over time, the doors and panels may deform due to system pressure and/or mishandling, and this affects perimeter sealing. So, ensure the gaskets on the doors/panels are inspected regularly and maintained. For low pressure systems, deformation is not too much of a problem; however, the larger the door/panel opening, and hence its perimeter length, the greater the potential for deformation. I’ve seen entry doors on large air-handlers (operating with moderate to large negative or positive pressures) that did not close correctly, inducing leakage either because of bad gaskets or deformation that has occurred over time.

FOR UNDUCTED SYSTEMS:

Unducted systems include those that are simply louvered openings – sans equipment – in walls for ventilation movement of airflow in or out. Thus, again, if the louver is low and easily accessible from grade, mount your screen on the outside of the louver. When the louver is too high and impractical to access from grade, and the system is not ducted – and doesn’t have equipment mounted inside behind the louver – then mount the screen on the inside. With this arrangement, the screen is visible and accessible from the spaces’s floor (provided the floor level isn’t too low). At higher elevations above grade, if there is fan equipment mounted behind the louver, then locating the screen between the louver and fan is best to protect the fan from outside interference or creatures. But also locate an access door or panel in the fan sleeve between the screen and fan to access both the screen and the backside of the fan.

FINAL THOUGHTS:

Screens mounted on the inside, behind a louver, will leave the louver exposed. If the system operates rarely, you may find that birds will try to build nests between the louver blades and screen. Realize that birds will attempt their nest building during the start of spring (in the northern states), so if the system is inoperable then, you may have a problem.

Always locate your screens where they can be accessed for cleaning, and if you need to add an access panel or door, make it large enough to comfortably get into the opening to do that cleaning.

Also, don’t use insect screens unless insects are truly a liability to the systems or the spaces inside. And as expected, insect screens will get dirtier and clog much faster than a bird screen. Insect screens are those with a 3/32 inch (0.093 inches) mesh spacing or less, however when one only needs to consider larger insects, a screen with a mesh of 3/8 inch (0.375 inches) could keep the larger bugs out and still not be too restrictive (to airflow). Bird screens are those with at least a 1/2 inch (0.50) mesh spacing or greater.

As noted earlier, mounting screens on the outside surface of a louver, exposed to weather, would be best fastened with screws made from the same material as the louver. The louver, screen and fasteners should generally be made of the same materials (steel or aluminum or stainless) to eliminate galvanic corrosion between parts made with different materials.

If vandalism is a concern, then consider fastening screens with vandal-proof fasteners or simply tack welding the screens to the louver.

Remember, equipment needs to be kept clean for best performance, performance that should stay close to “design conditions” as long as possible. So, locating your equipment to allow access is important. It is not a minor detail.

REFERENCES:

1 Games, G., HPAC Engineering, December 2019, “Fan Equipment Mesh Screen Cleanliness and Performance Effects”.

##########

CONTACT:

Email the author at: [email protected].