Forensic Engineering: How Much Water Can Your Building Hold?

Second in an occasional series...

By JAMES P. WALTZ, P.E., C.E.M., DABFET, FCABE

As a member of the HPAC Editorial Advisory Board for over 20 years, and as a fellow and founding chair of the first U.S. chapter of the British Chartered Association of Building Engineers (CABE), it seems appropriate to share some of my experience as a forensic engineer and as an expert witness in nearly 70 cases.

- To read the first article in this series, click here.

This case involved a large chilled water pipe serving a new building on a college campus. One of the nice things about chilled water is that the pressures and temperatures allow underground distribution in a campus situation using high performance PVC piping. Similar to most underground thermal distribution systems, the piping system employed was a factory-fabricated, pre-engineered system which needed to be installed in strict accordance with the manufacturer’s directions.

Now on this campus, heating was supplied to the buildings by an underground high pressure steam system, and this building was supplied with both chilled water and steam. Being a slab-on-grade building, both chilled water and steam traveled underground, and then came up through the floor into a vertical chase or shaft just inside the building, and proceeded from there to the various HVAC equipment in the building. Because PVC piping is relatively weak compared to metallic piping, the manufacturer instructed that the PVC piping transition to metallic piping while still underground.

In this case, the installing contractor did not transition until the piping was in the vertical chase – and did not insulate the PVC piping for the last two feet or so below the flange joining the PVC piping to the metallic piping in the chase. This did not cause any difficulties under normal operating conditions, even though the uninsulated PVC piping was immediately next to the steam piping at some 350+ degrees F.

One of the challenges of operating a steam system is that it cannot simply be taken out of service for a holiday period. Steam and condensate return piping must be energized quite carefully after an outage, both due to the extensive thermal expansion of the piping and the huge condensate load that occurs when first bringing the system on line. This can result in excess condensate “hammering” elbows, and the system being waterlogged in the early hours of energizing the system. The net result is that, for shorter holidays especially, steam systems are often left energized, while the chilled water is shut down.

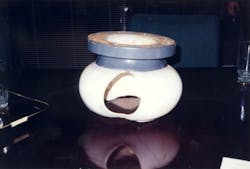

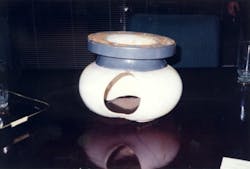

Such a situation occurred over the Independence Day weekend holiday. And actually, this was probably one of many times this had happened. As the accompanying photo shows, however, it was one time too many.

As can be seen, that bit of un-insulated PVC chilled water pipe was seriously softened by its proximity to the 350+ degree adjacent steam line, and became a bit like a child’s toy balloon – until it failed.

Now this in itself would not have been that serious a problem but for a feature of the chilled water system on the campus. That feature was a million-gallon chilled water storage tank located just down the street. Thermal energy storage is a good thing as on-peak electricity in that region costs 5 to 10 times that of middle-of-the-night electricity.

So, a while after the pipe split and the spray of chiller water penetrated the (now wet and well-steamed) sheetrock of the chase, causing a building alarm or a passerby to alert campus security. When they arrived, they found the water about halfway up the exterior doors of the building.

Curiously, when I asked the thermal storage tank design engineer if he had ever considered adding a pair of emergency, self-powered, level-controlled shut-off valves at the storage tank, he asked “Why would you ever want to do that?”

##########

Based in West Sacramento CA, the author is president of Energy Resource Associates Inc., specializing in turnkey forensic examination and engineering of infrastructure renewal for existing-building mechanical, electrical, control, and structural systems. Waltz is a member of the Association of Energy Engineers Hall of Fame, and a fellow of the first U.S. chapter of the Chartered Association of Building Engineers (CABE – UK), which he chairs. Waltz joined the HPAC Engineering Editorial Advisory Board in 2000. Contact: [email protected]