Optimizing Building Automation Systems With Quality Cable

By DANIEL D. DUNAR, Resideo Technologies

By 2026, the global building automation market is projected to grow to $112.1 billion, creating many new opportunities for systems engineers, product specifiers and contractors.1 While investing in new systems can be costly, integrated building automation systems (BAS) save end users money and lower energy usage long-term. According to the American Council for an Energy-Efficient Economy (ACEEE), an integrated BAS system can realize 30-50% energy savings, greatly reducing costs.2

Though often overlooked, effective, high-quality cabling plays an integral role in BAS performance and is necessary to establish an infrastructure that readily adapts to future needs. Designed to optimize building operations, a reliable cabling infrastructure protects your capital investment in automation technologies and strengthens system longevity.

Role of Network Infrastructure

BAS systems integrate independent building components and are designed to simplify system management, maximize comfort and increase energy efficiency. These systems combine wired and wireless communicating devices to create one complete system. Wireless communicating devices are typically easier to install in retrofit jobs, while wired devices offer greater reliability and less complexity.

Regardless of the approach, a strong cabling backbone is critical to simplify system management because it increases capabilities and establishes a cabling structure for ongoing, easy system adaption to future business needs.

Cable Selection Dictates System Success

As buildings grow more interconnected and sophisticated, the cabling backbone serves as the point of connection between critical devices and locations within a system. This structure allows for easy system expansion using either wired or wireless communicating devices, thus future-proofing your investment.

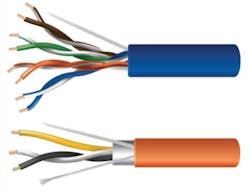

In a standard commercial building automation system, there are two critical types of cable: communication and signal cables. The following explores specific characteristics these cables must have to protect system longevity.

Communication cable transmits data at high speeds between the brains of a building automation system to localized controllers – sometimes over thousands of feet. Communication cables include a variety of construction, including category cable for Ethernet and serial digital cables designed for protocols such as EIA-232 or EIA-485. When the incorrect cable is used, it can cause distortion and interruption that threatens entire system functionality.

All high-quality communication cable will contain the following qualities:

- Low Capacitance: Total capacitance is dependent on cable design and the length of the run. Attributes such as insulation thickness, insulation material, and the presence of shielding determine the mutual capacitance between conductors in a cable, which is expressed in capacitance per foot, or meter, on the cable’s specification. Multiplying this attribute by the length of the run yields the total capacitance. Limiting capacitance ensures more effective signal transmission and more reliable system performance;

- Pure Copper Conductors: The National Electric Code (NEC) requires pure copper conductors for these cables. Pure copper limits resistance and lowers voltage drop for reliable, long-term performance. It also provides the physical qualities for secure and lasting connections;

- Consistent Impedance Levels: Confirm that the chosen cable’s listed impedance matches the device’s impedance. Mismatched impedances can cause incomplete signal transfer, lower signal strength, and cause distortion on the transmission line.

Signal cable transmits signals between controllers and BAS devices over relatively short distances. The cable you need is device-dependent, meaning the device dictates the amount of power the cable must deliver, and therefore, cable selection

When choosing a signal cable, it’s important to consider the following qualities:

- Appropriate Gauge Size: Choose cable that is sized for the current and power requirements of the connected device. The longer the cable run, the greater the voltage drop, so larger gauge sizes should be used for longer cable runs. Undersized cable is unable to meet device requirements and threatens system performance;

- Pure Copper Conductors: Pure copper conductors reduce DC resistance and protect signal quality.

Communication and signal cables should also be listed by a nationally recognized testing laboratory such as UL or ETL. A listing signifies that a cable meets all required fire and safety standards and has been manufactured using high-quality plastics with the necessary additives. Don’t sacrifice the performance of your BAS technologies by leaving them up to the mercy of inferior wire.

Follow Device SpecificationsNot all devices are created equal, and some have specific cabling requirements that need to be met for successful system integration. To ensure you choose the correct cable, review the device’s specifications, which often call for such requirements as gauge size, impedance, capacitance, etc. Following these guidelines can help you streamline installations and make sure you get your cabling right the first time.

Adhering to BAS Standards

When designing a building automation system, following industry-recognized standards can set systems up for success. In the United States, the Telecommunications Industry Association is accredited by the American National Standards Institute to establish cabling standards. It has set the following standards to guide the development of structured cabling and building automation systems:

- ANSI/TIA 568 – Provides insight on structured cabling installation guidelines, cable performance requirements, cable design and restrictions on use in application;

- ANSI/TIA-862-B – Specifies minimum requirements for BAS systems, including cabling design, installation requirements, system architecture, and specific components.

Individual communication devices also dictate the protocol a system needs to follow. BAS protocols establish mechanisms by which automated building devices can communicate. A few examples of these protocols include BACNet® and LonWorks®.

Though not required by law, building automation protocols and standards ensure systems are compliant with all relevant codes – further protecting your cable investment and overall system performance.

Choose Cable That Drives System Performance

No matter the size or complexity of the BAS system, the cable you choose will dictate system performance. Don’t let your investment in the latest technologies go to waste – invest in reliable cabling designed to optimize system performance and longevity. This can save you time and money, and ultimately, help your business to win more bids.

An integrated building automation system opens up opportunities for businesses to reduce their energy use and save money, benefiting their bottom line and the planet. Take advantage of the growing market opportunity and protect your cable and system investment by choosing cable from a manufacturer you can trust.

##########

Footnotes

1 “Building Automation System Market.” MarketsandMarkets, 2021, www.marketsandmarkets.com/PressReleases/building-automation.asp;

2 King, Jennifer, and Christopher Perry. 2017, Smart Buildings: Using Smart Technology to Save Energy in Existing Buildings, www.aceee.org/sites/default/files/publications/researchreports/a1701.pdf.

##########

Based in Pleasant Prairie WI, the author holds an electrical engineering degree from the University of Wisconsin-Madison. Since 2018, he has been a marketing leader for Genesis Cable, a Resideo Technologies brand.