Boiler, Water Heater Advances Boost Efficiencies in Combination Plants

By CHRISTIAN ZAPATA, AERCO International

For combination plants featuring systems designed to support space heating (SH) and domestic hot water (DHW), several important factors need to be addressed by the design engineer. Among the most important considerations are:

- Accounting for different temperature requirements of SH and DHW;

- Prioritizing which load to satisfy;

- Redundancy for the SH and DHW.

Advances in boiler and indirect water heaters create design opportunities to address these factors, improve system-wide efficiency, and create cost savings. Among the developments are dual returns, smart controllers that optimize combination plant operation, and water heater bypass lines.

Smart Controllers Leverage Swing Boilers

Smart controllers handle the different temperature requirements by designating boilers to be assigned to SH while others are allocated for DHW. Swing boiler(s) that can alternate between SH and DHW are also assigned and separated using swing valves.

Load prioritization is managed by a smart controller, as well. For example, when the DHW boiler(s) cannot meet their load, the controller directs the swing valves to divert the swing boiler(s) from SH to DHW. As per ASHRAE, it is assumed that both SH and DHW peak loads may not happen concurrently. This switching capability offers a major benefit in reducing the number of boilers required to meet plant peak load, thereby shrinking the system footprint. Additionally, initial plant cost is lowered, since less equipment and fewer controls are required.

Dual Returns Increase Efficiency

Another benefit to this design is it lends itself well in the utilization of boilers with dual returns. Because the space heating and domestic loops are separated, the dual returns boilers split high- and low-temperature return water to increase the heat exchanger’s condensing zone. Using this approach, efficiency increases by as much as 6%, depending on the upper to lower inlet flow rate ratios and return water temperatures.

Boiler Supply Bypass Advantages

For more operational savings in this combination plant design, indirect water heaters with boiler supply bypass can be paired with the dual return boilers. This bypass line diverts excess boiler water back to the system or the boiler’s upper inlet to ensure condensing temperatures are always returned to the lower inlet. System-wide efficiency is further increased utilizing indirect water heaters with this design.

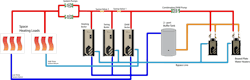

Figure 1 illustrates the combination boiler plant with dual return boilers for SH and DHW generation. DHW generation is through brazed plate water heaters with boiler water bypass. The boilers and water heaters in this configuration utilize smart controls to prioritize loads, and provide N+1 redundancy for both systems.

A boiler is dedicated to serve the DHW load. A swing boiler is assigned to serve SH by default and assist the DHW load, as needed. Swing valves separate the heating, swing, and domestic boilers. A combination system pump runs continuously to provide boiler water to the water heaters. To dampen fast domestic load transitions and minimize boiler cycling, a 2-port buffer tank is utilized.

The smart controller sequences the boiler plant to obtain maximum system efficiency by running as many boilers as available, each operating at its most efficient firing rate. The smart controller also offers inter-communication between the boilers and water heaters, enhancing user experience with an advanced, intuitive interface.

Parameter settings and sensory data can be monitored on the manager boiler or via mobile app (Figure 2).

Figure 3 summarizes the behavior of the aforementioned combination plant. Swing valve positions, state of the swing boiler and DHW boiler, as well as the condition of the combination system pump are all summarized. In this application, the swing boiler supports SH by default.

To illustrate load prioritization, consider the SH boilers are operating at full capacity. If the smart controller determines that there is no domestic load, the DHW boiler can shift into SH for additional capacity. Conversely, the smart controller allows the swing boiler to shift to DHW mode, if the DHW boiler is operating at close to capacity and the SH boilers are operating at less than full capacity.

When SH loops with different return temperatures are incorporated in the design, loops with lower return temperatures can be brought back to the lower inlet. By doing so, the advantages of dual returns are further highlighted and results in increased efficiency, as shown in Figure 1.

Rather than blend separate zones, the lower temperature zones/systems can be piped separately to the lower boiler inlet. Overall thermal efficiency is raised, allowing the boiler to be in condensing mode for longer periods throughout the year.

Conclusion

Advances such as dual returns, smart controllers, and supply bypasses present engineers with design advantages to improve the efficiency of combination plants. These advanced features can optimize space heating and other applications, such as indirect DHW, higher ΔT zones with lower return temperatures, air preheat, and heat pump injection.

##########

Based in Bergenfield NJ, the author is a product solutions manager for AERCO International, a WATTS brand company. He joined AERCO in 2000 after earning a BS in Mechanical Engineering at the New Jersey Institute of Technology.