Using UV-C Light to Disinfect Room Air and Surfaces

By LAURA COWLEY, P.E., LEED AP, B&H Engineers Inc., and PIETER De BOD, Pr. Eng., LEED AP, WSP USA

Ultraviolet light (UV) technology is a non-chemical approach to disinfection and has been used and researched for decades. This article investigates using UV-C for disinfection of room air and surfaces and ability to effectively inactivate airborne viruses like the coronavirus 2019 (COVID-19) pandemic. Aspects like safety, lamp technologies and applications are explored.

UV radiation is a type of electromagnetic radiation, present in the range between visible light and X-rays and is divided into UV-A (315 nm to 400 nm), UV-B (280 nm to 315 nm), and UV-C (200 nm to 280 nm). UV radiation is undetectable by the human eye but when it falls on certain materials it may cause them to fluoresce. UV radiation is artificially created using UV lamps.

UV-A and UV-B are generally not effective to inactivate viruses. However, UV-C is known to be effective in inactivating viruses and disinfecting surfaces,[i], [ii] water,[iii] and air [iv] by killing bacteria, mold spores and fungi. When UV-C is used for disinfection, it is called Germicidal UV (GUV).

The use of GUV lamps and lamp systems to disinfect room air and air streams dates to about 1900.[v] Early applications using UV light predate antibiotics and vaccines, and were used for air disinfection in schools, hospitals, and other public buildings. A germicidal lamp is an electric light that produces UV-C light.

On a microscopic level, UV-C photons photochemically interact with the RNA and DNA molecules in a virus or bacterium, causing mutations that prevent replication. This leads to the death of almost all bacteria and renders these microbes non-infectious.

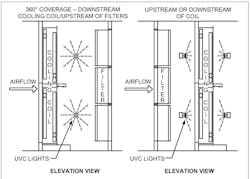

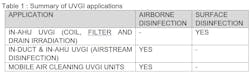

IN-AHU UVGI (COIL, FILTER AND DRAIN IRRADIATION)

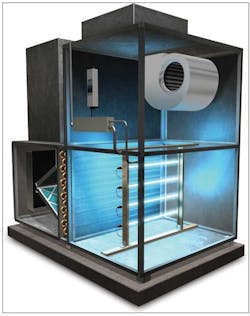

The principal design objectives for installing UV-C lighting systems in air handling units (AHUs) are to prevent the growth of bacteria and mold on system components like coils, filters and drain pans.

A large dose of UV-C light can be delivered with a low UV-C irradiance because of the constant exposure time to the mentioned AHU components. Coil surface irradiance levels in the order of 1 μW/cm2 are effective, though 50 to 100 μW/cm2 is more typical.[i]

Cooling coil treatment systems have the two-fold objectives of maintaining coil performance and minimizing energy use by reducing air-side flow resistance and increasing the overall heat transfer coefficient relative to a conventionally maintained, mechanically and chemically cleaned coil.

A field study in a hot environment, experienced a 22% reduction in pressure drop and 15% increase in air-side heat transfer coefficient after less than two months of surface treatment system operation.[iii]

In most cases, the lowest maximum velocity in a system occurs inside an AHU, increasing the effectiveness of in-AHU UV-C lights due to increased exposure time. In-AHU UV-C lights also treat air from many spaces and simultaneously irradiate cooling coils and condensate pans, increasing overall benefits of the system.

At an air velocity of 500 fpm (2.54 m/s), a typical irradiance zone of 7.8 ft (2.4 m) in length achieves a 1 second exposure. Generally, in-duct or in-AHU systems should be installed in a location that can provide a minimum of 0.25 second of UV exposure; otherwise, system cost and power consumption will be excessive.[iv]

Proposed ASHRAE Standard 185.1 provides a testing method for UV-C lights in-AHU and in-duct applications to inactivate airborne microorganisms.[v]

Advantages

- Suitable for all climates;

- Enclosed system (exposure to humans reduced);

- Treats recirculated air from a centralized location;

- Prevents mold and biofilm on cooling coils.

Disadvantages

- Potential occupational exposure when safety procedures are not followed;

- Expensive to install;

- Requires UV-save filters;

- Possible material degradation (i.e. filters).

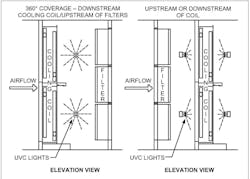

IN-DUCT AND IN-AHU UVGI (AIRSTREAM DISINFECTION)

The principal design objective for UV-C in duct or AHU is to distribute UV energy uniformly in all directions throughout the length of the duct or AHU, and to deliver the appropriate UV-C dose to air moving through the irradiated zone with minimum system power.

It should be noted that it is not very effective to prevent transmission of an airborne virus from an infected person to a non-infected person in the same room.

To determine the dose value requires analysis of the entire system.

Typically, single-pass, ducted systems are used. In-duct air disinfection systems should be designed to have the desired single-pass inactivation level under worst-case conditions of air temperature (minimum worst-case conditions of air temperature (minimum and maximum temperatures in duct) and velocity (maximum allowable duct velocity) in the irradiated zone. The worst-case performance to reflect the combined effect of the: (a) number/power of UV-C fixtures; (b) air residence time (which is inversely proportional to air velocity); (c) lamp/ballast characteristics (including the effect that the wind chill factor and lamp depreciation has on the lamp).

Lamps may be located anywhere in an air duct system provided their position allows for good maintenance access.

Advantages

- Suitable for all climates;

- Enclosed system;

- Treats recirculated air;

- Treats cooling coils to keep clean of mold;

- Recommendations and guidelines available.

Disadvantages

- Potential occupational exposure and lamp distance;

- Expensive to install and maintain in resource-limited settings;

- Degrading filter media;

- Possible material degradation.

GERMICIDAL IRRADIATION DOSE

For any UVGI application, the ability of UV-C to inactivate micro-organisms is a function of the UV dose. A key characteristic of germicidal lamps of any sort is the UV-C radiation dose.

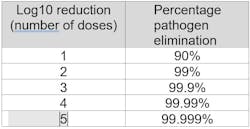

The required dose depends on both the pathogen species to be eliminated and the desired degree of reduction. For example, eliminating 90% of Escherichia coli O157:H7, the bacterium that can cause sometimes fatal food poisoning, requires 1.5 mJ/cm2; doubling the dose eliminates 99%, tripling eliminates 99.9%, and so forth. This is referred to as log10 (“log-ten”), or more commonly as “log,” reduction (Table 2).

The International Ultraviolet Association published a compilation of dose requirements for many different pathogens, but viruses on average require a dose of about 20 mJ/cm2 for 90% reduction when directly exposed to the UV-C radiation (IUVA undated).

The basics of determining the radiant energy levels to a surface are as follows: [vi]

- Length of exposure -- Increased source intensity can decrease necessary exposure time;

- Intensity of source -- UV-C lamp and equipment manufacturers normally provide the intensity of a given source (lamp or fixture) at a given distance. A distance correction factor may be needed when calculating a desired dose or intensity for a surface. UV-C energy follows the same inverse square law for intensity as visible light and other electromagnetic sources: the amount of energy at the surface is measured in proportion to the square of the distance from the energy’s source (the UV-C lamp), assuming no loss through scattering or absorption. Temperature and airflow corrections may also be necessary, depending on the location of the application. The intensity of a source is given in power per unit area (i.e., μW/cm2);

- Distance from source to surface -- In a point irradiation application, the distance is relatively easy to calculate. Calculating time requirements and intensity levels for a three-dimensional object or space is more complex. The varying distances from the source are the first challenge, because the object, itself, creates a shadowing effect, and any shadows from the local environment must be taken into consideration (for example, the back surface of an object that did not get direct light).

EFFECTIVENESS OF UV-C TO INACTIVATE SARS-CoV-2

Various articles[vii] suggest that the SARS-CoV-2 virus (responsible for COVID-19) can be inactivated by UV-C at 254 nm, if directly illuminated by UV-C at the effective calculated dose level. UV light exposure is a direct antimicrobial approach,[viii], [ix] and its effectiveness against different strains of airborne viruses has been established since the 1900s.[x], [xi]

Therefore, low-dose-rate far-UV-C exposure can potentially and safely provide a major reduction in the ambient level of airborne coronaviruses including SARS-CoV-2, while staying within the current regulatory dose limits.

UV-C SAFETY

UVGI lamps pose a health hazard to the eyes and skin. Only trained maintenance staff with UV-specific training should be allowed to work on UV-C systems, or work in any area where UV-C is present. All UV-C systems require periodic inspection, maintenance, and lamp replacement to ensure proper system performance. Individuals working on UV-C must be protected to prevent UV hazards to the eyes and skin. UV-C should not be used to disinfect the hands since mild erythema (sunburn) occurs when skin is exposed to UV-C.

The CDC has provided guidelines for the use of UVGI lamps in upper rooms and AHU’s as a supplemental control measure for air disinfection.[xii], [xiii], [xiv]

__________________________________________________________

Based in Dallas, TX, author Cowley is an electrical engineer and vice president at B&H Engineers Inc. She can be reached via email at: [email protected]. Also based in Dallas, co-author De Bod is a mechanical engineer and senior associate and supervisor at WSP USA. Contact him at [email protected]. The pair recently presented on this topic at the 2022 LightFair Conference and Trade Show in Las Vegas.

_________________________________________________________

[i] Downes A, Blunt TP. The influence of light upon the development of bacteria. Nature. 1877;16(402): 218;

[ii] Downes A, Blunt TP. Researches on the effect of light upon bacteria and other organisms. Proc Royal Soc London.

1877; 26: 488-500;

[iii] Grant KC. Sterilization of polluted water by ultra-violet rays. Engineering News. 1910; 64 (275);

[iv] Wells WF, Wells MW, Wilder TS. Viability of B. coli exposed to ultra-violet radiation in air. Science. 1935; 82: 280-1;

[v] Reed, N.G. 2010. The history of ultraviolet germicidal irradiation for air disinfection. Public Health Reports. 125:15-27;

[vi] ASHRAE Applications Handbook – 2019, Chapter 62;

[vii] ASHRAE Applications Handbook – 2019, Chapter 62;

[viii] Bahnfleth and Firrantello 2017; Firrantello and Bahnfleth 2017a) and Singapore (Wang et al.2016a, 2016b)

[ix] ASHRAE Applications Handbook – 2019, Chapter 62.

[x] ASHRAE Position Document on Filtration and Air Cleaning, 2021. P 10.

[xi] ASHRAE Applications Handbook – 2019, Chapter 62.

[xii] Darnell ME, Subbarao K, Feinstone SM, Taylor DR. Inactivation of the coronavirus that induces severe acute respiratory syndrome, SARS-CoV. J Virol Methods. 2004;121(1):85-91. doi:10.1016/j.jviromet.2004.06.006.

[xiii] Buonanno, M., Welch, D., Shuryak, I. et al. Far-UVC light (222 nm) efficiently and safely inactivates airborne human coronaviruses. Sci Rep 10, 10285 (2020). https://doi.org/10.1038/s41598-020-67211-2.

[xiv] Kowalski, W. J. Ultraviolet Germicidal Irradiation Handbook: UVGI for Air and Surface Disinfection. New York: Springer, (2009).

[xv] Budowsky, E. I. et al. Principles of selective inactivation of viral genome. I. UV-induced inactivation of influenza virus. Arch. Virol. 68(3-4), 239–47 (1981).

[xvi] https://innovationorigins.com/dangerous-UVC-light-can-inactivate-the-coronavirus-a-study-by-signify-and-boston-university-claims/

[xvii] Sehulster L, Chinn RYW. Guidelines for environmental infection control in healthcare facilities – Recommendations of the Centers for Disease Control and the Healthcare Infection Control Practices Advisory Committee (HICPAC). 2003;52(RR10):1-42.

[xviii] Jensen PA, Lambert LA, Lademarco MF, Ridzon R. 2005. Guidelines for preventing the transmission of Mycobacterium tuberculosis in health-care settings, 2005. Morbid Mortal Weekly Rep. 2005;54(RR17):1-141.

[xix] Centers for Disease Control and Prevention; and National Institute for Occupational Safety and Health. Environmental Control for Tuberculosis: Basic Upper-Room Ultraviolet Germicidal Irradiation Guidelines for Healthcare Settings. Washington, DC: Department of Health and Human Services; 2009.

##########