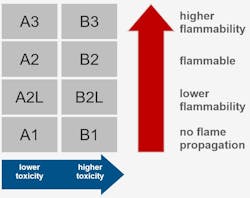

VRF and A2L Refrigerants: What Engineers Need to Know

By JOSEPH GUERIN, VRF Specialist, Trane Technologies

Last spring, my colleague Laura Michel and I presented an HPAC Engineering webinar entitled,“What Engineers Need to Know about The Impact of A2L Refrigerants on VRF Systems.” It was an overview of the upcoming changes to variable refrigerant flow (VRF) system designs, and it was very well-received by HPAC's online audience.

Attendees tuned in from all 50 U.S. states and 13 other countries. The high attendance and numerous questions submitted highlighted the importance of this discussion and the industry's desire for more information on this compelling topic. In fact, the number of questions would have required several hours to answer had we addressed them all on the day of the presentation.

With that in mind, we decided to present the information here, as well, incorporating some more recent significant changes to the ASHRAE® 15 safety standard that could have important ramifications for VRF and Ductless projects.

- To see the original webinar on demand, click here.

As an industry, we have had over a century to discuss, understand, and agree on the application of air conditioning. Other countries have been using A2L refrigerants for more than a decade, but here in the U.S., we have only been discussing them for VRF and Ductless applications over the last few years. So, suffice it to say, our collective understanding of the entire topic is still in its infancy.

So let me start with the good.

While some geographies may be hesitant to use A2L refrigerants in certain equipment, the demand for Ductless/Mini-Split products is still 7.8% higher than last year, according to the latest Air-Conditioning, Heating and Refrigeration Institute (AHRI) market data through July of this year. Overall, this shows that our industry did not pull back when Ductless products transitioned to R-454B. Rather, it surged forward with the adoption of the new refrigerants. If this is any indication of where VRF is headed, it would be expected for VRF to continue its powerful growth in the industry as a very efficient and sustainable system.

Side benefits

A side benefit to VRF equipment using A2L refrigerants is the addition of leak detection and safety shut-off valves. To be perfectly blunt, if VRF does not have these items, the projects where it can satisfy the ASHRAE 15 safety standard are very few and far between.

Multitudes of engineers and contractors in our industry have been requesting these features for years. So, many are now thrilled to see them included as standard in this next generation of VRF equipment. Primarily, these new features will keep occupants safer and will give building owners greater peace of mind, just knowing that they are in place.

But they also assist with troubleshooting if something does go wrong. For instance, now that we have detectors, we can locate a refrigerant leak much faster and more easily. Better yet, the system only needs to isolate the units that detect refrigerant, allowing the remainder of the system to continue operation (Interpretation IC 15-2022-7).

One of the other major changes since last spring's webinar that most deem as "good" is Addendum 'A' to ASHRAE 15-2024. This addendum added an additional exemption to the shaft enclosure requirement, saying that if the piping was tested in accordance with Section 9.13, it is exempt from requiring a shaft. However, if that piping is placed into a shaft enclosure anyway, it will still require ventilation for A2L refrigerants. While the ventilation requirement remains, this is still a welcome relief that allows VRF and Ductless designs considerably more leeway.

Codes in conflict

As the safety standard continues to evolve, code compliance is another conversation the industry is now having. The International Mechanical Code (IMC) and ASHRAE 15 have conflicting information in a few areas, leaving engineers and contractors to wonder whether they should follow the latest national safety standard, or follow their local code.

Thankfully, this conversation has made its way to the local level, where some jurisdictions are modifying their own regulations to provide a more harmonized standard for local use. For example, the North Central Texas Council of Governments (NCTCOG) approved regional amendments to the 2024 IMC, explicitly incorporating ASHRAE 15-2022 verbiage. To see the actual document, click here.

In a similar fashion, the Board of Building Regulations and Standards (BBRS) in Massachusetts issued an advisory stating that systems compliant with the updated ASHRAE 15-2022 standard are also compliant with the 10th-Edition Massachusetts building code, effectively bridging the gap with IMC 2021 and enabling projects to move ahead without costly restrictions. To see the document, click here.

For jurisdictions not taking this approach, the industry has another avenue for code compliance.

Engineers and contractors are allowed to file for a variance citing future codes. The publication of ASHRAE 15-2024 came one year earlier than usual and was relatively unnoticed compared to the publication of the 2022 version. But this was quite significant because it establishes a new three-year cycle that coincides with the model code cycle.

The ASHRAE 15-2024 standard can now be submitted in public comments to the code councils for incorporation into the IMC 2027 code. Orchestrating the safety standard and code in this way will give the industry a cohesive guideline moving forward. In fact, we’re already witnessing that come to pass. As just one example, Section 1109.2.5 will be modified so that Exception 2 to pipe shafts recognizes A1 as well as A2L refrigerants.

- To see the related International Code Council story, click here.

Potential hurdles

While these changes are positive for VRF and Ductless applications, it would not be responsible if we didn’t also discuss the sticky issues that remain.

As already mentioned, if a pipe shaft is used, regardless of whether it is not required, that shaft must be ventilated. An addendum to remove this requirement for A2L refrigerants is still under review, and its acceptance is not a foregone conclusion, despite the broad support it would likely garner in our industry.

Another stickier topic that still has many scratching their heads is unoccupied, energy-dense spaces in buildings, i.e. IT closets, server rooms, etc.

The requirement to evaluate occupied AND unoccupied spaces for A2L refrigerants is proving quite difficult in these situations because of the high capacity-to-volume ratio these spaces see. It remains to be seen whether the safety standard will give any leniency to these unoccupied spaces. But for now reducing system charge, increasing effective dispersal volume, or using mitigation controls are the only levers we can pull at this time.

Lastly, ASHRAE recently cleared up the question on how VRF Branch Controllers should be evaluated. The safety standard does not specifically mention the terms “Branch Controller,” “Refrigerant Distribution Box,” or anything similar, so until recently, the best understanding was to treat a Branch Controller as part of the refrigerant piping and, therefore, exempt under Section 7.2.3.1.1.

But Interpretation IC 15-2022-12 now establishes a Branch Controller as separate from refrigerant pipe, therefore requiring its own effective dispersal volume calculation. Reducing system sizes and increasing dispersal volume are still options, but given the large refrigerant charges in VRF systems, this could still prove difficult for certain projects.

Thankfully, another option exists which is a ventilated enclosure. ASHRAE defines this as “a type of equipment enclosure that includes an integral ventilation system that will prevent refrigerant leaked inside the equipment enclosure from escaping into the space surrounding the equipment enclosure.”

It remains to be seen how each manufacturer decides to handle this, but with the A2L transition date on the horizon, we should know very soon.

If the webinar presented in April didn’t address all your concerns, I hope these updates offer additional clarity and reassurance. ASHRAE is not increasing the burden on VRF design and installation but rather recognizing and providing the framework to design smarter and safer systems.

With thorough testing, strategic code citation, and local expertise, you should find that these new standards and regulations pave the way for greater innovation and efficiency in VRF and Ductless systems.

#####

Based in Maryland, the author is now in his 11th year with Trane. Today, he is Trane Technolgies' Mid-Atlantic VRF Ductless Sales Specialist. In his current role, he is primarily responsible for overseeing and supporting the design and application of commercial VRF projects in the region. As an active ASHRAE member, he has taken a keen interest in the 2022 update of the ASHRAE 15 Safety Standard, exploring its implications for VRF and Ductless system designs. Email: [email protected].