AI: Putting Energy Intelligence into Cleanrooms

By Zuhair Hasan, PhD, PE, LEED AP, and Kurt Burrell, PE, HFDP

Cleanrooms are specifically designed, constructed, and operated spaces that control the concentration of airborne particulates and other indoor environmental factors, including humidity, temperature, air pressure, speed, quality, and flow direction. The control of cleanroom environmental factors is critical for sensitive equipment, high-precision manufacturing, personnel safety, and the quality of products and research.

In the past five years, the demand for cleanroom construction has rapidly increased due to increased competition and advancement in the electronics industry, aerospace components (Zhao et al., 2023), and increased demand for research on viruses such as COVID-19. Cleanrooms are considered critical to the operation of several facility types with important functions and high-precision manufacturing, such as semiconductors, microelectronics, aerospace, biotechnology, food processing, and pharmaceutical industries.

However, such spaces are also considered to be energy-intensive in comparison to other facility occupancy types. Cleanrooms can consume up to 100 times more than typical office buildings (Zhuang et al., 2021). In 2021, the energy consumed by cleanrooms globally was approximately 100 billion KwH (Zhao et al., 2023), which makes them second only to data centers. Additionally, Liu et al. (2021) reported that pharmaceutical cleanrooms, alone, consume up to 25 times more energy than commercial buildings.

Despite the enormous energy consumption in cleanrooms, designers lack a clear understanding of energy-efficient strategies to mitigate this intense consumption. This article provides insights into some energy-efficient strategies that designers of cleanrooms can use to address this problem, specifically the air changes per hour (ACH) factor. Cleanroom design is primarily driven by the cleanliness and particulate count within the unit volume of air. The particulate count is controlled by the frequency with which the air inside the cleanroom is changed and filtered per hour. Therefore, airflow is the most significant factor driving the initial and operational costs of cleanrooms.

Few standards set the guidance for ACH requirements based on cleanroom classification, such as the ISO-14644-1 and USP 797/800. In the U.S., the Federal Standard-209E was the governing standard for cleanroom classifications until 2001.

For example, a cleanroom with 100 classification (per FED-209) is equivalent to ISO classification 5, which requires limiting particles of 0.5 µm or larger not to exceed 100 per cubic foot of air inside the cleanroom.

While design standards provide a range for ACH requirements for each clean room class, they do not specify the exact amount (Liu et al., 2021). Therefore, supplying conditioned air can be twice as much as needed to control particulate concentration, thereby avoiding potential risks that cause massive energy waste. Consequently, maintaining the required operational environmental conditions inside cleanrooms and minimizing energy consumption becomes a challenging mission for design engineers.

Artificial Intelligence (AI) for Energy Intelligence (EI)

AI can be defined as computerized algorithms that can process tasks at or exceeding human intelligence levels through perception, interaction, and learning (Farzaneh et al., 2021). AI differs from preprogrammed automation systems in its learning capabilities and the capability of changing its own behavior with no significant external interference from programmers (Farzaneh et al., 2021).

Therefore, we define energy intelligence as the continuous, dynamic, instantaneous diagnosis of environmental factors and system control and adjustments of operating building engineered systems to maximize energy efficiency and extend the service life of systems and components through computerized algorithms with learning and behavior-changing capabilities with no significant external intervention. AI can be used in optimizing cleanroom operations by using real-time data and predictive algorithms – a subset of machine learning and statistical methods – to balance contamination control with energy efficiency.

Specifically, controlling airflow dynamics is the primary energy consumption factor in cleanrooms. AI can be used in cleanrooms to save energy through:

1. Dynamic Airflow Control (DAC)

Traditional standard design guideline requirements maintain a constant airflow regardless of the actual need or occupancy status. Therefore, AI can adjust airflow requirements in real-time based on particle counts, occupancy levels, activity types, and time of day. AI can lower fan speed through the VFD (variable frequency drive) while maintaining ISO cleanliness level. Liu et al. (2021) indicated that controlling recirculated airflow based on real-time particle count can reduce energy consumption of fans by 70%, which is considered a very significant energy saving.

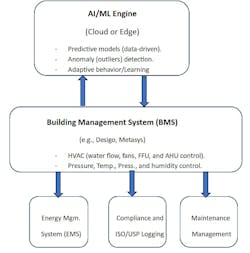

Machine Learning (ML) integrates data from various environmental sensors, including temperature, humidity, pressure differentials, airborne particle counts (both inside the cleanroom and outside air), lighting levels, and/or process operations. Machine learning, a part of AI, when used in cleanroom operations, integrates predictive analytics and statistical methods to predict contamination risks and adjust the HVAC operations accordingly.

For example, if a specific process tends to increase contamination, the AI proactively adjusts system operations through “learning” models before limits are exceeded. AI can forecast energy demands based on cleanroom operating schedules, heating, ventilation, and air-conditioning loads, and equipment operation profiles, and then optimize chiller, fan, and pump operations to flatten energy demand. This process supports integration with smart grids and demand-based electricity pricing to reduce costs.

2. Adjusting for Unoccupied Modes

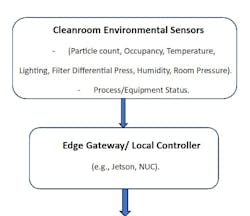

Cleanroom classification standards do not provide guidance for unoccupied mode ACH, but cleanliness levels. Since personnel and equipment/processes are considered to be the primary sources of generating particles, reducing airflow circulation during unoccupied times or process off times will significantly reduce energy consumption while ensuring cleanliness levels and positive pressurization of the room. See Figure 1 for reference on the simplified architecture of AI-driven cleanroom operations control.

3. Zone Control Management

Instead of treating the entire cleanroom (in larger cleanrooms) uniformly, AI enables zonal airflow management, such that more airflow is directed towards the higher levels of particle concentration sources, where people and/or processes are, and less airflow in unused or lower-risk activity areas. Zone control will reduce airflow requirements without risking contamination. This function will require engineers, architects, and owners to collaborate on cleanroom equipment/process locations and overall design layout.

4. Predictive Maintenance

AI analyzes trends in airflow resistance, filter pressure drops, and loading, as well as overall HVAC components and sensor performance. For example, AI schedules filter changes based on feedback from pressure differential across the filter. Additionally, AI schedules equipment services before breakdown or inefficiencies occur. This function prevents energy waste by running the system efficiently, which results in enhanced system performance and increased equipment lifetime. Moreover, the AI-predictive maintenance function can enhance cleanroom operations through a fail-safe condition as well as alarming users through continuous control of containment.

Conclusion

In this article, we have defined energy intelligence as a real-time, dynamic, and proactive behavioral control and adjustment of engineered systems. In addition, we have demonstrated that the use of AI in cleanroom design and operation is promising and can be used to save a significant amount of energy. AI can optimize the distribution of airflow while maintaining precise cleanliness levels and indoor environmental factors.

Moreover, AI can extend the service life of equipment and components. AI might employ machine learning and adaptive, proactive intelligent strategies to predict and optimize cleanroom operations for intelligent and energy-efficient systems. Designers and engineers should leverage AI to develop innovative solutions to help reduce the growing demand for energy and carbon reduction, all while ensuring compliance with industry standards.

References

1- Farzaneh, H., Malehmirchegini, L., Bejan, A., Afolabi, T, Mulumba, A., & Daka, P. (2021). Artificial intelligence evolution in smart buildings for energy efficiency. Applied Science. doi: 10.3390/app11020763

2- Liu, J., Zhang, L., Yang, J., Chen, Y., & Zhang. X. (2021). Study on pressure control and energy saving of cleanroom in purification air conditioning system. Energy and Buildings. doi: 10.1016/j.enbuild.2021.111502

3- Zhao, W., Li, H. & Wang, S. (2023). Energy performance and energy conservation technologies for high-tech cleanrooms: State of the art and future perspectives. Renewable and Sustainable Energy. doi: 10.1016/j.rser.2023.113532

4- Zhuang, C., Shan, K, & Wang, S. (2021). Coordinated demand-controlled ventilation strategy for energy-efficient operation in multi-zone cleanroom air-conditioning systems. Building and Environment. doi: 10.1016/j.buildenv.2021.107588

####

About the authors

Zuhair Hasan, PhD, P.E., LEED AP. Is an engineering consultant in Atlanta, GA. Dr. Hasan is a best-selling author and seasoned mechanical engineer with over 27 years of demonstrated history of working on government and mission-critical facilities. He is a sustainability advocate with several publications in the fields of engineering and leadership.

Kurt Burrell, PE, HFDP, is a Senior Mechanical Engineer with over a decade of engineering consulting experience across healthcare, aerospace, energy, government, and industrial projects. He is passionate about advancing sustainable engineering practices and applying innovative solutions to improve healthcare building performance and patient outcomes.

Disclaimer: The views presented in this article are those of the authors only and not that of their employers.